Working Power | 208 - 240 VAC, 50/60 Hz, Single Phase

6 KW ( 50A Air breaker required )

|

Compressed Air | 0.5-0.8 MPa is required (Air compressor not included. Please click here to order)

Attention: If a gas cylinder is used instead of air compressor(pic2), a two-stage pressure regulator(pic1) must be installed on the gas cylinder to limit the pressure within the required working range for safe operation. Click here to learn the installation of a gas regulator.

pic1 pic1  pic2 pic2

|

Reeling/Unreeling Diameter | 250mm O.D Max. |

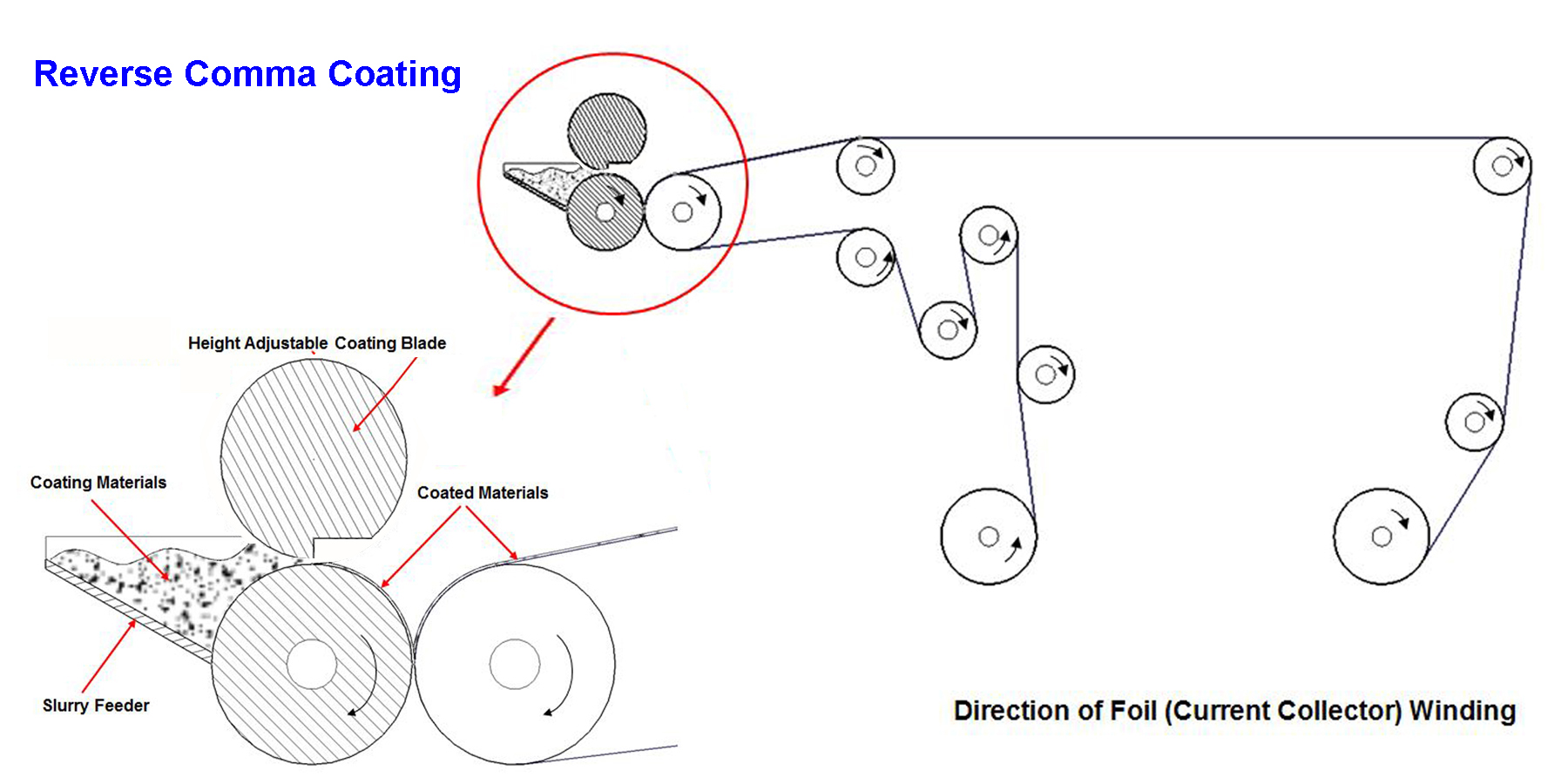

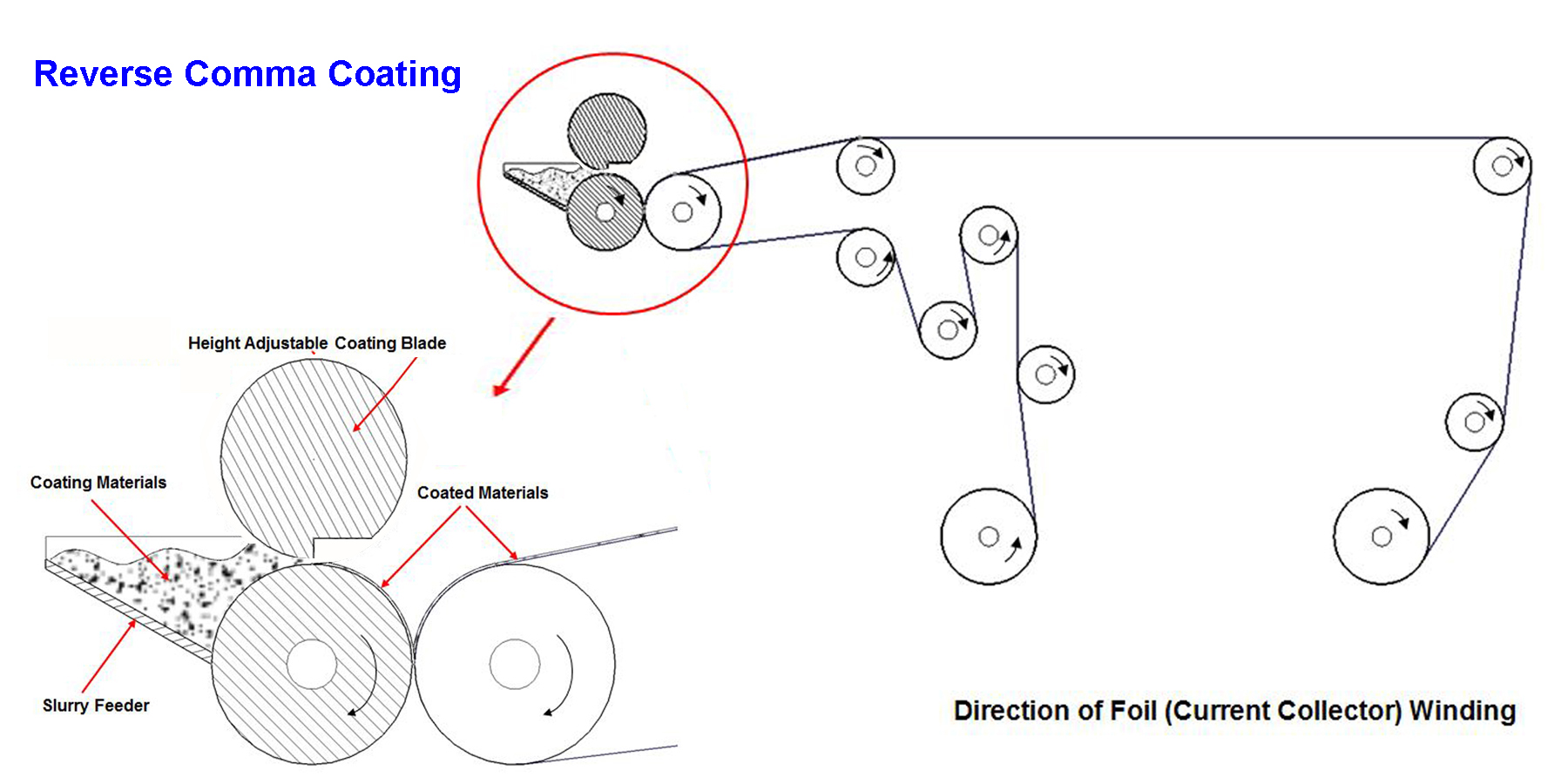

Coating Heads (please select in the Product Options)

