Compact Structure |

|

Input Power |

• Single-phase 220 VAC 50 / 60 Hz- • 2000 W (including a vacuum pump and water chiller)

|

Source Power

|

• Two sputtering power sources are integrated into one control box

(Click picture below to see detailed specs)

- º DC source: 500 W power for coating metallic materials

(Pic 1) - º RF source: 300 W power, 13.56 MHz frequency for coating

non-conductive materials (Pic 2)

-- Pic 1 -- Pic 1  -- Pic 2 -- Pic 2

|

Magnetron Sputtering Head

|

• Two 2" Magnetron Sputtering Heads with water cooling jackets and

shutters are included (Click 1st pic from left.

- • One Sputtering Head Model also available on this product page (in

product options)

- º One is connected to DC source for coating metallic

materials - º The other one is connected to the RF source for non-

conductive materials - º Target size requirement: 2" diameter

- • Customized coater: Two DC heads without RF; two RF heads

without DC; 3 RF heads are available upon request

- • Optional: 148 cm RF cable can be ordered at extra cost for the

replacement (Click the 1st pic from right to order)

|

Vacuum Chamber

|

• Vacuum chamber: 300 mm Dia. x 300 mm Height, made of stainless

steel

- • Viewport: Two pieces of 100 mm Dia. glass. One fixed; one

detachable for cleaning and replacement

- • Hinged type lid with pneumatic power pole allows easy target

change

|

Sample Stage

|

• The sample holder is a rotatable and heatable stage made of the

ceramic heater with copper cover

- • Sample holder size: 140 mm Dia. for. 4" wafer max

- • Rotation speed: 1 - 20 rpm adjustable for uniform coating

- • The holder temperature is adjustable from RT to 500 °C max

(2 hr max) with accuracy +/- 1.0 °C via a digital temperature

controller

|

Gas Flow Control

|

• Two precision mass flow controllers (MFC) are installed to allow

inlet of two types of gasses

- º Flow rate: 0 – 200 mL/min adjustable on the touch screen

control panel

- • Air inlet valve is installed for vacuum release

|

Vacuum Pump Station

|

• A mobile pump station is included. The sputtering coater can be

placed on top of the station

- • High-speed turbopump at speed 80L/S is combined with a two-

stage mechanical pump (220 L/min) for max vacuum level and

faster pumping speed

- • Standard vacuum level connected with chamber: < 4.0E-5 Torr.

- • Optional at extra cost

- • If choose a 150L/S high-speed turbopump, a vacuum can reach

10-6 torr with a chamber ( 6x10-7 torr with baking)

- • For the ultra-high vacuum up to 10^-7 torr, a getter pump (100L/s

H2 & O2) is needed in addition to the turbopump. Please consult

our engineers for detailed customization.

-

150L/S high-speed turbopump 150L/S high-speed turbopump

Getter Pump Getter Pump

|

Water Chiller

|

• One digital temperature-controlled recirculating water chiller is

included. (Click picture to see details)

- º Refrigeration range: 5~35 °C

- º Flow rate: 16 L/min

- º Pump pressure: 14 psi

|

Optional |

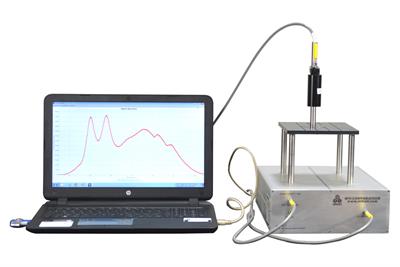

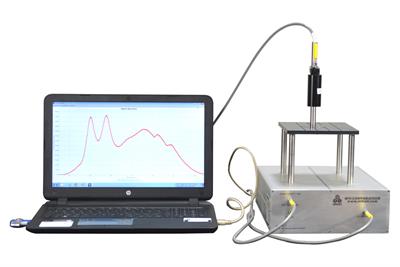

• Precise quartz Film Thickness Monitor is optional, which can be into

the chamber to monitor coating thickness with an accuracy of 0.10 Å

- • Precision Thin Film & Coating Analysis Systems - EQ-TFMS-LD is

available at extra cost

- • Various 2” oxide and metallic targets are available upon request at

extra cost. Silver epoxy and copper backing plates can be ordered

at MTI

|

Overall Dimensions

|

Lid closed: 48" × 28" × 32" Lid open: 48" × 28" × 37"

|

Net Weight of Coater | |

Shipping Weight & Dimensions

|

• Total 2 Pallets- • #1: 520 lbs, 52" x 40" x 50"

- • #2: 420 lbs, 48" x 40" x 45"

|

Compliance

|

• CE approval

- • MET Certification (UL 1450) is available upon request at extra cost,

please contact our sales representative for quote.

|

Warranty | - • One year limited warranty with lifetime support

|

Operation Instruction

|

|

Application Notes

Pic 1

Pic 2 |

• A two-stage pressure regulator (not included) should be installed on

the gas cylinder to limit the gas output pressure below 0.02 MPa for

safe usage

- • In order to remove oxygen from the chamber, MTI suggest you to

use 5% Hydrogen + 95 % Nitrogen to clean the chamber 2-3 times,

which can reduce the oxygen level to < 10 ppm

- • Please use > 5N purity Argon gas for plasma sputtering. Even

though 5N purity Ar usually contains 10 - 100 ppm oxygen and H2O

depending on the supplier. MTI suggest you to use gas purification

device to purify gas before filling in. (Click Pic #1 & #2 on the left to

order)

- • For best performance, the non-conductive targets must be installed

with a copper backing plate. Please refer to the instruction video

below for target bonding (Click Pic #3 below)

- • MTI supplies single crystal substrate from A to Z

(Click Pic #4 below to order)

- • MTI Sputtering Coaters have successfully coated ZnO on

Al2O3 substrate at 500 °C (XRD profile in Pic #5 below)

- • HIGH VOLTAGE! Sputtering heads connect to high voltage. For

safety, the operator must shut down the RF / DC generator before

sample loading and target changing operations

- • DO NOT use tap water in water chiller. Use coolant, DI water,

distilled water, or anti-corrosive additives with water

|