Features

|

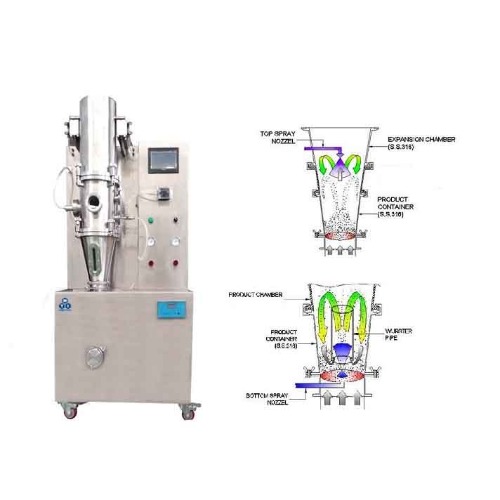

• Contact parts in SS 316 and non-contact parts SS 304- • Single Pot Technology for mixing, granulating, drying & coating

- • Shorter cycle time

- • Highest Degree of Safety

- • Spaying system with the precise flow control peristaltic pump

- • Spraying flow rate controlled by the Peristaltic pump manually

- • Spraying nozzle 0.7 mm size that can be installed in either top or bottom

- • Inlet Air system with filter and electric heater

- • Airflow control by AC Frequency Drive for Exhaust Blower

- • Sight Glass for process visualization

- • Air pressure controls switch for safety

- • All rubber seal made from silicon food grade

- • Easy mechanism to change from process of granulation to coating

|

Power Supply | |

Control Panel |

• 7" Touch Screen Panel to display and set all parameters- • USB port built-in

|

Container Chamber Volume |

• 5 Liter made of SS 304 ( SS 316 is available upon request at the extra cost )- • The one spray gun port on top and one in the bottom

- • Spare spray port on the top of the container is available upon request at the extra cost

|

| Batch Capacity | |

| Drying Temperature | - • 40 - 150⁰C with accuracy +/- 2⁰C

|

Spraying Gan & Nozzle

|

• One spray gun included, which can be installed either on top or bottom according to your

application- • Nozzle hole 0.7mm diameter

- • The spare spray gun is available at the extra cost

- • Optional: Temperature controlled nozzle up to 450ºC is available upon request at the extra cost.

|

Free Air Flow for inlet air ±10% |

• Pressure: 7 bar- • Airflow: 0-150 mᶟ/h

|

Peristaltic pump | |

| Control Panel | |

| Noise Level | |

Supporting Utility Required: |

• Electrical Supply 3 Ph Model with Max. 》 20KW- • Air pressure: 7 Bar

|

| Machine Dimensions (L X W X H) | |

Demo Video

|

Powder Granulation Powder Granulation  Poder Coating Poder Coating

|

| Net Weight | |