Power | • 220 VAC, single phase, 50/60 Hz. • Maximum power: 3 kW (20A breaker required) • A power cord is included without the plug

|

| Working Temperature | |

| Max. Heating Rate | |

Tube Furnace |    |

Temperature Control |

• Built-in PID auto-tune function with overheating & broken thermocouple protection

• Over-temperature protection and alarm allows for operation without attendant(s) • Precise temperature control with less than 1 ℃ temperature fluctuation during dwelling. • Optional: The furnace may be remotely controlled by a PC by installing a communication module in the controller. Please order an MTS-02 control module at an extra cost If you order the PC control module together with the furnace, we will install and test it before shipping. We recommend you to order a software-ready laptop from us

|

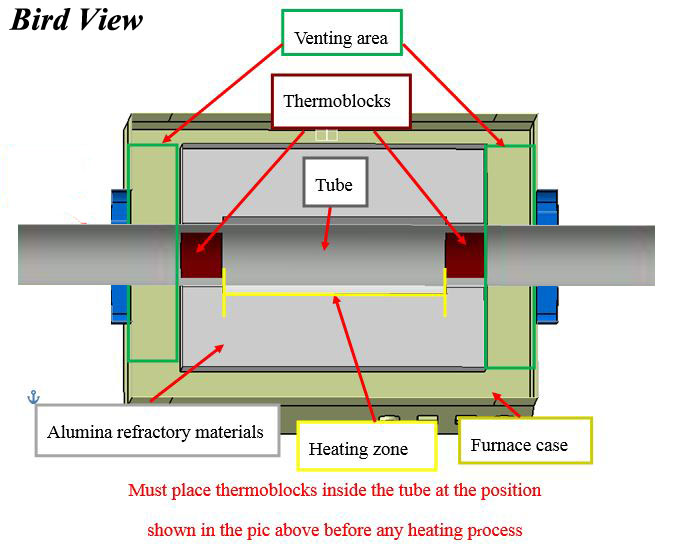

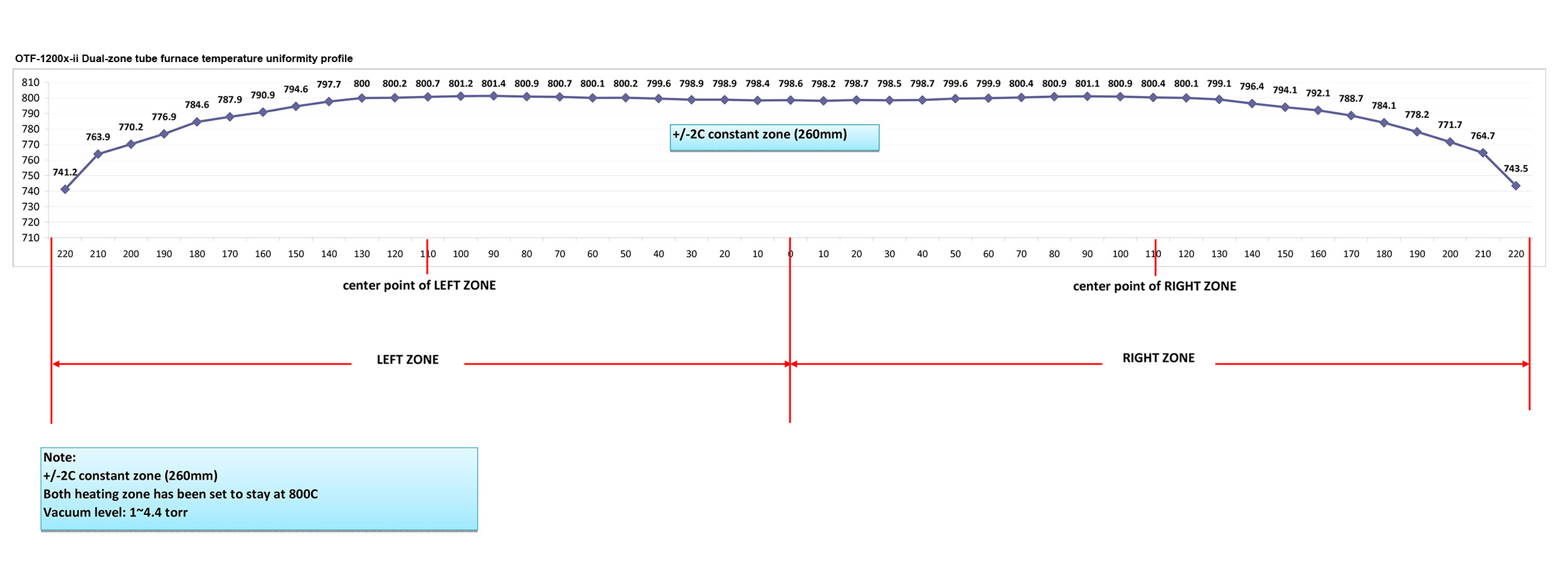

Temperature Uniformity

|

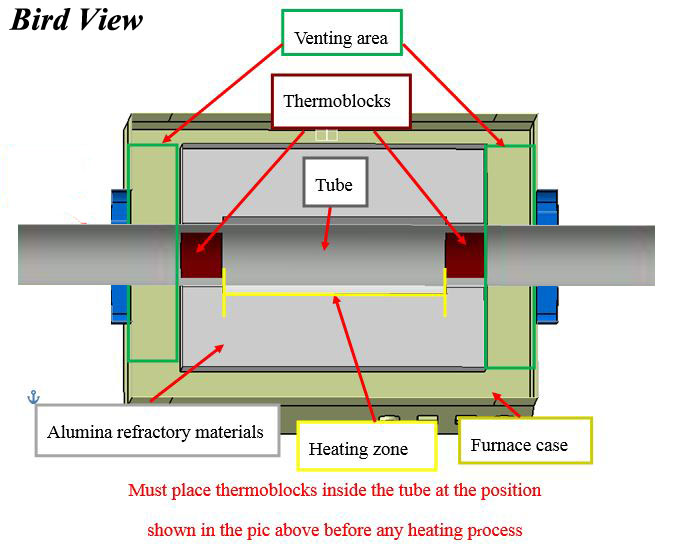

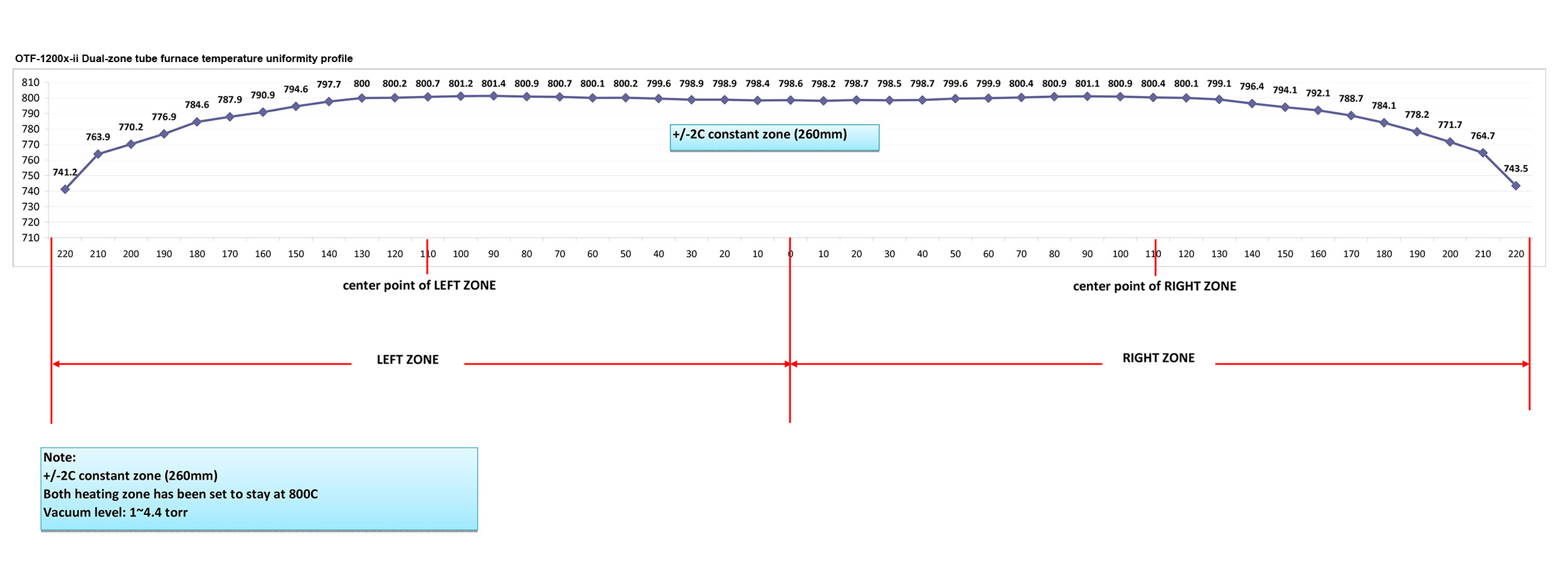

• 150mm (+/-1°C) heating area with best temperature uniformity for each heating zone.

• A longer area of temperature uniformity (~ 250mm) can be created by setting both zones at

the same temperature • Please click the picture below to view the detail of temperature uniformity profile at 800°C

|

Flanges & Fittings

(Flange size will be matched with the tube size. Please select in the option bar)

