Controller |

• 6" LCD color touch screen controller- • Working Voltage: 208-240V AC

- • Max. Power Consumption: 50W

|

Liquid Holder Disk

|

• 5 liquid-holder positions. Carry up to 5 kinds of liquid solutions- • Rotate automatically as programmed for Max. 5 positions and each position can dip max.

20 times. - • Coating up to 5 layers by automatically rotating liquid-holder disk to dip sample from one

solution to another - • Customized program is available upon request at extra cost

|

Beaker |

• Five 150 mL beakers are included for immediate use- • Dimensions: 60mm(Dia) x 60mm(H)

|

Programming |

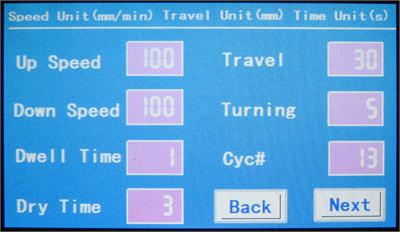

• Travelling Distance: 0-75 mm Adjustable- • Dipping/Pulling Speed: 1-200 mm/min Programmable with accuracy within +/- 0.02%

- • Temperature Range: 50-100°C (+/-1°C accuracy)

- • Dwell Time: 0-999 seconds (in liquid time)

- • Dry Time: 0-999 seconds

- • Dipping Position (turning): 1 - 5 positions (Max. 5 positions)

- • Dipping (cycle): Max. 20 times (dipping in each position)

Note: Each beaker position shares the same programming parameters.

|

Sample Holder

|

Up to 2 samples can be carried sliding up and down through two guide rods |

Oven |

• Working Voltage: 208-240V AC (110V version is available via transformer)- • Max. Power Consumption: 600W

- • Chamber Dimensions: 254mm(L) x 254mm(W) x 280mm(H)

- • Inner Material: Stainless Steel

- • Outside Dimensions: 406mm(L) x 406mm(W) x 610mm(H)

|

Product Dimensions

|

440mm(L) x 460mm(W) x 1040mm(H) 440mm(L) x 460mm(W) x 1040mm(H) |

| Compliance | CE Certified |

| Warranty | One year limited with lifetime support |

Operation Manual & Video |

|

Application Notes |

• In order to get better film coating, the substrate shall be treated by plasma cleaner

(Please click on the first picture below for more information)- • Use ultrasonic processor to disperse nano powder or homogenize solution to get better

coating (Please click on the second picture below for more information) - • Liquid solution is placed in the controlled temperature oven with +/-1°C tolerance from room

temperature to 100°C. Please keep warm at least half hour after the temperature reach the

set point on the digital temperature meter to ensure an equilibrium temperature distribution

in the liquid solution - • Click here to visit our Knowledge Center and learn about dip coating

- • Test the flexibility of the thin film / coated electrode with EQ-MBT-12-LD mandrel bending tester.

|

| Net Weight | 57 kg (125 lbs) |

| Shipping Weight | 82 kg (180 lbs) |

| Shipping Dimensions | 45"(L) x45"(W) x40"(H) |