Working Voltage

| INPUT: 24VDC

A UL/CSA listed 100 or 220VAC IN - 24VDC OUT power adapter is included. |

| Power | 120W |

| Traverse Speed | 10 - 80mm/sec variable |

| Stroke Length | 10 - 800mm adjustable by using Adjustable Position Switch |

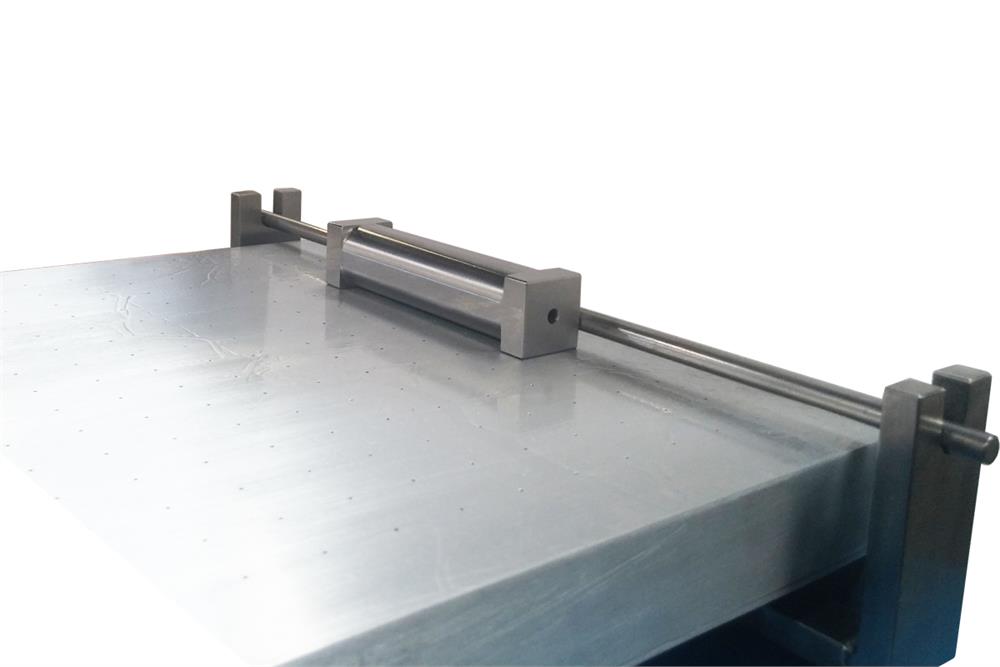

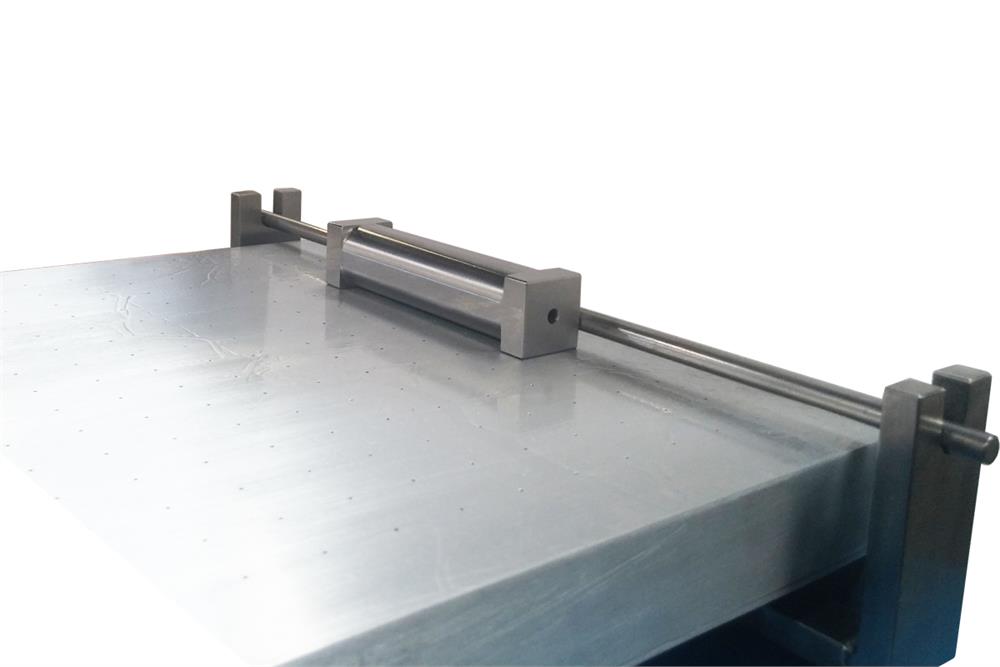

Platform

| - • Aluminum alloy flat vacuum chuck

- • Vacuum chuck Dimensions: 800mm(L) x 250mm(W) x

25mm(H)

|

Vacuum Pump (Optional)

(Remove the oilless pump from standard pack Since 02/26/2016 ) |

|

Film Applicator

|

• Built-in pushing bar for using micrometer adjustable

applicator.- • 180 mm width Applicator with micrometer adjustable

head included making coating up to 800mm(L) x

180mm(W) (Click picture below to see details)

Note: Thinnest film can be achieved is > 10 micron

(Click here to order other size film applicators)

|

| Max. Coating Area | 800mm(L) x 250mm(W) |

| Accuracy of Film thickness | +/- 0.01mm |

Application Notes

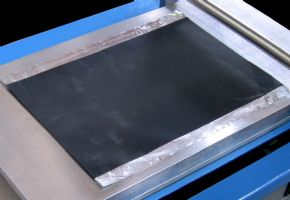

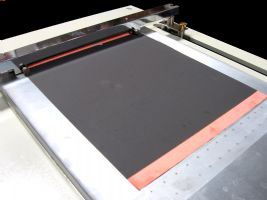

| - • Pic.1 and 2 show coated cathode and anode for Li-Ion

battery. Please click here to see how to coat an electrode

sheet. - • It is recommended to operate the coater under a fume

hood. (Click Pic.3 for detail.) - • You need a vacuum mixer to remove air bubbles

inside slurry and to make uniform coatings

