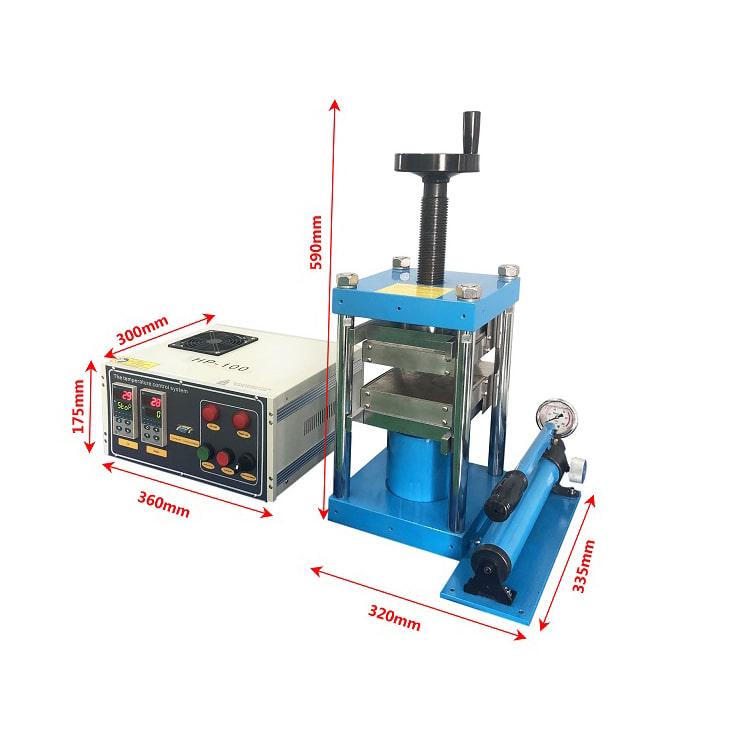

Hydraulic Press |

• Hydraulic pump and hydraulic cylinder are separated for easy replacement- • Max. Force: 24T

- • Manual operation

|

Max. Working Pressure |

Gauge Displayed Pressure Value (MPa)

| 5 | 15 | 25 | 35 | | Actual Force Applied on the Hydraulic Cylinder (Ton) | 5.5 | 11.7 | 18.5 | 25.5 |

- • The actual force applied to the Hydraulic Cylinder (Ton) equal to the force applied to your working piece

- • For calculating the actual pressure (MPa) applied on your working piece, please follow the equations

below: - • P = T/(πr^2) x g x 10

- º P: Pressure (MPa) applied to your working piece

- º T: Force (Ton) applied to the Hydraulic Cylinder

- º g: Standard gravity. g ≈ 9.8 m/s2

- º π: ~3.14

- º r: Radius (cm) of the working piece

- º *1 Metric Ton = 1000 kg; 1 MPa ≈ 10 kgf/cm2

|

| Pressure Gauge | - • Measuring Accuracy is +/-1.25 kN

|

Heated Platen Area

|

• Platen Area: 135 mm x 135 mm - • Material: Harden Cr12MoV alloy

- • Surface: Flattening with CNC grinding

|

Max. Travel Distance

|

• 40 mm - • Do not raise the bottom cylinder (piston) more than it's maximum traveling distance (80 mm)

|

Max. Working Temperature |

• 450°C continuous with water cooling- • 500°C for less 30 minutes

|

Heating Rate & Cooling Rate

| |

Water Cooling Jacket

|

• Two water cooling jackets are built on the back of the top and bottom heating plate separately with 1/4"

water pipe connectors. Such a configuration allows you to cool the sample as soon as the hot pressing

process is completed. - • Please consider using one recirculating water chiller to save water and protect the environment (order

separately by click picture below) - • You may order the electric hydraulic pump for automatic pressure control. (Pic below 3)

-

|

Temperature Control |

• Two digital controllers are installed in one box with 30 segments programmable and auto-tune faction- • Temperature accuracy ±2°C.

|

Power Requirement |

• 208 - 240 VAC, 50/60Hz, single phase- • 2.5 kW max.

- • 15 A circuit breaker is required for 220 V, 5' length power cable included, but no plug

|

Compliance

|

- • CE Certified for the whole furnace

- • NRTL (UL 61010) or CSA Certification is available upon request, additional charges will apply

|

Machine Dimensions

Pictures |

|

Shipping Weight &

Dimensions

| 600 lbs; 47" x 39" x 41"

|

Operation Instructions |

|

Warranty |

• The pressing machine was quality inspected in the USA, lifetime support is provided- • One year limited standard warranty (Extended warranty is available up to 5 years at an extra cost)

|

Application Note |

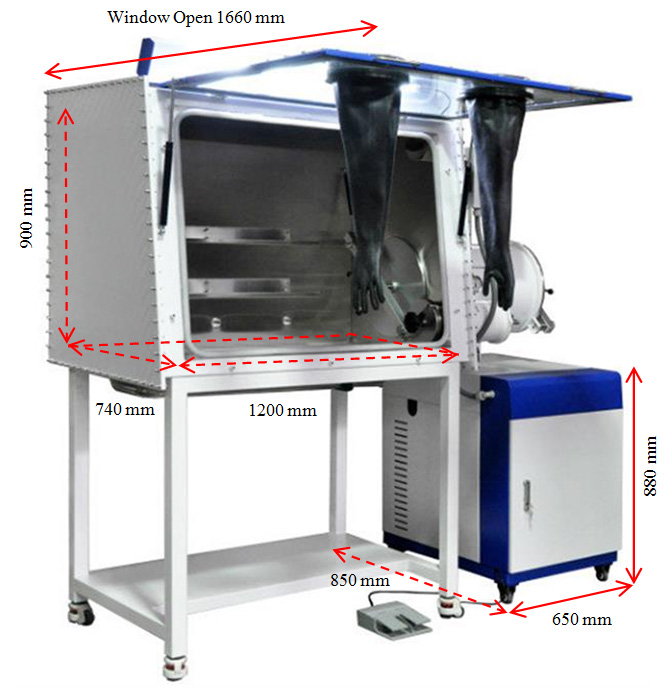

• The Hot Press can be located inside of a glovebox which temperature controller and the pump will be

put outside of the glove box

-

|