• Wear-resistant tools. The resilience of titanium carbide makes its particles ideal for producing wear-resistant tools of various types,

including cutting tools and certain tools with abrasive surfaces.

• Abrasive bearings. Titanium carbide plays a critical role in the production of certain abrasive bearings.

• Coatings. Like many nanopowders, titanium carbide is particularly useful in producing specialized coatings. In particular, it’s used to

produce wear-resistant protective coatings and abrasive coatings. It is also used for conductive purposes in some cases.

• Conductive. Titanium carbide is fairly conductive, making it a useful additive for alloys and composite materials and in producing conductive coatings.

• Nucleation. Titanium carbide nanoparticles can be used as a nucleating agent.

• Optics. Used to produce certain titanium carbide ceramics used in a variety of optics applications.

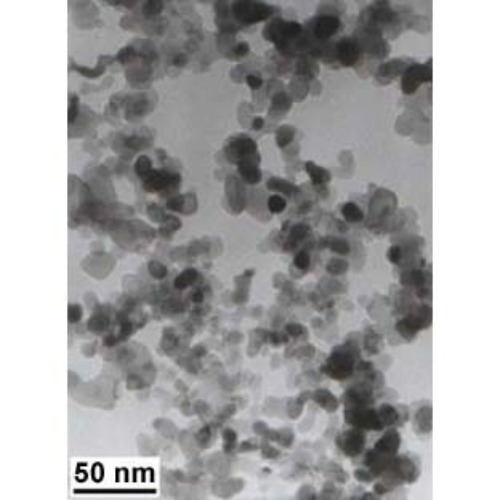

Titanium carbide ( TiC ) Nanopowder General Description

A fine black powder composed of 40nm nanoparticles of titanium carbide. This material is noteworthy for conductivity and its chemical inertness,

making it useful in a variety of applications across multiple domains. Research by engineers and nanoparticle researches into additional applications

continues to reveal new uses of titanium carbide nanoparticles each year. To find out more about available purities, particle sizes, and configurations

of titanium carbide nanoparticles.

Titanium carbide ( TiC ) Nanopowder Applications

• Wear-resistant tools. The resilience of titanium carbide makes its particles ideal for producing wear-resistant tools of various types, including

cutting tools and certain tools with abrasive surfaces.

• Abrasive bearings. Titanium carbide plays a critical role in the production of certain abrasive bearings.

• Coatings. Like many nanopowders, titanium carbide is particularly useful in producing specialized coatings. In particular, it’s used to produce

wear-resistant protective coatings and abrasive coatings. It is also used for conductive purposes in some cases.

• Conductive. Titanium carbide is fairly conductive, making it a useful additive for alloys and composite materials and in producing conductive coatings.

• Nucleation. Titanium carbide nanoparticles can be used as a nucleating agent.

• Optics. Used to produce certain titanium carbide ceramics used in a variety of optics applications.

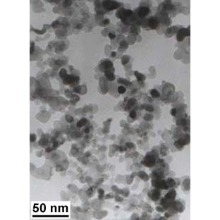

Titanium Carbide ( TiC ) Nanopowder General Description

A fine black powder composed of 40nm nanoparticles of titanium carbide. This material is noteworthy for conductivity and its chemical inertness,

making it useful in a variety of applications across multiple domains. Research by engineers and nanoparticle researches into additional applications

continues to reveal new uses of titanium carbide nanoparticles each year. To find out more about available purities, particle sizes, and configurations

of titanium carbide nanoparticles.

Titanium Carbide ( TiC ) Nanopowder Applications

• Wear-resistant tools. The resilience of titanium carbide makes its particles ideal for producing wear-resistant tools of various types,

including cutting tools and certain tools with abrasive surfaces.

• Abrasive bearings. Titanium carbide plays a critical role in the production of certain abrasive bearings.

• Coatings. Like many nanopowders, titanium carbide is particularly useful in producing specialized coatings. In particular, it’s used to

produce wear-resistant protective coatings and abrasive coatings. It is also used for conductive purposes in some cases.

• Conductive. Titanium carbide is fairly conductive, making it a useful additive for alloys and composite materials and in producing conductive coatings.

• Nucleation. Titanium carbide nanoparticles can be used as a nucleating agent.

• Optics. Used to produce certain titanium carbide ceramics used in a variety of optics applications.