| Working Voltage | 220V AC, 50/60Hz, three Phase |

| Max. Power Consumption | 1KW |

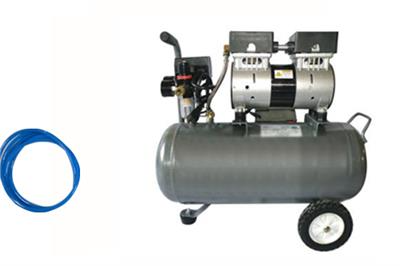

| Air Pressure | 0.5 MPa~0.8Mpa is required (Air Compressor is not included, please click here to order)

Attention: If a gas cylinder is used instead of air compressor(pic2), a two-stage pressure regulator(pic1) must be installed on the gas cylinder to limit the pressure within the required working range for safe operation. Click here to learn the installation of a gas regulator.

pic1 pic1  pic2 pic2

|

| Compatibility | Standard grooving capability for 18650 case

Note: CR123 / 18650 / 26650 / 32650 / AA is available upon request, please contact us for more details. |

| Control | User-friendly HMI with PLC touch screen control ensures easy program setup

|

| Grooving Dimensions | Micrometer assisted grooving depth & height adjustment

Depth: 1 - 2.0 mm

Width: 1 - 1.5 mm

18650 Grooving Dimensions for reference

- A: 3.4 - 3.7 mm

- B: 13.6 - 14.2 mm

- C: 1.3 - 1.5 mm

|

| Grooving Accuracy | +/- 0.1 mm |

| Grooving Blade Life Span | >1 million times |

| Grooving Force | 6kgf/cm^2 |

| Compression Ratio | Percentage in height: 80%

|

Productivity

| - Material feeding conveyor is able to load upto 22 pcs per batch

- 30 pieces per minute

|

Product Dimensions

| W1080mm*D660mm*H1600mm

|

Net Weight

| 1000lbs

|

| Compliance | CE Certified |

| Warranty | - One year limited with lifetime support

- Rusting and damage due to improper storage condition or maintenance are not covered by warranty

|

| Operation Video |

|

| Optional Function | With the optional slurry SS reservoir and feeding pump, it can apply a thin layer of insulation coating on the "neck" after grooving to further enhance the sealing quality between the cap and case body. This approach can prevent the electrolyte leaking due to the gasket aging on the cap. Please contact us for more details. |

| Application Notes | - Customized die for other cylindrical cell types is available upon request

- It is necessary to seal the cap of the cylindrical case by using the MSK-510-AR18650 sealing machine after grooving the opening end

- Each type of cylinder cell can only be grooved specifically by the certain model of this equipment. Please select the type of cylinder cell in the Product Options drop box to check the model number and price for the corresponding grooving die of each cylinder cell type

- Please check the chart below to order the cylindrical cases.

|