Furnace Construction

| - Double shell casing with three cooling fans

- High purity Alumina fibrous insulation for max. energy saving

- Gear DC motor drives quartz tube with variable speed 0 - 5 RPM

- Split cover enables faster cooling and easy operation

- Compact size for space saving

|

Heating Zone length

| Two zones: each zone length 4" (100 mm), total 8" (200 mm) heating zone Constant temperature zone: 100 mm within +/-2oC if two zones at the same temperature

|

Processing Tube

| - 2" Fused quartz processing tube with mixing blade in the center, please click the pics below for details:

Four Mixing Blades Four Mixing Blades  Tube dimension Tube dimension

|

Gas Fittings

| - Inlet Fitting: Elbow Push-in connector for 6mm O.D tube; Outlet Fitting: Elbow Push-in connector for 12mm O.D tube

- Option parts: If do not want plastic connector, please upgrade to Inline Swivel Head

|

| Max. Working Temperature | 1100°C for continuously 1200 °C Max for < 2 hours |

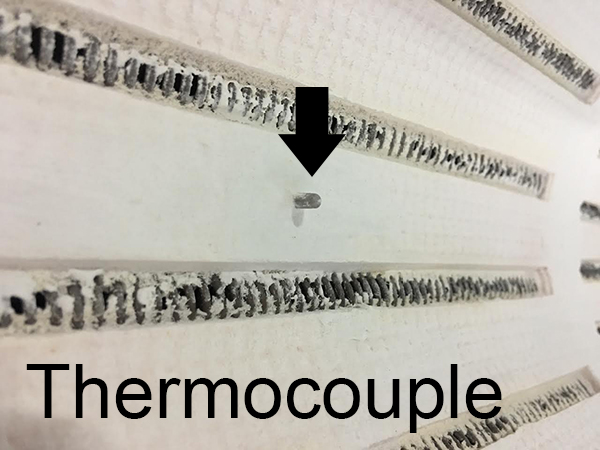

Temperature Control | - Two PID digital temperature controller with 30 segment programmable, +/- 1°C

- Each heating zone's temperature is controlled independently

- Two Omega K type 3mm OD x 6" L with high-temperature tolerance (220°C) connector

|

Tube rotating Speed | 0 - 5 RPM variable |

Furnace tilt angle | - No tilting function

- You can add a spacer at the bottom of the furnace to tile furnace

|

Chamber pressure | 4.5x10-2 torr (<0.1mtorr/s leaking rate if close all the valves to airtight the tube chamber)

|

Power | 1.5 KW Max |

Voltage | - 110V AC or 208 - 240V with 3000W Transformer

- single phase (30 A Breaker required)

|

| Warranty | One-year limited warranty (Consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty, please order the replacement at related products below.) |

Compliance

| - CE Certified

- NRTL (UL61010) or CSA certification is available upon request at an extra cost

|

|

Furnace dimension: |  |

Product net weight | 25 Kg

|

| Shipping dimension |

|

| Shipping weight | 150 lbs

|

Application Notes | - The concept of continuous power feeding and processing can be realized by the use of Magnetic Fluid Sealed Swivel Coupling in line with Volumetric Feeder and Rotary Furnace. Please view the assembling approach diagram and video below

- For CVD coating, you may choose our multi-channel Gas delivery system and automatic feeding system as Pic below

-

|

| Article | |

| Operation Video |

|

| Warnings | - The tube furnaces with quartz tube are designed for using under vacuum and low pressure < 0.2 bars / 3 psi / 0.02 Mpa

- Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

- Vacuum limit definition for all quartz tube furnaces: * Vacuum pressures may only be safely used up to 1000°C

|