Pressure | 6 metric tons ( 10 MP on pressure gauge ) Max. |

Hydraulic Pump | 12T manual pump is built-in on the bottom of the frame. The 24t Hydraulic pump can be ordered at extra cost. |

Bottom Hydraulic Cylinder Travel Distance | 25 mm |

Top Support Screw Adjustable Height | 150 mm |

Heating Chamber & Temperature Control & Pressure gauge

|

• Split furnace with 55mm diameter heating chamber- • Max. working temperature: 1000ºC

- • 30 segments programmable temperature controller with auto tune PID and over-heating protection

- • Digital Pressure Gauge with max. pressure setting ( click the pic below right to see detail specs)

|

Furnace Power Supply | Single Phase AC 208~240V, 1.2KW |

Machine Dimensions | 495 L*560 W*960 H mm |

Net weight | 350 lb |

Weight of shipment | 410 lbs with 48"x40"x46" dimension |

Optional Press dies & Pushing Rod for the hot pressing

|

• Pressing die and Pressing die supporting are not included, please prepare yourself.

(The suggesting pressing rod size is provided below picture. The size is work with MTI's pressing dies

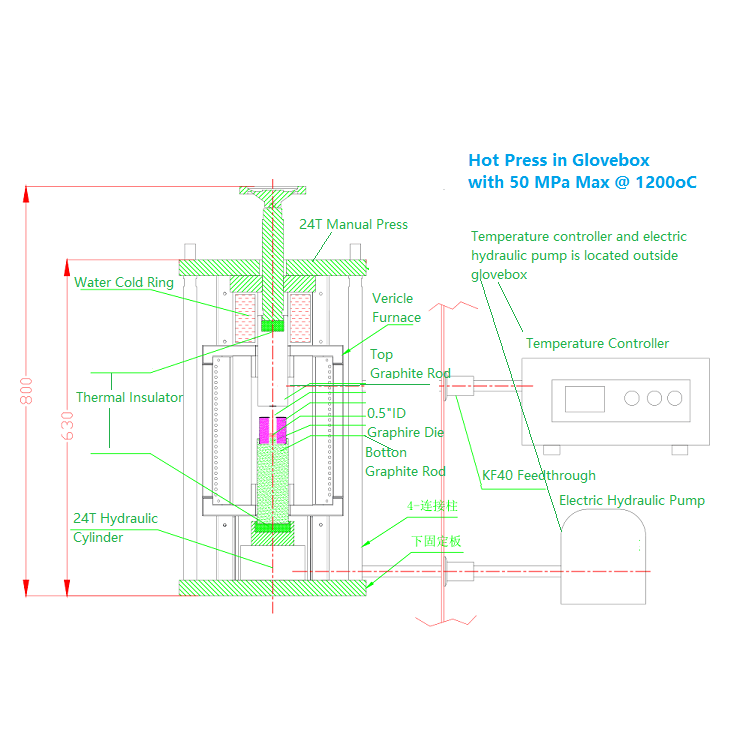

only.) - • Hot press in glovebox is available upon request at extra cost ( click pic below right )

-

- • Please click the picture below to choose a die based on Max.working temperature in air. For higher

temperature die, you may use Al2O3 or SiC die, which we don't supply at this moment.

• Please pay attention to Max. working pressure on your die. Never go beyond the die's Max. pressure limit

at given temperature, otherwise, the die may be deformed or cracked.- • Here is the example of the pressure comparison table using MTI Refractory Alloy Die under 400ºC

| Gauge Displayed Pressure Value (Mpa) | 2.5 | 5.0 | 7.5 | 10 | | Actual Force Applied on the Hydraulic Cylinder (Ton) | 1.5 | 3 | 4.5 | 6 |

- • The maximum pressure in the press is 6T, the pressure is calculated as below:

- • P = T/(πr^2) x g x 10

- º P: Pressure (MPa) applied on die (ID)

- º T: Force (Ton) applied on the Hydraulic Cylinder

- º g: Standard gravity ≈ 9.8 m/s2

- º π: ~3.14

- º r: Radius (cm) of the ID of die

- º *1 Metric Ton = 1000 kg; 1 MPa ≈ 10 kgf/cm2

|

Compliance

| |

Operation Instructions |  |

Warranty

|

• The pressing machine was quality inspected in the USA, lifetime support is provided- • One year limited standard warranty (Extended warranty is available up to 5 years at the extra cost

|