Working Pressure vs. Working Temperatue |

• Pressure calculation based on safety factor 3 for 6000 hours service life- º 200 Bar max. at ≤800°C

- º 150 Bar max. at ≤900°C

- º 100 Bar max. at ≤1000°C

- º 50 Bar max. at ≤1100°C

|

Working Gases |

• Inert gas and oxygen- • No hydrogen or any flammable gas

|

Heating Temp.

|

• 1100°C max.for < 1hr - • 1000°C for continuous

|

Heating Rate

| ≤10°C/min |

Heating Element

| Fe-Cr-Al Alloy doped by Mo |

Heating Zone

|

• Two heating zones: 200mm + 200mm - • Total heating zone length: 400mm

- • Constant temp. zone: 175 mm ±2°C

|

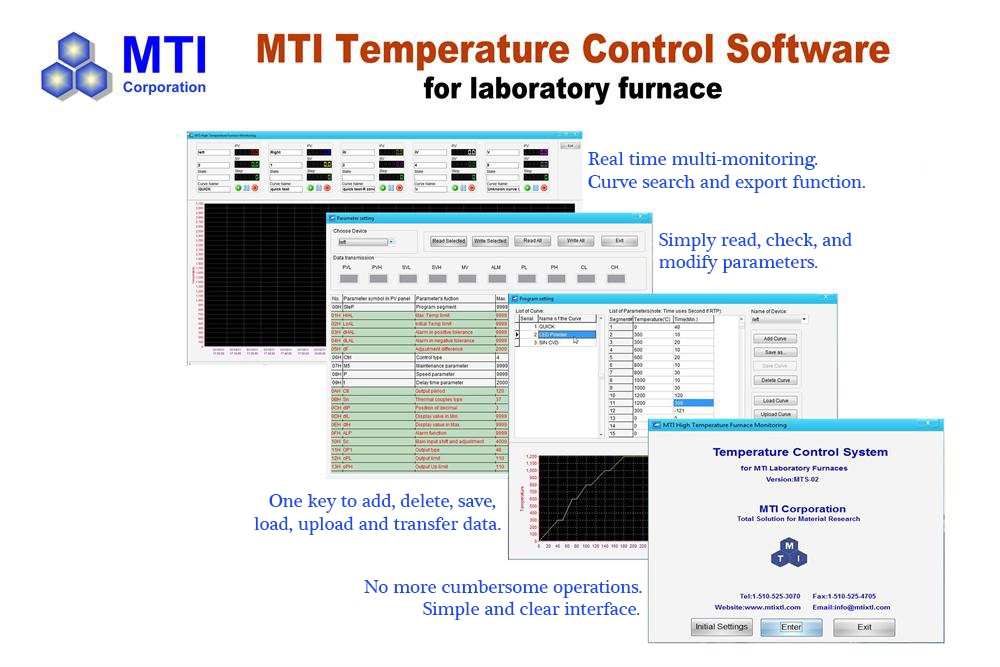

