Features:

| - Single cell voltage range: 1.2V ~ 1.6V (depending on Vanadium electrolyte composition)

- Cell current density: 40 ~ 100 mA / cm^2 ( maximum 4.9A of possible current draw for a 7cm x 7cm reactive area)

- Manifold Blocks are made of anti-corrosive PTFE materials to withstand acids

- The large reactive area provides uniform and reliable test data

- Cathode materials are changeable according to the test conditions

- Easy assembly and disassembly

|

Reactive Area - Multiple Configurations

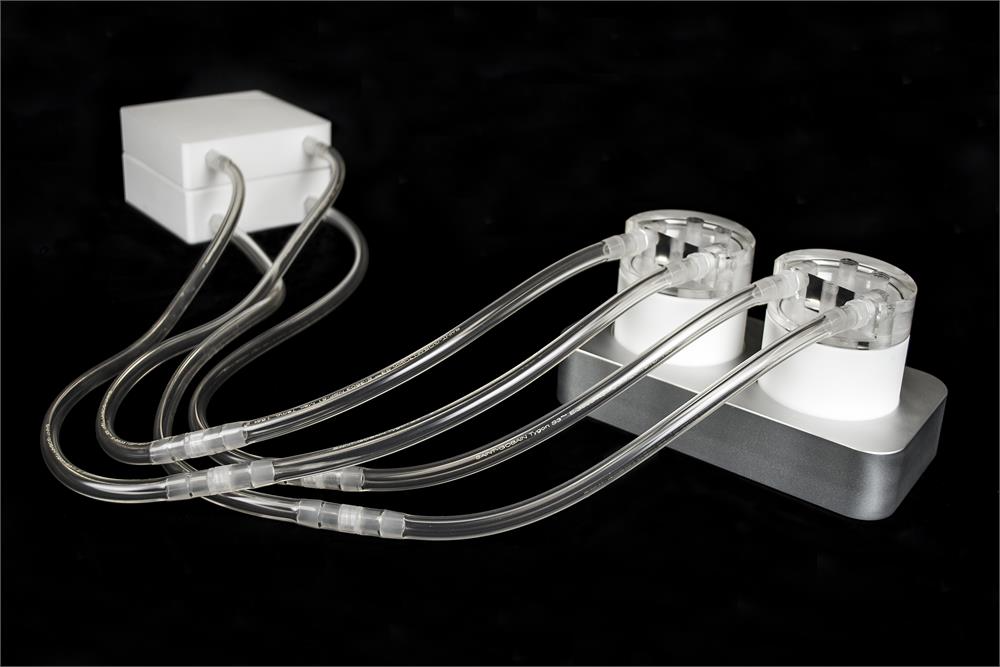

| - Standard cell comes with 3 interchangeable frames and gaskets for testing multiple parameters (please click the bottom left picture below for details):

- Custom reactive area sizes up to 7cm x 7cm can be requested at an extra cost

|

| Compression Pressure | - 87 PSI (0.6Mpa), ~300KG Force is recommended

- 116 PSI (0.8Mpa) Max.

|

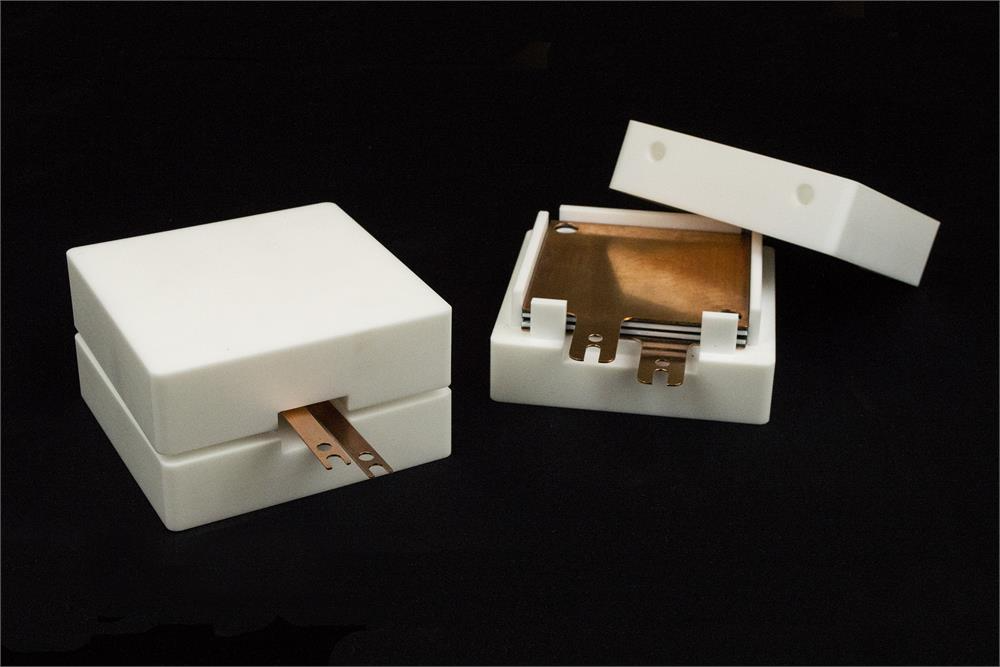

Unit Cell Internal Structure (all components are included)

| All components, Manifold Blocks, Current Plates, Bipolar Plates, Gaskets, Frames, Carbon Felts, Membranes, O-Rings, liquid inlet, and outlet ports, are included for immediate use. Please click here to order extra Internal Components if it is needed.

