Configuration

|

• Stainless Steel Chamber - Suitable for Controlled Inert Gas or Vacuum Condition- • Sintering Press Unit

- • Sintering DC Pulse Generator

- • Vacuum Unit

- • Sintering Control Unit

|

| Power | 20 KVA |

| Input Voltage | AC220V 50/60 Hz Three Phases |

| Output Current | DC 0 - 1500 A (Digital Controlled) |

| Output Voltage | DC 0 - 10 V (Digital Control) |

Pulse Frequency |

• 5 - 255 ms Adjustable- • 2 - 1000 Hz adjustable

|

Working Temperature |

• 200ºC - 1200ºC with K-type thermal couple - • 200ºC - 1600ºC with B-type thermal couple

- • Two types of thermal couple are included

|

Temperature controller

|

• Precision Eurotherm temperature controller is built in- • Overshoting temperature is less than 5ºC at the feast heating rate

- • Temperature accuracy : < 0.1ºC

|

Hydraulic Presss

|

• Manual operated hydraulic press to apply pressure.- • Max pressure: 20 T

- • Digital Pressure guage is built in with over-pressure alarm.

|

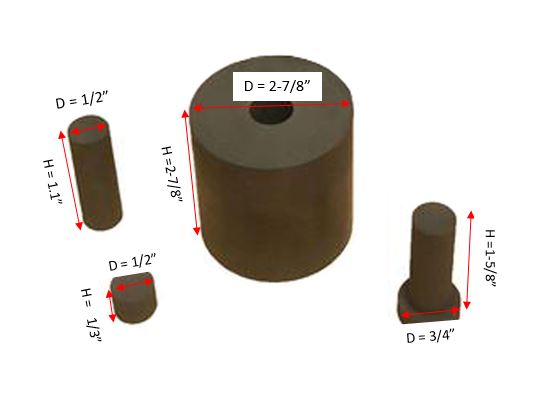

Sintering Die Set Dimension

|

• OD. 85- 100 mm diameter made of HIP graphite in Japan- • ID: 20 mm - 50 mm

- • Sintered Sample size : 20 - 50 mm depended on sintering temperature.

- • Made of high purity graphite by HIP processing, Max. Pressure for the die is 50 MPa, and Max.

Load from the hydraulic press is dependent on die 's ID - º 0.5"ID Max. 0.5T

- º 1.0 ID: Max. 3T

|

| Sintering Stroke | 100 mm |

Vacuum Chamber |

• Vertical vacuum Chamber- • Inner Double Layers Stainless Steel Reflectors

- • Rotary Pump included

|

Max Vacuum Level

(Room Temperature) |

• 10 Pa (7.5 x 10^-2 torr) with the mechanical pump- • One double stage mechanical pump is included

- • 1 Pa ( 10x10-4 torr ) with optional turbo pump ( click picture below right to order )

|

| Pressure Control System | PLC |

| Pressure Stability | ≤±0.1MPa |

| Pressure Rising Rate | ≤2Pa/hr |

Max Heating Rate |

• 300ºC/Minute working temperature betweem 1200 - 1600 ºC- • Note: 50ºC/minute when working at low temperature range 200 - 800ºC

|

| Safety Devices | Emergency Stop System and Warning Alarm System |

Water Cooling |

58L/minute recirculating water chiller is included fro cooling pushing head

|

Standard Accessories |

• SPS Sintering Graphite Die Set- • Graphite Spacer

- • K & B typeThermal Couples

- • O-rings

- • Clamping Tool

|

Dimension |

• Power Supply :760 L X 460 W X 1820 H, mm - • Furnace: 970 L X 720 W X 1400 H, mm

|

| Compliance | |

Warranty: |

• One year limited warranty- • Free training in MTI location is provided before shipping

|

Operational Instruction |

- • The demo video will be available soon

|