Product Properties

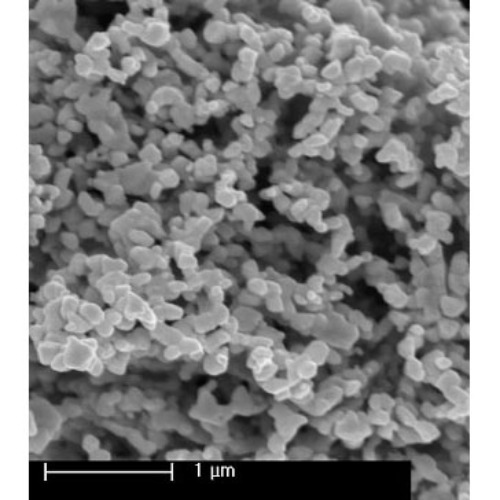

Tungsten Carbide Nanoparticles/ Nanopowder (WC, 99.95%, 80 nm)

WC Nanoparticles Particle Size: 80nm

WC Nanoparticles Crystal Structure: Hexagonal

WC Nanoparticles Bulk density: 3.2 g/cm3

WC Nanoparticles True density: 15.50 g/cm3

WC Nanoparticles Specific Surface Area: 60 m2/g

WC Nanoparticles Melting Point: 2870C

WC Nanoparticles Boiling Point: 6000C

Health and Safety

Hazard Statements | N/A |

Transport Information | N/A |

Suggest equipment | Eyeshields, Gloves, type N95 (US), type P1 (EN143) respirator filter |

Tungsten Carbide ( WC ) Nanopowder General Description

This material is a fine powder composed of tungsten carbide particles of approximately 80nm diameters, hexagonal in structure. Acid-resistant, insoluble

in cold water, and possessing a high elastic modulus, tungsten carbide nanoparticles are useful for generally resilient coatings, composites, and similar applications.

Tungsten Carbide ( WC ) Nanopowder Applications

- • Alloys. Due to the inherent hardness of this material, its an ideal component for creating various super fine hard alloys. It’s also of value in

producing certain alloys of tungsten.

- • Nanocomposites. The properties of this material make it valuable in producing certain nanocomposites, particularly those which need to be

exceptionally wear-resistant.

- • Abrasion-resistant. Materials with a need for abrasion-resistance can be enhanced with tungsten carbide nanoparticles as either a component

material for a composite or as part of an abrasion-resistant spray.

- • Wear resistant. The hardness of this material makes it ideal for producing wear-resistant composite materials and coatings.

- • Tools. Various tools which need to be chip-resistant or wear-resistant can be produced using tungsten carbide as a coating or material component,

etc. In particular, this material is widely used in the manufacture of mining equipment.

- • Corrosion-resistant coatings. In addition to value in wear and abrasion resistance, tungsten carbide nanoparticles can also be used to produce

corrosion-resistant coatings.