| |

Inside Chamber Size

|

• Heated chamber: 200 x 200 x 200 mm (8x8x8 inch), 8 Liter.- • Energy-saving 1800 grade fibrous alumina insulation.

- • High purity Al2O3 coating.

|

Power | 7.5 KW

|

Voltage | AC 208 - 240V single phase; 50/60 Hz |

Current | 36 Amp (50 Amp air breaker is required) |

Continuous Working Temperature | 1650°C |

Maximum Working Temperature | 1700°C (< 1 hr) |

Heating Rate | 5°C / min |

Temperature Accuracy | +/- 1°C |

Thermocouple | two B type thermocouples (control thermocouple and secondary alarm thermocouple) |

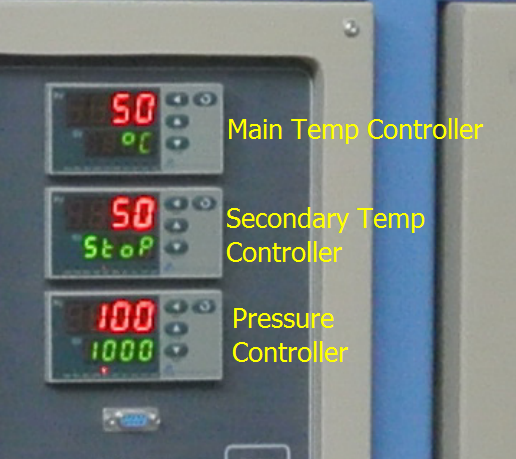

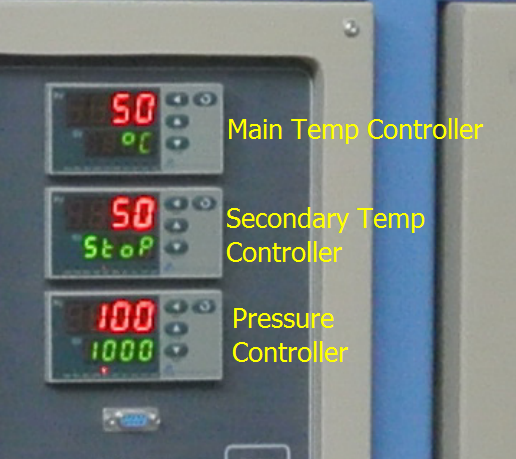

Temperature controller

|

Main Temperature Controller is used to setting and running the 30-segment heating program and provides the 1-level temperature alarm protection.

Secondary Temperature Controller reads the temperature from the secondary B type thermal couple, monitors the temperature during all process and provides the 2-level temperature alarm protection.

|

Pressure Control

|

• The pressure sensor and pressure controller are installed. It reads the chamber pressure and

controls the inlet and outlet gas valves respectively according to the pressure limit settings.

- • The pressure control can be used to perform the following functions:

- º Purging

- º Pressure control

- º High and Low-pressure protection

- • The pressure controllable range: -0.06 to 0.03Mpa.

|

Heating Elements

and

Working gas

|

• 6 pcs Mo Alloy coils (can only be used under inert gas, Ar is preferred; cannot be used under air

or oxygen at the temperature > 300°C).- • Optional: If using with pure oxygen gas, must use MoSi2 heating element with Ni power

connection wire。 Please call us in advance for the modification

|

Temperature Control

|

• PID automatic control via SCR (Silicon Controlled Rectifier) power control with phase angle fired,

current limiting resistor.- • 30 programmable segments for precise control of heating/cooling rate and dwell time.

- • Over-temperature protection and thermocouple failure alarm functions allow operation without

attendant(s). - • +/- 1ºC temperature accuracy.

- • RS485 Communications Port.

|

The temperature controller (optional)

|

• MTS02-Y Temperature control software kit (for YD518P series controllers) + brand new laptop

package is available at the options bar.

Click for the detail information about the MTS02-Y software kit. - • You may upgrade the temperature controller to the Eurotherm Temperature Controller which is fully

compatible with LabVIEW with +/- 0.1oC accuracy. This package includes a Eurotherm

programmer, a communication cable (RS485 - USB) and a software CD. Click the pic left to view

the full spec of the Eurotherm temperature controller.

|

Pressure Relief Valve

|

Spring Loaded Type Pressure Relief Valve

- • Cracking pressure is manufacturer pre-set at 0.066Mpa (relative pressure value).

- • Valve close pressure: 0.03Mpa (relative pressure value).

- • Max. Temperature 200ºC.

- • 35mm O.D barb fitting for gas exhaust.

|

Gas Flow Control and

Vacuum Valve

|

• Two flow meters (#1: 0~8L/min; #2: 0~4L/min) are installed on the front panel of the furnace.- • One heavy-duty vacuum pump (CE certified) is built on the bottom of the furnace.

- • Optional: You may order a (UL certified) pump at extra cost

(Pls click the right picture below to see specs).

( CE certified ) ( CE certified )  ( TUV certified ) ( TUV certified )

|

Water Cooling

|

• A 16L/min recirculating water chiller is installed in the bottom of the furnace for cooling furnace

sealing flange (CE certified only)- • MET Certification (UL 1450) for water chiller is available upon request at extra cost, please contact

our sales representatives for a quote.

|

Net Weight | 475Kg |

Shipping Weight | 1200 Lbs.

|

Product Dimensions

|  Please click the picture on the left to view dimensions: Please click the picture on the left to view dimensions:

|

Shipping Dimensions | 58" x 46" x 89" |

Warranty | One year limited warranty with lifetime support. (Consumable parts such as sample plates and heating elements are not covered by the warranty, please order the replacement at related products below.) |

Compliance

|

• CE Certified for the furnace, vacuum pump, and water chiller.- • NRTL (UL61010) or CSA certification is available at extra cost.( please click mark below to learn details

|

Application Notes

|

• For preserving the longevity of the furnace components, we recommend the heating rate not to

exceed 5 °C /min.- • The cooling rate shall also not exceed 5 °C /min.

- • Small cracks may appear on the surface of the refractory ceramics over extended use. This is a

normal occurrence and the cracks may be repaired with alumina coating. - • Please click here to learn how to DIY gas purging system.

- • The refractory block must be inserted before closing door.

- • Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the

pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

|

Warnings

|

• ATTENTION: Any damages caused by the use of corrosive and acidic gasses are not under the

coverage of MTI One Year Limited Warranty.- • In order to prevent oxidation/corrosion damages to the Mo heating elements, it is necessary to keep

a constant inert gas (Ar preferred) flow throughout the entire process. This is the most effective way

to carry out any by-products.

|

Operation Instructions

| |