Furnace Structure

|

• Double layer steel casing- • High purity fibrous alumina insulation for Max. energy saving.

- • Aluminum heat sink on processing tube to ensure pressure flange and fitting < 60°C

- • Splittable cover for changing tube at easy

|

| Power | 1.5KW |

| Voltage | AC 208 - 240V Single Phase, 50/60 Hz |

| Max. Temperature | 1100°C |

| Max. Heating Rate | <= 10°C/min |

Pressure Vessel

|

• Made of Special Ni-based Superalloy: ( Waspaloy or equivalent )- • Vessel size: 30 mm O.D x 12 mm I.D. x 580 mm Length

- • 1/4NPS female fitting are installed on both end of flanges

- • Ni-based superalloy tube vessel (30mm O.D x 12 mm I.D x 580 mm L)

- • Attention: Processing Tube is a consumable part, you can click the picture below to order replacement or a

spare one. - • Warning: Never put sample inside tube directly without crucible or isolated foil to avoid sample react with

tube alloy.

|

Working Pressure vs

temperature

|

| Maximum pressure inside the tube | Heating temperature | | Max. 2900 PSI (20 Mpa) | 800°C | | Max. 1740 PSI (12Mpa) | 900°C | | Max. 870 PSI (6 Mpa) | 1000°C | | Max. 580 PSI (4 Mpa) | 1100°C |

• Warning: - • Please set up pressure alarm point in digital pressure display before operation

- • Must install a pressure regulator on gas cylinder to increase pressure gradually.

- • Service life depends on the maximum operation temperature and sample used. The high-pressure vessel

is a consumable part, please order replacement once observed deformation.

|

Compatible Gas and

crucible

|

• O2 and inert gasses such as N2, Ar and He- • Note:

|

| Heating Zone length | 200 mm ( single zone ) |

| Temperature Uniformity | +/-1°C within 50mm and +/-2°C in 70mm

|

Temperature control

|

• Precison temperature controller with 30 segments programmable and PID autotune- • LED digital display with the protection of over temperature and the thermal couple broken.

- • Temperature accuracy: +/- 1°C

- • K-type thermal couple built-in

|

Pressure Monitoring and

Relief

|

• Pressure transducer is installed on the right flange and connected to the digital pressure monitor which

allows you set the higher pressure limit.- • One high-pressure solenoid valve is installed on the left flange and controlled by pressure monitor.

- • Max. pressure can be set on pressure monitor. Once Max.pressure inside vessel is reached, gas will be

released automatically. - • Note: Max.pressure of the standard solenoid valve is 150 bar(2165 psi/ 15MPA). If you need

pressure > 150bar at a lower temperature, the manual valve which located beneath the solenoid

valve shall be shut off.

