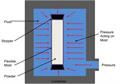

Pressure Vessel

|

• 22mm ID. x 90mm Height- • max available sample height 70mm

- • Made of high strength alloy with stainless steel protective jacket

- Spare die is available for existing customer

|

| Max. Hydraulic Pressure in Chamber |

300 MPa -- continuous holding

380 MPa --- less than 5 minute

|

Gauge Pressure Value to

Force Conversion

Optional digitalmeter with alarm

|

Gauge Displayed Pressure Value (Bar) for 87 mm Dia. Hydraulic Press

| 100 | 200 | 300 | 387 | | Optional Digital Gauge Displayed Pressure Value (Mpa) for 87 mm Dia. Hydraulic Press | 10 | 20 | 30 | 38.7 | | Actual Force Applied on the Hydraulic Press (Ton) | 3.8 | 7.6 | 11.5 | 14.7 | | Pressure Applied to CIP Vessel ( Mpa) vs 22mm vessel cylinder | 98 | 196 | 296 | 380 |

• Notes: - • The actual force applied on the Vessel Cylinder (Ton) equal to the force applied to your working piece

- • Digital pressure Gauge ( 60Mpa ) with Alarm is available upon request ( Click picture to see specs & cost)

- • For calculating the actual pressure (Mpa) applied on your working piece, please follow the equations in

below: - P = T x g x 10 / (πr^2)

- º P: Pressure (Mpa) applied on your working piece

- º T: Force (metric ton) Applied on the Pressure Vessel Cylinder

- º g: Standard gravity. g ≈ 9.8 m/s2

- º π: ~3.14

- º r: Radius (cm) of the Pressure Vessel (1.1 cm)

|

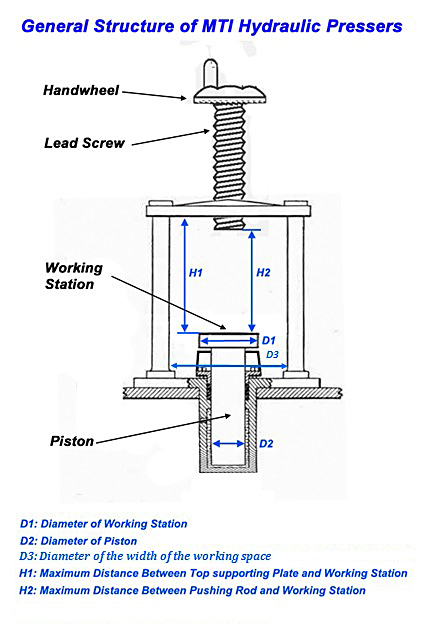

| Hydraulic Machine | |

Botton Cylinder Traveling Distance

| 20mm maximum, the bottom cylinder (piston) in the cross-section illustration in the dimension section below |

| Operation Temperature | 10 - 40°C |

The dimension of Working Space

| D1: 120mm D2: 70mm D3: 125mm

H1: 260mm H2: 220mm

|

Overall Dimension

|

200L x 330W x 715H, mm

|

| Net Weight | 70 Lbs |

| Shipping Weight & Dimensions | |

| Compliance | CE Certified |

| Warranty |

• One year limited with lifetime support

- • Rusting and damage due to improper storage condition or maintenance are not covered by warranty

|

| Operation Video & Instructions |

|

| Application Notes |

|

| Warning |

• Never let the press hold the target pressure be longer than 8 minutes,- • It's normal that the target pressure decreases a little bit during the pressure holding time, so never press

the red nor the green button in this period. - • Pressure must be completely released first, then make sure the hand wheel and the pressure release

valve has been tightened before pressing - • Do not raise the bottom cylinder (piston) more than it's maximum traveling distance. (20mm)

|