Working Voltage

| INPUT: 24VDC

One UL/CSA listed 100-240VAC IN - 24VDC OUT power adapter is included. |

| Max. Power Consumption | 100W |

Traverse Speed | - 5 - 100 mm/sec variable

- Accuracy: 10mm/sec

|

| Stroke Length | - 10 - 550 mm adjustable by using the Adjustable Position Switch

|

| Max. Coating Dimensions | |

Vacuum chuck

| - Vacuum chuck made of Aluminum alloy with < 1 mm holes. The hole distance is around 14.8 mm.

|

Vacuum Pump (Optional)

(Remove the oilless pump from the standard pack Since 02/26/2016 ) |  |

Film Applicator

| |

| Dimensions | - Vacuum Chuck : 600mm(L) x 300mm(W)

- Product: 805mm(L) x 430mm(W) x 223mm(H)

Click the pic for more detail. Click the pic for more detail. |

Compliance

| - CE certified

- NRTL / CSA certification is available upon request at an extra cost.

|

| Warranty | One year limited warranty with lifetime support |

| Operation Video |    |

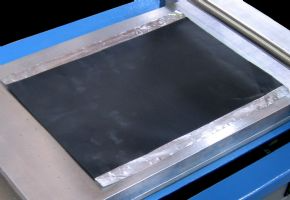

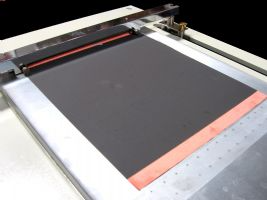

Application Notes | - Pic.1 and 2 show coated cathode and anode for Li-Ion batteries. Please click here to see how to

- It is recommended to operate the coater under a fume hood. (Click Pic.3 for detail.)

- You need a vacuum mixer to make uniform coatings (Click Pic.4 for detail.)

- You may need a Slurry Viscosity Tester to make coatings consistent (Click Pic.5 for detail.)

- You may need a vacuum oven to dry the films and remove the binder after coating. (Click Pic.6 for detail.)

- Rolling pressing is necessary to ensure good density and adhesion of electrode materials to the current collector substrate after coating. Please select a rolling press from here. (Click Pic.7 for detail.)

Pic.1 Pic.2 Pic.3 Pic.4 Pic.5 Pic.6 Pic.7 |

| Net Weight | 30 kg (67 lbs) |

| Shipping Dimensions | 48"(L) x 40"(W) x 37"(H) |

| Shipping Weight | 255 lbs |