Furnace Structure

|

• Double-layer steel structure with air cooling.- • High purity Al2O3 fibrous insulation with Max. energy saving.

- • Split cover for easy tube replacement.

- • Adopts 1" or 2" O.D processing tubes.

|

Power | 1.2 KW |

Voltage | 110VAC ( Single Phase 220VAC can be selected in options bar) |

Max. Temperature | 1250°C (<1 hour) |

Continuous Temperature

vs

Processing Tube

|

• 1200°C ( continuous) with Mullite tube 1-2 " dia- • 1100°C ( continuous) with Quartz tube 1- 2" dia

- • Please click Pic below to choose processing tube ( Length > 450 mm )

Quartz tube Quartz tube  Mullite tube Mullite tube

Vacuum Flange Vacuum Flange

|

Max. Heating Rate | <= 10 °C/min |

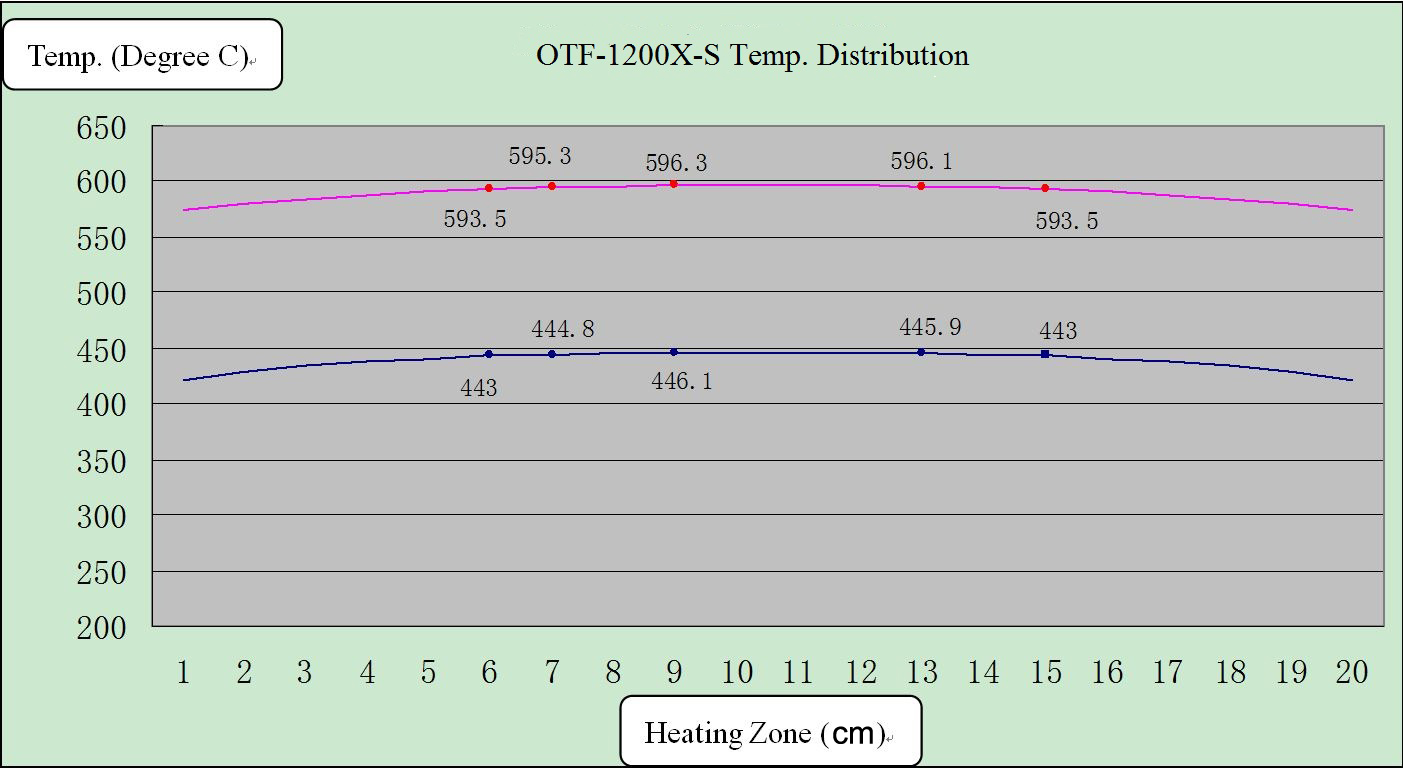

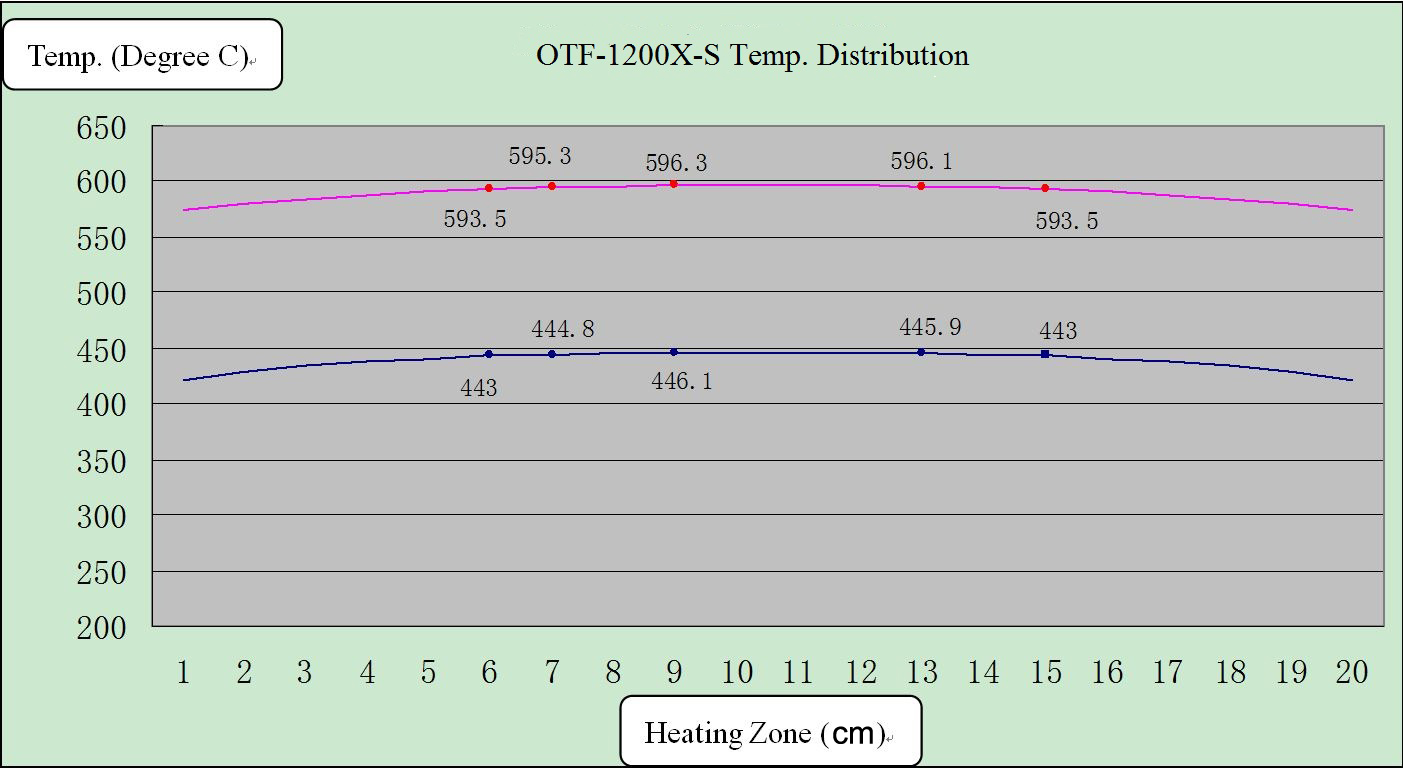

Heating Zone length

|

8" (200mm), single zone. The following picture shows the temp. distribution across the heating zone, please click to enlarge.

|

Constant Temp. Zone

| 2.3" (60mm) (+/-1°C) @ 900 °C |

Temperature Controller

| |

Temperature Accuracy | +/- 1°C |

Heating Element | Fe-Cr-Al Alloy doped by Mo |

Dimensions

|

• With lid closed: 340mm×300mm×400mm ( W x L x H)

• With lid open: 340mm×300mm×560mm ( W x L x H)

|

Net Weight | 18 Kg |

Shipping Package Size | 40 x 28 x 33 inches (W x L xH) |

Shipping Weight | 100 lbs |

Warranty | One year limited warranty with lifetime support |

Laptop, software & WiFi Control

(Optional)

| |

Compliance |

• CE Certified and UL 6010 standard ready- • UL / MET / CSA Certification is available upon request, additional charges will apply

|

Application Notes & Warning

|

• Tube furnaces with quartz tubes are designed for using under vacuum and low pressure < 0.2

bars / 3 psi / 0.02 MPa. Vacuum pressures may only be safely used up to 1000°CThe flow rate

for gases should be limited to<200 SCCM (or 200ml/min) for reducing thermal shocks to the tube- • Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the

pressure to below 3 PSI for safe operation.

Click here to learn the installation of a gas regulator. - • How to set up a ceramic tube and vacuum flange for MTI tube furnaces.

- • For safety, you may consider putting the small tube furnace inside a fume hood.

( click picture left to see )

|

| Operation Instructions |  |