| Series | KSL-1800X-G1 | KSL-1800X-G2 |

Voltage & Power |

• AC 208 V Three Phases 50/60 Hz- • Maximum Power Consumption: 57 kW

|

• AC 460V three Phases 50/60 Hz- • Maximum Power Consumption: 110 kW

|

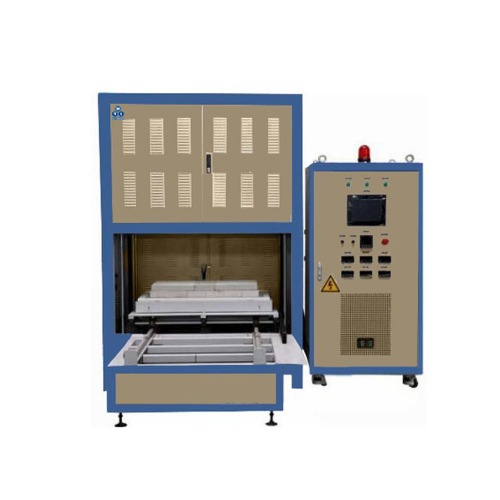

| Heating Chamber Size | - • 860 L ×340 W ×300 H (mm )

| - • 1180L × 340W × 400 H (mm)

|

Dimension & Weight |

• Main Furnace: 1500 mm x 1080 mm x

220 mm- • Temperature Controller: 800 mm x 800

mm x 1770 mm - • Net Weight: 2300 kg

|

• Main Furnace: 1900 mm x 1200 mm x 2500 mm- • Temperature Controller: 800 mm x 800 mm x

1770 mm - • Net Weight: 2600 kg

|

| Standard Working Temperature | |

| Maximum Working Temperature | |

Heating Rate |

• 0 - 5° C / min- • Suggestion =< 2° C

|

| Temperature Accuracy | |

Temperature Uniformity |

• +/- 5°C over 120 mm (5") @ 1700°C- • +/- 2°C over 80 mm (3") @ 1700°C

|

Heating Elements |

• 4 sides heating chamber- • Grade MoSi2

- • 24 pieces in total

|

| Thermal Couple | |

| Sample Loading | - • From bottom to the top heating chamber

|

Temperature Controller

|

• Eurotherm 3500 Series Programmable Temperature Controller.- • 10 program, 50 segments programmed with ramping, cooling and dwelling steps

- • Temperature Accuracy: ± 0.1ºC

- • Using the PC software, recipes can be created to change the operating parameters of the controller

by selecting a new recipe via the HMI. This is very helpful where multiple products that require

different temperature profiles can be processed using the same controller

|

Laptop & software (Optional) |

• Brand new laptop with Microsoft Window 10 and Microsoft Office 2013 (30 days free trial) for

immediate use.- • Labview Based Temperature Control System enables the user to edit temperature profile and

manage heat-treatment recipe for MTI furnaces. - • Note: Due to the complexity of the controller operation, we strongly suggest customers to purchase

this PC control kit along with the furnace and our engineers will have the software & hardware

pre-installed. Please note that this PC control kit is not for sale individually

|

Power Cable & Plug |

• 10 feet length 10-3 AWG heavy duty UL approved power cable is included- • Extra length cable can be ordered by click picture below

- • The plug is not included. You can order from your local hardware store according to female plug

in your lab, or order from link below (30A plug)

(click here to order plugs from us) (click here to order plugs from us)

|

Warranty |

• One year limited warranty with life time support. (Consumable parts such as sample plates and

heating elements are not covered by the warranty, please order the replacement at related

products below.)- • ATTENTION: Any damages caused by the use of corrosive and acidic gases are not

under the coverage of MTI One Year Limited Warranty.

|

Compliance |

• CE Certified- • All electric components ( >24V) are UL / MET / CSA certified

- • The furnace is ready to pass TUV(UL61010) or CSA certification at extra cost.

( please click marks below to learn details )

|

Application Notes |

• For preserving the longevity of the furnace components, we recommend the heating rate not to

exceed 2 °C /min.- • The cooling rate shall also not exceed 2 °C /min.

- • This furnace lacks vacuum sealing, toxic or explosive gases are not recommended for use with

this furnace without necessary safety controls and supervision. - • Small cracks may appear on the surface of the refractory ceramics over extended use. This is a

normal occurrence and the cracks may be repaired with alumina coating. - • Please click here to learn how to DIY gas purging system.

- • The refractory block must be inserted before closing door.

|

| Operation Instructions | |