|

• Double-layer stainless steel structure for maximum vacuum and safety.

• Water cooling front door and air cooling shell • Built-in pressure gauge, vacuum valves, and two gas float meters • Built-in H2 burning control system --- if the controller detects no flame in the burner, the gas

delivery valve will be shut down automatically

|

Inside Chamber Size

|

• Heated chamber: 200x 200x 200 mm (8x8x8 inch), 8 Liter- • Energy-saving 1800 grade fibrous alumina insulation

- • High purity Al2O3 coating

- • Warning: One Al2O3 fibrous door block is included. You must place the door block in the front

the chamber to block heat radiation, otherwise, may damage seal ring at high temperature and

cause hydrogen gas leaking

|

Power | 7.5 KW |

Voltage | AC 208 - 240V single phase (50/ 60 Hz) |

Current | 30 Amp (50 Amp air breaker is required) |

Temperature | Continuous 1600° C

Max. 1650° C(<60min)

|

Heating Rate | 5°C / min |

Temperature Accuracy | +/- 1°C |

Thermocouple | two B type thermocouples (control thermocouple and secondary alarm thermocouple) |

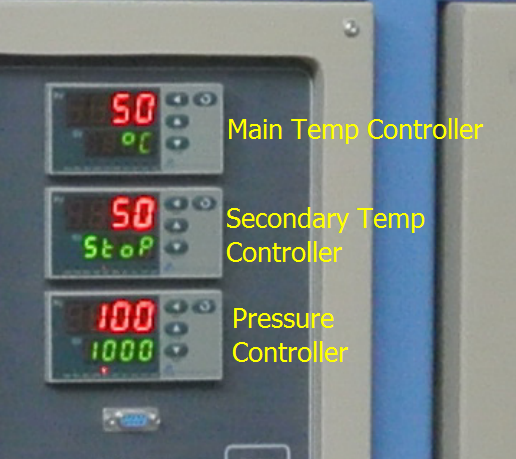

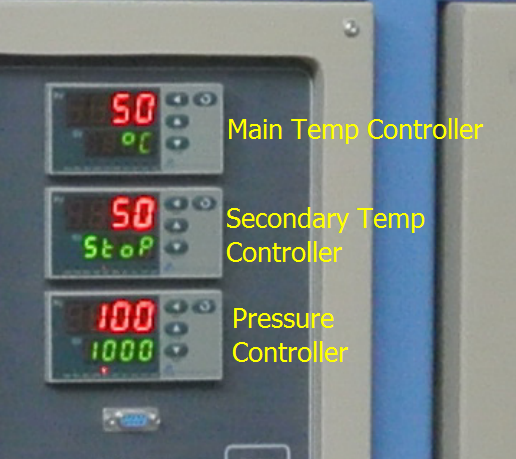

Temperature controller

|

Main Temperature Controller is used for controlling the 30-segment heating program and provides the 1-level temperature alarm protection.

Secondary Temperature Controller reads the temperature from the secondary B type thermocouple, monitors the temperature during all process and provides the 2-level temperature alarm protection.

|

Pressure Control

|

• The pressure sensor and pressure controller are installed. It reads the chamber pressure and

controls the inlet and outlet gas valves respectively according to the pressure limit settings.

- • The pressure control can be used to perform the following functions:

- Purging

- Pressure control

- High and Low-pressure protection

- • The pressure controllable range: -0.06 to 0.03Mpa.

|

Heating Elements

|

• 6 sets of Mo coils heating elements are built-in and replaceable - • The heating element of Mo coil is consumable parts which should be ordered separately if

extra is required. ( order pictured below left to order spare ) - • The heating element can be replaced by MsSi2 to run furnace under oxygen and air up to

1700°C (order picture below right to order spare) - • Warning: Mo heating element cannot be used under air or oxygen at the temperature > 300°C

|

Temperature Control

|

• FA-YD518P-AG temperature controller is included.- • Proportional–integral–derivative control (PID control) and auto-tune function