|

• Flanges with 1/4” tube fittings and mechanical valves are included on the both sides.

• Flange fixtures and tube covers are installed to provide additional safety protection in case of

hydrogen hazards. It is easy to open one side of flange for quick sample loading • Flange with additional 1/4" themocouple feedthrough is available at an extra cost for in-situ

temperature calibration and measurements. • Flange with KF25 port is also available at an extra cost for quick connection with a vacuum

pump. • Water-cooled flanges at an extra cost are required if thermal blocks are not inserted.

|

Gas Delivery |

• The tube furnace comes with a pressure gauge and 0 - 1000 ml/min floating flow meter to

precisely control the overall pressure and flow rate in the quartz tube.

• Two separated gas delivery lines for hydrogen and inert gases. • The inert gas line comes with a mechanical needle valve. • The hydrogen line comes with a mechanical needle valve and a solenoid valve controlled by

the hydrogen gas detector.

|

Hydrogen Detector System

(included) (included) |

• One Honeywell UL Approved Sensepoint Gas Detector is integrated into the system.

• Working Temperature Range: 40ºF to +149ºF (-40ºC to +65ºC) • Alarm Set Point at 10% (10% LEL). The hydrogen gas delivery line and heating elements will

be shut down automatically once the alarm is activated.

|

Hydrogen Torch |

|

| Net Weight | |

| Shipping weight | |

Warranty | • One year limited warranty with lifetime support.

The quartz tube as a consumable part is not covered by warranty. • Attention: A free course of safety operation training at MTI field is required to purchase this

furnace. A customer's side training is also available upon request at extra cost. If the users

believe that they have sufficient experience and knowledge to handle the furnace in a

dangerous situation or emergency, a liability release agreement must be signed at the

purchase. MTI Corporation is not responsible for any damages caused by misuse without the

safety operation training. Any damages caused by the corrosive and acidic gases are not

under the coverage of the MTI One Year Limited Warranty.

|

Compliance |

|

Warning

Click here to learn the installation of a gas regulator

|

• Tube furnaces with alumina tubes are designed for using under vacuum < 0.12 atm

(absolute pressure) and low positive pressure

• The flow rate of gases should be < 200 SCCM (or 200 ml/min) for reducing thermal shocks

to the tube • Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit

the pressure below 3 PSI for safe operation. Click here to learn the installation of a gas

regulator.

Please note that the regulator for hydrogen gas is different from that for inert gas. • Quartz tubes may only be safely used up to 1000° under vacuum condition.

|