(Click Pic.4 for detail.) - • You may need a Slurry Viscosity Tester to make

coatings consistent (Click Pic.5 for detail.) - • You may need a vacuum oven to dry the films and

remove binder after coating. (Click Pic.6 for detail.) - • Rolling pressing is necessary to ensure good density

and adhesion of electrode materials to the current

collector substrate after coating. Please select a

rolling press from here. (Click Pic.7 for detail.) - • For using other Film Applicator different from standard

package, customized Traverse Pusher required

ensuring the constant coating speed.

( Click Pic.9 for detail.)

Pic.1 Pic.1  Pic.2 Pic.2 Pic.3 Pic.3

Pic.4 Pic.4  Pic.5 Pic.5  Pic.6 Pic.6

Pic.7 Pic.7  Pic.8 Pic.8 Pic.9 Pic.9

|

Machine Dimensions

|

• Without heating lid: 960mm(L) x 370mm(W) x

240mm(H)- • With heating lid: 900mm(L) x 370mm(W) x 313mm(H)

|

| Net weight | 40 kg (90 lbs) |

| Shipping Dimensions | 48" x 40" x25" |

| Shipping Weight | 180 lbs |

Compliance |

• CE certified- • This machine is using 24VDC input power which shall

be exempted from the safety inspection (according to

UL61010/SPE-1000 regulation). However, with

additional certification fee, MTI can arrange NRTL to

perform UL/CSA inspection and label the machine per

customer's request. Please contact us for the quote.

|

| Warranty | One Year limited with lifetime support |

Operation Video

&

Instructions |

Video for MSK-AFA-L800 Video for MSK-AFA-L800-H |