|

Bipolar Plates

| - High electrical conductivty, chemical resistance, and high mechanical strength for toughness

- These highly flexible plates offer performance comparable to conventional graphite plates BUT have excellent resistance to breakage and have fewer defects

- Only ~0.7mm in thickness, this keeps cells thinner when stacked compared to graphite plates ( porous and brittle in nature; needs to be thick structurally)

- Needs frequent replacement, please order from the "Related Products" category below

|

External Dimensions

|  126mm (L) x 126mm (W) x 67mm (H) 126mm (L) x 126mm (W) x 67mm (H)

|

Application Notes

Vanadium Redox Flow Cell Sketch

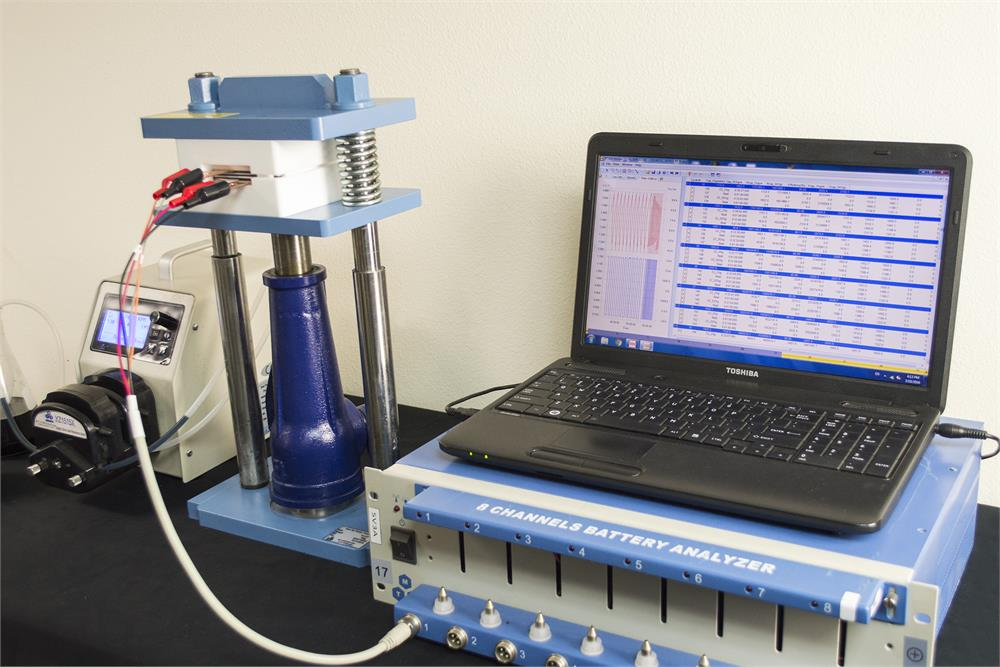

Photo Credit: Rahman, F.; Skyllas-Kazacos, M. Vanadium redox battery: Positive half-cell electrolyte studies. J. Power Sources 2009, 189, 1212-1219. | Procedure for Testing Flow Cell -- click the picture to enlarge:

MTI provides the complete setup at an affordable cost for the entire testing procedure. Please see images or related products below for more details.

- A jig or pressing machine is required to tightly press the cell together in order to suppress leakage of electrolyte solutions during live tests and also decrease ion/electron resistance. Please order a hydraulic jig separately form below or use your own jig -- WARNING: Never exceed a maximum pressure of 0.8MPa to avoid damage to the flow cell

- Peristaltic pump and battery analyzer are also available for making a low-cost DIY Flow Battery test system (please choose from related products below).

|

Relevant Articles & Videos

| Relevant Articles & Publications (click for links):

- "Vanadium Redox Battery" from http://www.vanadium-redox-battery.com/

- "Membranes for Redox Flow Battery Applications" Published: 19 June 2012

- "A Review of Metallic Bipolar Plates for Proton Exchange Membrane Fuel Cells: Materials and Fabrication Methods" Accepted: 13 June 2012

Videos (click to Watch):

A. HOW THE VANADIUM REDOX BATTERY (VRB) WORKS video credit: VanadiumCorp Resource Inc.

B. Making a vanadium redox flow battery, video credit: Energy Storage CDT (University of Southampton)

C. Video by MTI showing the Flow Cell in operation

A. B. C. C. |

| Optional Accessory |     |