Furnace Structure

|

● Double-layer steel structure.- ● High purity Al2O3 fibrous insulation with Max. energy saving

- ● High purity alumina coating on refractory ceramics for longer service life.

|

Power | 1.2 KW |

Voltage

|

110VAC or 220VAC

(Please select the voltage in the options bar)

|

Max. Temperature | 1200°C (<1 hour) |

Continuous Temperature | 1100°C ( continuous) |

Max. Heating Rate | <= 10 °C/min |

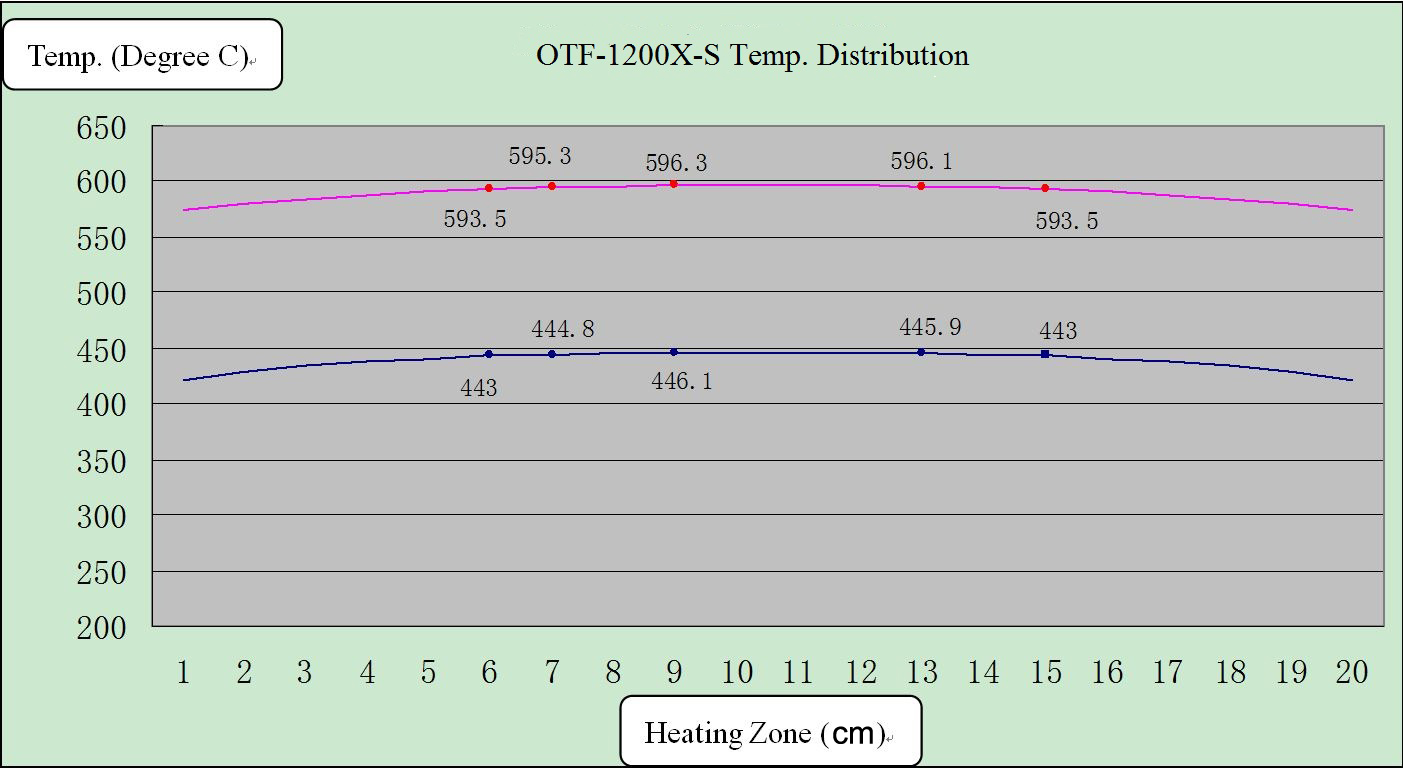

Heating Zone Length

|

8" (200mm), single zone. The following picture shows the temp. distribution across the heating zone

