Pneumatic Press

| - Max. Load: 9KN ( 900 Kg)

- Pneumatic cylinder travel distance 200 mm Max.

- Working area: 200 mm W x 150 mm D

- Max. working height: 0 - 110 mm

- Driven by any standard air compressor or inert gas tank, which is not included. 0.4~0.8Mpa of air pressure supply is needed. Please click the picture below to order.

- Attention: If a gas cylinder is used instead of an air compressor(pic2), a two-stage pressure regulator(pic1) must be installed on the gas cylinder to limit the pressure within the required working range for safe operation. Click here to learn about the installation of a gas regulator.

- Note: If used in the glove, an inert gas cylinder must be used for the gas source.

pic1 pic1  pic2 pic2

|

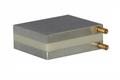

| Heating Plates | - Two heating plates with two independent single point temperature controllers

- Single point PID temperature control with +/- 1ºC accuracy

- Heated plate area: 200 mm W x 150 mm D

- Max. working temperature: 150°C (continuous)

- Heating Rate: 15°C/ minute Max.

- Power: 220V (50/60 Hz), 1200 W

|

Pressure Controller

| - Pneumatic cylinder bore size 125mm diameter.

- Digital pressure controller with PID tuning, which can keep the constant pressure at setting value.

- 30 segments programmable. (max working time: 9999 minutes for each segment)

- Pressure Accuracy: +/- 0.5 kg /cm2

- Optional: You may order the load cell below to calibrate the applied pressure force from time to time

|

Feed-Through (Optional)

| - If the press is used in a glove box, two separate feed-throughs are required

- One feed-through for gas tubes.($295.00/set)

- One feed-through for power and communication cords.($500.00/set)

- The feed-throughs are not included in the standard package, please contact us for more information.

|

Product Dimensions

| - Press: 245 L x 480 W x 620 H, mm

- Pressure Programmer: 250 L x 230 W x 120 H, mm

|

Compliance

| - CE approval

- NRTL or CSA certification is available upon request at an extra cost of $3500.00

- Calibration: Please use NIST certified load sensor to calibrate the pressure by yourselves. ( Please click the picture below to order:

|

| Warranty | One-year limited warranty with lifetime support (rusted and damaged parts due to improper storage condition or maintenance are not covered by warranty) |

| Application Notes | - It can be used as a jig for compressing pressure adjustable split test cell, please click the picture below for details:

compress-able coin cell compress-able coin cell  Compress-able pouch cell Compress-able pouch cell

|

Operation Manual & Video

|   |

| Net Weight | 80 lbs |

| Shipping Weight and Dimension | 135 lbs, 40"L x 25"W x 35"H |