- Doctor Blade

- Slot Die

- Micro-Gravure

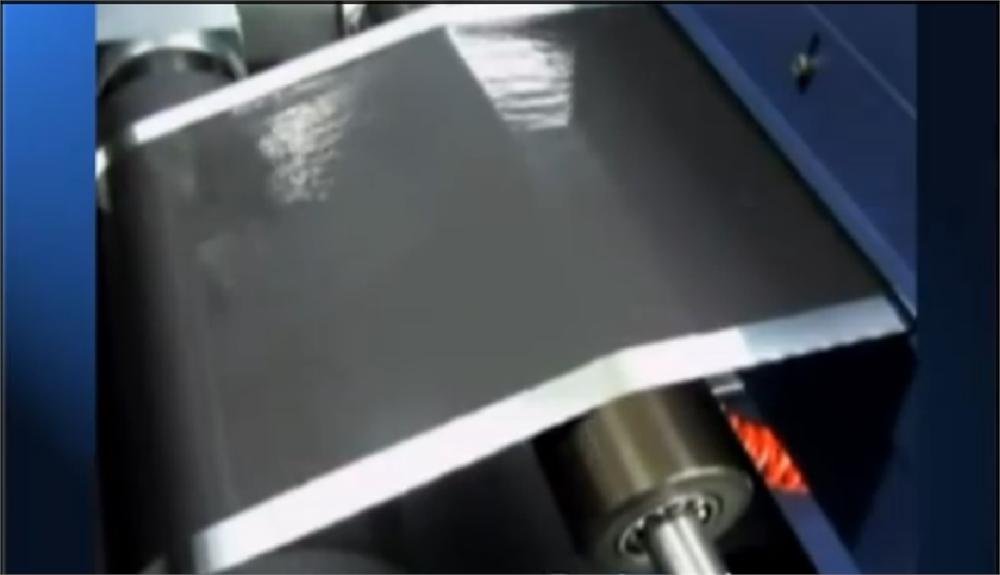

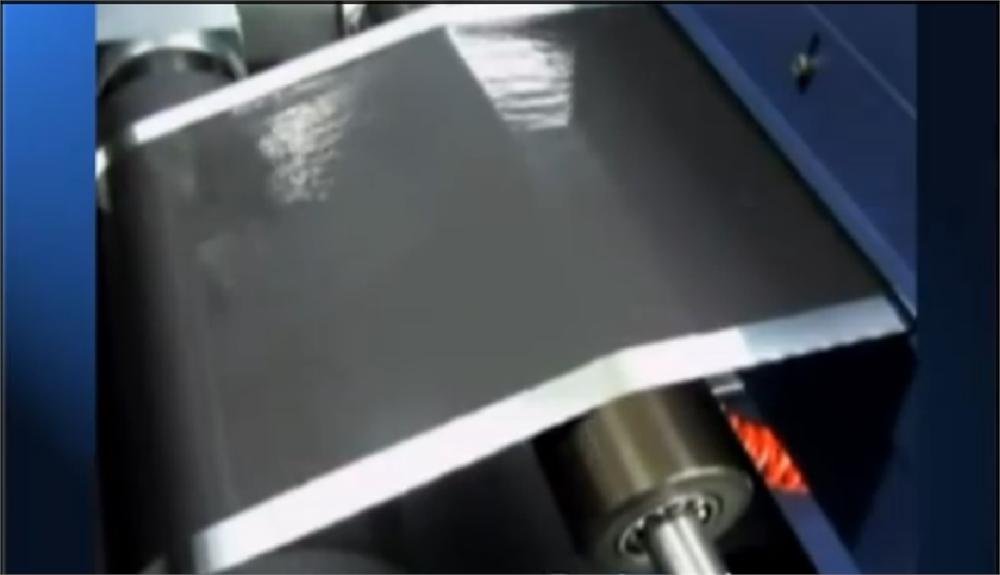

| Doctor Blade Coating

(Reverse Comma Blade)

| - Two available coating modes (continuous and intermittent) selectable on the control panel.