|

Constant Temp. Zone | 2.3" (60mm) (+/-1°C) @ 1000 °C |

Temperature Controller

|

● Proportional–integral–derivative control (PID control) and auto-tune function

- ● Built-in Over Temperature and Thermocouple Failure Protection

- ● 30 segments programmed with ramping, cooling, and dwelling steps

- ● Default DB9 PC communication port

- ● Temperature accuracy: +/- 1°C

|

Advanced Temp. Controller

(Optional)

|

● You may upgrade the temperature controller to the Eurotherm 32H8 with +/- 0.1ºC accuracy.- ● This package includes a Eurotherm 32H8 programmer, a communication cable (RS485 - USB),

and a software CD. Click the pic left to view the full specs

|

Heating Elements | Fe-Cr-Al Alloy doped by Mo |

Tube Size Options

| |

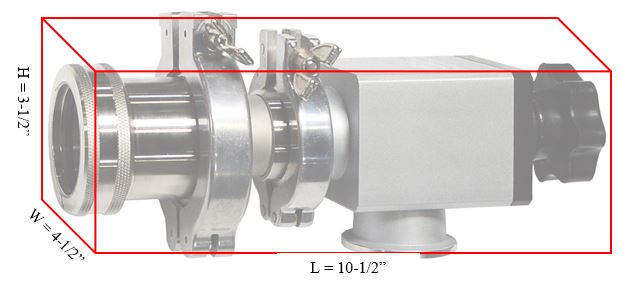

Vacuum Flanges |

● 2" and 2.36" tube flange with 1/4'' Bard fittings, 1/4'' tube feedthrough port (for 1/4" O.D thermocouple

insert) and a KF25 vacuum port(click bottom left picture to see details )- ● 1" flange has no thermocouple insert ( click the bottom right picture to see details )

|

Vacuum Level | 10-2torr (by the mechanical pump) |

Fitting Ports

&

Optional Parts |

● You may need a vacuum valve at the vacuum port ( click picture left to order )- ● You may consider ordering quick connecting flange at extra cost.

- ● You may click the pictures in below to order the furnace with a vacuum pump and a temperature

calibration kit.

-

|

Pressure Measurement / Monitoring

|

● Standard mechanical vacuum gauge measures within a pressure range of -0.1 to 0.15Mpa is included.- ● OPTIONAL (EXTRA COST WILL BE APPLIED): A gas-type independent (above 10mbar) digital vacuum gauge with a wide range between 3.8x10-5 to 1125 Torr. Aside from greater measurement precision, this gauge reduces the risks of chamber explosions caused by the incorrect reading of gas pressures due to gas-type dependency.

|

Dimensions

|

● With lid closed: 340mm(L) × 300mm(W) × 400mm(H)

● With lid open: 340mm(L) × 300mm(W) × 560mm(H)

|

Net Weight | 35 Kg |

Shipping Package Size | 40''(L) x 30''(W) x 35''(H) |

Shipping Weight | 110 lbs |

Warranty

|

One-year limited warranty with lifetime support (Consumable parts such as processing tubes and o-rings are not covered by the warranty, please order replacements at related products below.)

|

Laptop, software & WiFi Control (Optional)

|

● Brand new laptop with Microsoft Windows 10 and Microsoft Office 2013 (30 days free trial)- ● Labview Based Temperature Control System (EQ-MTS01) enables users to edit temperature

profiles, manage heat-treatment recipes, record, and plot data for MTI furnaces. - ● A wireless remote control provides up to 300 meters of operating range.

- ● The above features are available upon request at an extra cost (up to $1,000).

|

Compliance

|

● CE Certified- ● NRTL or CSA certification is available upon request at the extra cost.

|

Application Notes & Warning

|

● Tube furnaces with quartz tubes are designed for use under vacuum and low pressure < 0.2 bars. - ● Vacuum pressures may only be safely used up to 1000°CThe flow rate for gasses should be limited

to<200 SCCM (or 200ml/min) for reducing thermal shocks to the tube - ● Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the

pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator. - ● How to set up a ceramic tube and vacuum flange for MTI tube furnaces.

- ● For safety, you may consider putting the small tube furnace inside a fume hood. ( click picture left to see )

|

Operation Demo Vidoe |

|