|

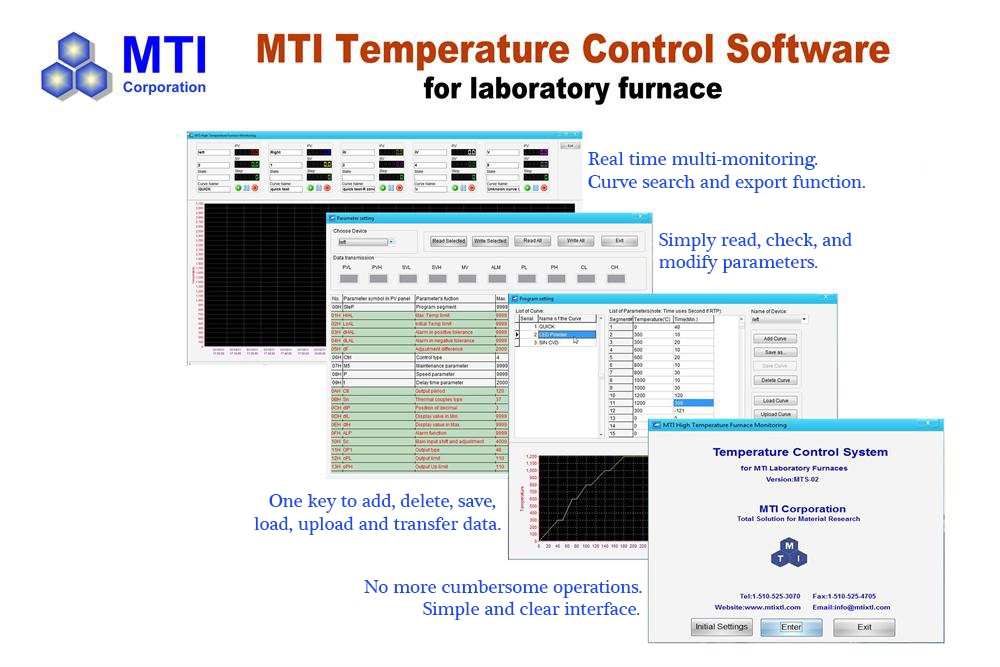

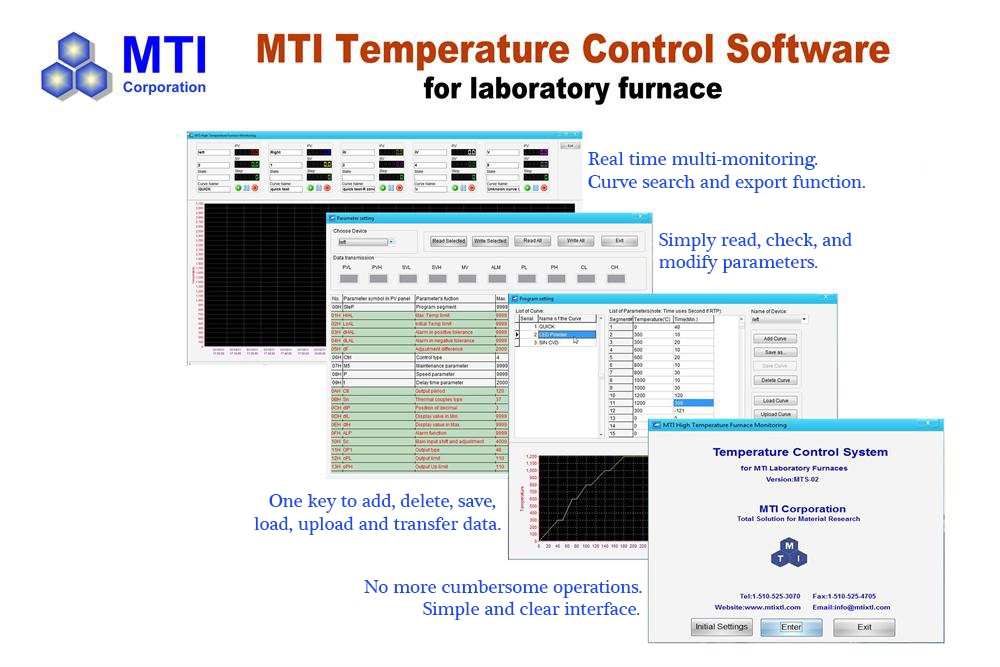

PC Control

|

• A brand new laptop with pre-installed & tested software is included for immediate use(Since 9/10/15).- • An MTS-02 control software is included for controlling and displaying temperature and pressure by PC

at a remote location. - • Please don't try to buy furnace without the computer because liability issues.

|

Pressure Transducer

|

• The pressure transducer is installed on the right flange. The pressure will be displayed in the

pressure monitor on the front panel of the furnace. Pressure measurement ranges up to 250 bars.- • The alarm system is built in the pressure meter which allows the user to set up the high limit point

of pressure. When the measuring pressure exceeds limit point, the alarm will be activated and

open the solenoid pressure relief valve

|

Pressure Fitting

|

• Two flanges with female 1/4" NPT fittings to connect high-pressure tube- • One Aluminum heat radiators are installed in front of flange to keep flange below 100C

- • One high-pressure valve is installed with flanges

- • One Pressure meter installed to one of valve

- • Two high-pressure copper gaskets are included for immediate use. You may click picture below to order

extra Cu gaskets - • Optional torque wrench is available here to avoid overtightening the flange bolts

|

| Heating Element | Fe-Cr-Al Alloy doped by Mo |

Dimension

|

340mm×300mm×400mm ( W x L x H) 340mm×300mm×400mm ( W x L x H)

|

| Net Weight | About 78lb |

| Warranty | One year limited warranty (Consumable parts such as o-rings and heating elements are not covered by the warranty, please order the replacement at related products below.) |

Laptop, software & WiFi Control(Optional) | |

Compliance |

• CE Certified- • All electric components ( >24V) are UL / MET / CSA certified

- • The furnace is ready to pass TUV(UL61010) or CSA certification at extra cost.

( please click marks below to learn details )

|

Operation Instructions |

|

| Shipping package Dimension | 45x45x35 inch |

| Shipping weight | 100lbs |

Application Notes | |

Safety Notes |

• Ni-based Superalloy: ( Waspaloy or equivalent is a reliable processing tube which can be used

under high temperature and high pressure. It has excellent ductility and tensile property so only creep

deformation happens under overpressure destruction test and following by a crack formed (usually at

the hot zone at the center of the tube) to release the pressure. Brittle fracture won’t happen in the

overpressure destruction test which means no tube explosion will happen under the overpressure

of inert gas or safe gas or under other accidents causing overpressure of inert gas or safe gas.

The pics show the Ni-based Superalloy: ( Waspaloy or equivalent ) processing tube under

overpressure test- • Attention: for the use of flammable, toxic or corrosive gasses, you must contact MTI

engineering group for the consultation to know all the prerequisites and precautionary

measures. - • Warning: Never put sample inside tube directly without crucible or isolated foil to avoid sample

react with tube alloy.

- • Do not over tightening the flange screws as this may cause permanent damages to the flange or

screws. Please refer to the instructions about proper torque for installing CF flange bolts.We

recommend you use a torque wrench to tighten the screws with the flange.

|

340mm×300mm×400mm ( W x L x H)

340mm×300mm×400mm ( W x L x H)