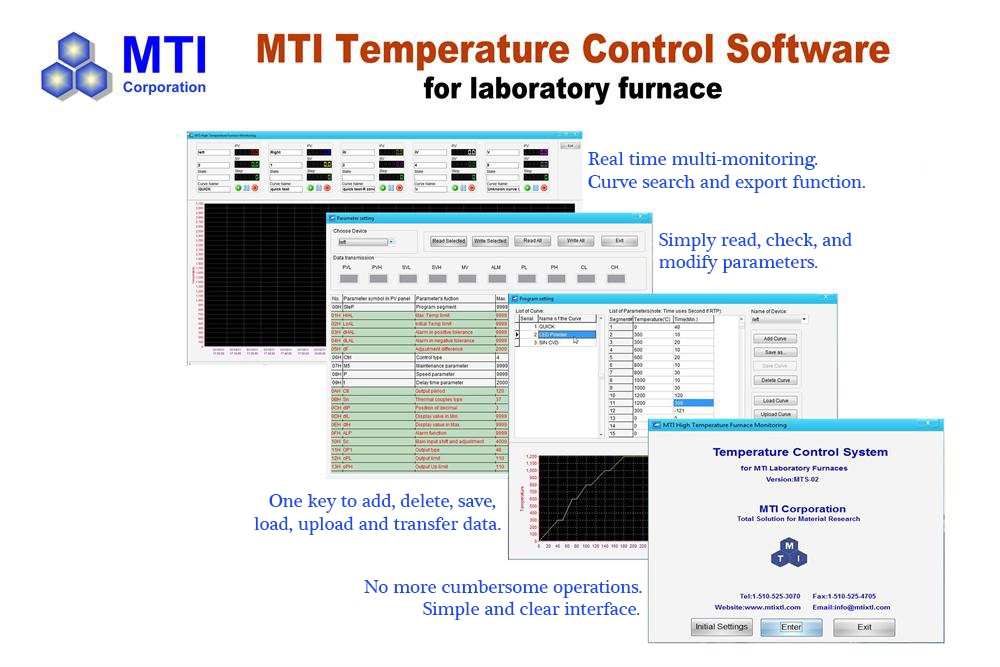

Temperature Control

|

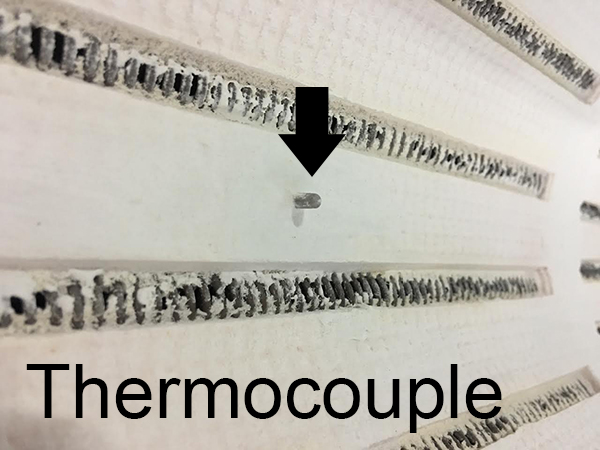

• Three precision digital temperature controller with 30 segments programmable- • PID controlling method with the protection of over-temp. and thermocouple break.

- • Temperature stability: ±1°C

- • PC control software and interface is available at additional cost, please click the bottom left

image to order.

|

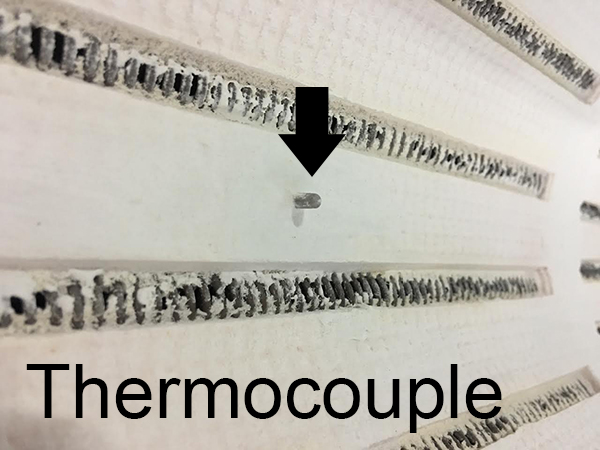

Thermocouple

| |

Positive Pressure Sensor

|

• One digital pressure transducer installed in high-pressure flange- • One pressure controller is included. the release valve will automatically open when the