- Coating thickness range: 10~200um ( dried film )

- Coating width and length: 180mm W x 5000mm L Max. (single side coating)

- Typical slurry viscosity range: 500~10000 mPa.s

- Precision: ±5μm

- MSK-155 auto-slurry feeder with 2 liters tank is included, please click underline to view details.

|

Slot Die coating

| - The slot die is perfect for uniform film coating of 1 micron and up to 300-micron thickness. By changing the shim size with various patterns, you would be able to produce continuous, intermittent, or even grid coatings that match the shim patterns. Please refer to the pictures in below for more details:

- MSK-156 slurry feeding screw pump with 4 liters tank is included, please click underline to view details

- Minimum thickness & precision: 1 µm ( dried film ), ±1%

- Coating width and length: 150mm W x 5000mm L Max. (single side coating)

- Typical slurry viscosity range: 200~10000 mPa.s

- Attention: The final coating thickness is dependent on a wide range of parameters such as slurry viscosity, solid particle size, solid content, shim thickness, foil rolling speed and slurry feeding rate. Therefore, we are not able to guarantee that 1-micron level film is achievable for all kinds of slurries. For further discussion, please let us know your slurry specs and coating thickness requirement.

|

Micro-Gravure Coating

| - Continuous and intermittent coating mode is available for the user.

- Coating thickness range: 2~3um ( dried film )

- Coating width and length: 180mm W x 5000mm L Max. (single side coating)

- Typical slurry viscosity range: 30~2000 mPa.s

- MSK-155 auto-slurry feeder with 2 liters tank is included, please click underline to view details.

|

Drying Mechanism (please select in the Product Options) - Convection Heating

- Infrared Heating

- UV Curing

| Convection Heating

( standard package) | - Airflow rate:3.3/2840 ( cm³/min @ RPM ) max., flow rate adjustable

- Drying temperature: 150°C max.

- Power Consumption: 3KW max.

- Heater length: 500mm

|

Infrared Heating | - Drying temperature: 150°C max.

- Power Consumption: 2.1KW max.

- Heater length: 500mm

|

UV Curing | - The power and wavelength of the UV lamp can be customized according to customer's specific requirements.

- Heater length: 500mm

|

Film Lamination/

Calendering (Optional) | - The system can be integrated with laminate which laminates the ion exchange membrane/separator film onto the electrode as the film rolls out.

- Calender is also an option besides the laminator in the case that a higher coating density with reduced film thickness is required.

- Roller size: Φ150x200mm

- Roller surface: , Ra<0.4, circular runout +/-2um

- Hardness: ≥HRC60

- Material: Chromium-plated stainless steel

- Dual micrometer for accurate thickness adjustment in the range 0.5 - 2 mm

- Note: Heatable rollers (max. 100C) are available upon request. Please contact our engineering dept. for more details

|

Product Dimensions | L1260mm x W850mm x H1600mm |

Compliance

| - CE Certified All electric components ( >24V) are UL / MET / CSA certified

- NRTL or CSA certification is available upon request at the extra cost

- IP: ZL 201510564515.9

|

Warranty | - One Year limited warranty with lifetime support

- Rusting and damage due to improper storage condition or maintenance are not covered by warranty

|

| Operation Manual & Video |

|

| Application Notes | - Customers are welcome to visit our facility to receive technical training before shipping of equipment (Please schedule an appointment with us in advance)

- On-site Training is available for customers within the US only (Expenses will be covered by customers)

|

| Net Weight | 1000 kg (2200 lbs) |

| Shipping Dimension | L1560mm x W1150mm x H1900mm |