- • 30 segments programmed with ramping, cooling and dwelling steps

- • Built-in over-temperature alarm and thermocouple failure alarm

- • +/- 1 ºC temperature control accuracy

- • Default DB9 PC communication port

- • MET Certified

|

Temperature controller (optional)

| |

Eurotherm Nanodac Controller (optional)

|

• A single one Eurotherm Nanodac Controller replaces all three original controllers in the furnace

and performs advanced functions of:- High accuracy temperature control

- Secondary temperature monitor and alarm

- Pressure control and alarm

- Data acquisition/analysis and graphical recording

- TCP/IP communications

- Eurotherm software included

- A 15.6-inch screen laptop is included in the package. The Eurotherm software is installed and configurated.

|

Gas Flow Control and Vacuum Valve

|

• Two large flow meters (N2: 0~3.5L/min, H2: 0~3.5L/min) are installed on the front panel of the

furnace.- • One for purging Inert gas prior to introducing H2 gas

- • One for controlling H2 gas flow

- • One heavy-duty vacuum pump ( CE certified ) built-in bottom furnace.

You may choose a UL certified pump at extra cost ( Pls click picture below to see specs)

( CE certified ) ( CE certified )  ( TUV certified ) ( TUV certified )

|

H2 Gas Burning Control System

and Option Hydrogen detector

|

• An ignition device already installed to incinerate flowing gas and detect burner temperature to

ensure H2 burner is in working condition. If H2 does not burn properly, the controller will shut

down the H2 gas delivery valve immediately.- • Warning: You must install a certified Hydrogen detector in operation facility to alarm hydrogen

leaking b accident. If you can not find in a local store, please click the link below to order

hydrogen detector from us at extra cost. - • Option Hydrogen detector to Enhanced safety for MTI Hydrogen Gas Tube Furnace

|

Water Cooling

|

A 58L/min recirculating water chiller is installed for cooling furnace sealing flange.

|

Net Weight | 300Kg |

Overall Dimensions

|

1200mmL×850mmW×1520mmH ( without burner ) and 2020 H ( with burner ) 1200mmL×850mmW×1520mmH ( without burner ) and 2020 H ( with burner )

|

Shipping Weight & Dimensions

|

• Two Pallets- • 1375 lbs, 54"x44"x89"

- • 320 lbs, 48"x40"x52"

|

Warranty

|

One year limited warranty with lifetime support. (Consumable parts such as sample plates and heating elements are not covered by the warranty, please order the replacement at related products below.

Attention: A free course of safety operation training at MTI field is required to purchase this furnace. A customer's side training is also available upon request at extra cost. If the users believe that they have sufficient experience and knowledge to handle the furnace in the dangerous or emergent situation, a liability release agreement must be signed at the purchase. MTI Corp. is not responsible for any damages caused by misuse without safety operation training. Any damages caused by the corrosive and acidic gases are not under the coverage of the MTI One Year Limited Warranty.

|

Compliance

|

• CE Certified- • All electric components ( >24V) are UL / MET / CSA certified

- • NRTL or CSA certification is available upon request at extra cost.

( please click mark below to learn details )

-

|

Application Notes

|

• Please EXERCISE EXTREME CAUTION. H2 gas is highly flammable and explosive. H2 ignites

at a temperature of 400°C, an explosion could occur when the hydrogen content reaches

4.0%-74. 2% in the air, please strictly follow the rules below to for safe operation.- • Inert gas MUST be used to purge the furnace chamber to eliminate all the air before introducing

the H2 gas. - • The pressure inside the chamber should ALWAYS be controlled at around 0.01Mpa above

during the entire heating process, otherwise, the oxygen in the air may backflow into the

furnace chamber and cause the explosion in the worst-case scenario. - • Pressure over 0.02Mpa (Relative Pressure) is strictly prohibited.

- • ALWAYS place the furnace in a room with a fume hood and a hydrogen detector installed.

- • Good ventilation is necessary for the room in which place the furnace

- • Exhausting Hydrogen gas in the room is forbidden.

- • For preserving the longevity of the furnace components, we recommend the heating rate not to

exceed 10 °C /min. - • Small cracks may appear on the surface of the refractory ceramics over extended use.

This is a normal occurrence and the cracks may be repaired with alumina coating. - • Please click here to learn how to DIY gas purging system.

- • The refractory block must be inserted before the closing door.

- • Please Click Underline to learn "Max. Working Temperature of Heating Elements of Tungsten,

Tantalum, Molybdenum Under Various Processing Gases". - • Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit

the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas

regulator.

|

Demo Video and

Operation Instructions

| |