pressure reaches setting pressure. - • Pressure Measurement Range: 0~15Mpa

|

Process Vessel

| |

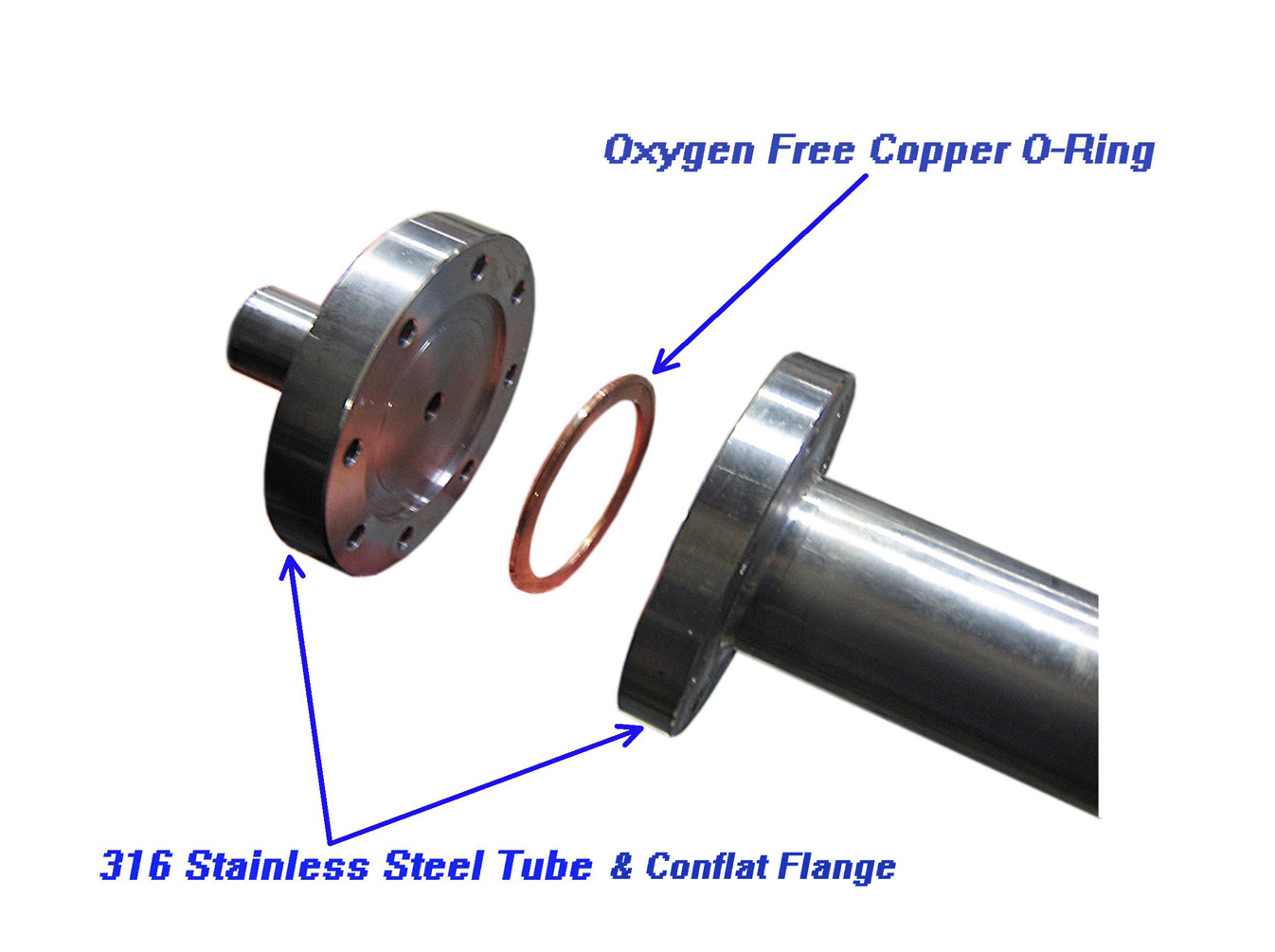

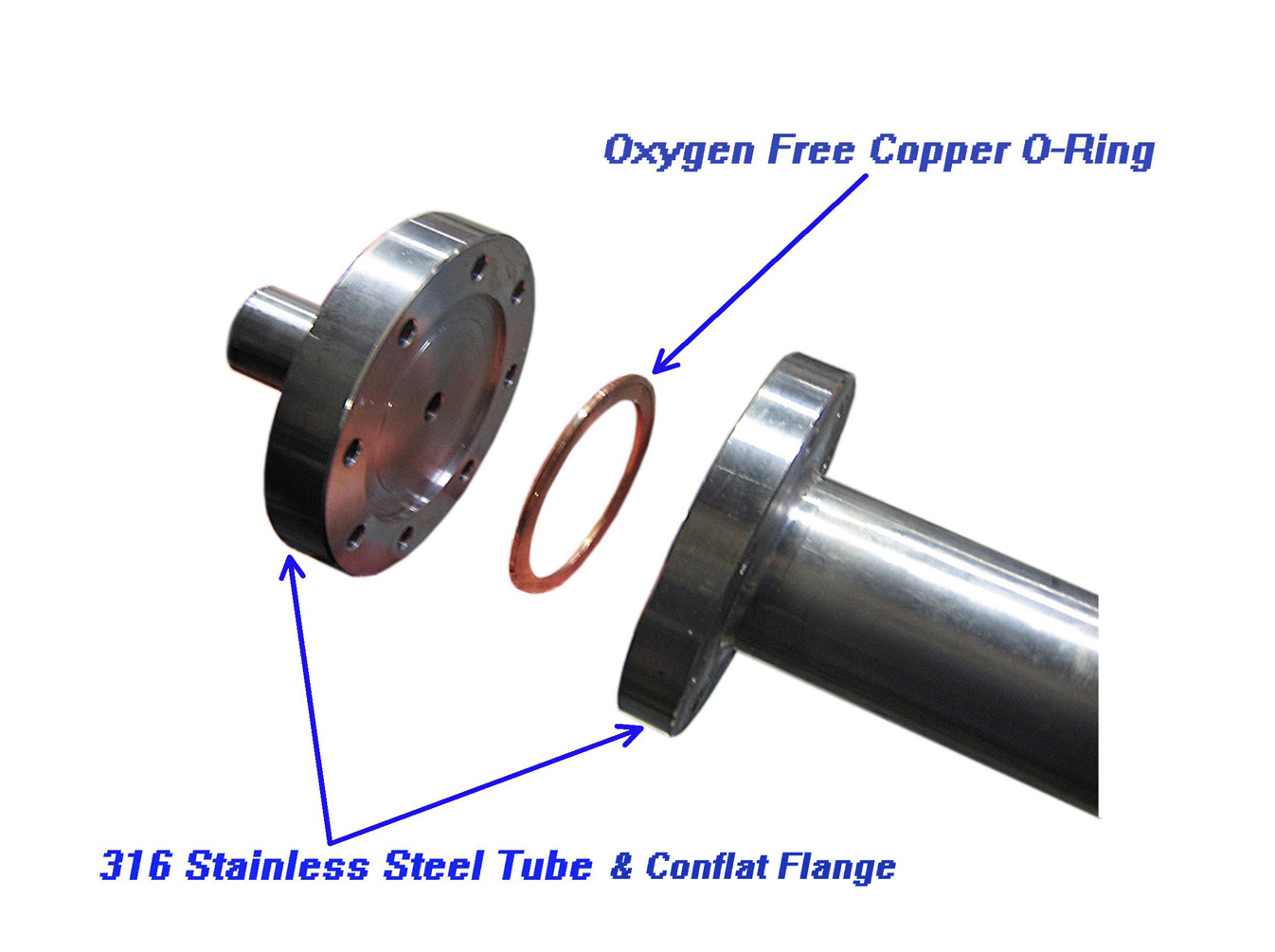

Flange and Fitting |

• A pair of 63mm CF type flanges is included (w/ high-pressure valve and 1/4 tube fitting)- • 2 pcs Copper o-rings are included ( spare copper O-ring is available as consumable.

- • The flange is cooling by forced air via aluminium heat-sink

|

Optional Parts

( with extra cost )

|

• You may order Heavy Duty Rotary Vane Vacuum Pump (7.8 CFM -240 L/m) - EQ-YTP-50 for

experiment under vacuum condition

- • Please consider the Turbomolecular Vacuum Pump Station (up to 1E-7 mbar) - EQ-PV-HVS2

for high vacuum level

- • Gas flow control system is available upon request ( see picture below right )

|

Voltage

| AC 208 - 240V 50/60Hz

|

Power

| 3 KW (20A breaker required) |

Dimension |

900×600×1330 mm 900×600×1330 mm

|

| Operation Instruction |

|

Application Notes |

• The heating temperature must be limited by the certain pressure level due to vessel material

strength. Please refer to the specifications.

- • The pressure is increasing while the temperature is rising during operation. So you need to

calculate the pressure changing towards your target temperature and set a safe value of

pressure during processing.

|

Safety Notes

|

• Ni-based Superalloy ( Waspaloy or equivalent) is a reliable processing tube which can be used

under high temperature and high pressure. It has excellent ductility and tensile property so only

creep deformation happens under overpressure destruction test and following by a crack

formed (usually at the hot zone at the center of the tube) to release the pressure. Brittle

fracture won’t happen in the overpressure destruction test which means no tube explosion will

happen under overpressure

- • The PIC at left shows left Ni-based Superalloy processing tube under overpressure test

- • Attention: For the use with flammable, toxic or corrosive gases, you must contact MTI

engineering group for the consultation to know all the prerequisites and precautionary

measures.

- • Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit

the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas

regulator.

|