| Power | - Glovebox: N/A

- Pressure Controller: 110 - 220 VAC, 50/60 Hz

|

Glove Box Chamber

| - Case Material: Made of 11 gauge (3mm thickness) 304 stainless steel sheet with the support frame, which provides the heavy-duty structure for vacuum.

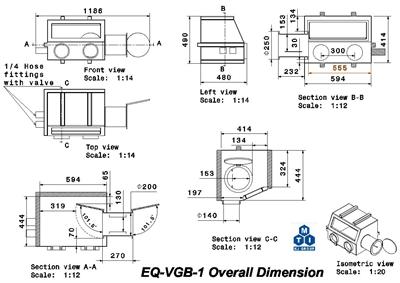

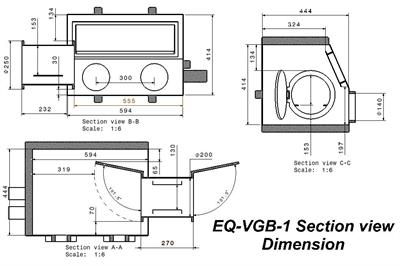

- Dimensions: 555 (L) × 444 (W) × 414 (H)

- Window: 480 (L) × 125 mm (H)

- Max. Positive Pressure: 810 Torr (1.1 atm)

- Note: Gloves cannot work if pressure is higher than 810 Torr

- Max. Vacuum Level: 1.59E-2 Torr

- ~50 Torr after 5 min pumping

- ~6E-2 Torr after 4 hr pumping.

- Note: Stainless Steel case may deform at a higher vacuum level

- Leakage Rate in GloveBox: < 6 Torr/hour

|

| Pressure Controller | - EQ-KJT-2V Automatic Pressure Controller is integrated with the glovebox to maintain constant inert gas pressure inside the main chamber.

- One pressure transducer and two solenoid valves are pre-installed in the back of the Main Chamber.

- Pressure Range: 90 - 320 kPa with 0.5% accuracy.

- Pressure Controller must be power OFF when vacuum the Main Chamber.

|

| Antechamber | - Dimensions: 200mm(ID) x 220mm(L)

|

| Vacuum gauge and valves | - Two vacuum flanges are included for the glove box to achieve vacuum to remove moisture and oxygen without expensive inert gas purging.

- Do not operate under vacuum. Vacuum is used for purging the chamber before the operation.

- One KF-25 connector is installed on the back for connecting the humidity monitor or other testing equipment.

|

| Power Extension | - One outlet strip (Max power 1500W) with feedthrough is installed in the glove box main chamber.

- Note: 110V power cord was included for immediate use. (For 208~240V power supply, no plug will be included)

|

Gloves

| - One pair of Latex Gloves are included for immediate use.

- Optional: You may order 6'' Butadyl® gloves here because they have:

- Increased stretching, bending ability, and tear strength

- High effectiveness when vaporized hydrogen peroxide (VHP) is present

- High resistance to aromatics, hydrocarbons, solvents, fats, and acids

- High static dissipative qualities

|

Vacuum Pump

(Optional) | - The vacuum pump and fittings are not included. (Please order separately under Personalization)

- Note: A KF25 Vacuum Right-Angle Valve is necessary for connecting to a vacuum pump, please order it accordingly.

|

| Product Dimensions | 1186mm(L) x 480mm(W) x 490mm(H) |

| Warranty | - One year limited warranty with lifetime support

- Rusting and damage due to improper storage condition or maintenance is not covered by warranty

- Gloves are consumable items and are not covered under warranty

|

| Operation Video |   |

| Application Notes | - Corrosive liquid (such as LiPF6 electrolyte) must be remain sealed in a container inside the glove box. Otherwise, liquid-vapor may condense and corrode the steel chamber and purification pipeline.

- By closing the vacuum flange, the glove box can be vacuumed by a mechanical pump up to 0.5 torrs before filling inert gas. The moisture can be reduced below 50 ppm by vacuuming the glove box

- After refilling the glove box with high purity Argon gas (5N purity), the glove box moisture can be kept below 180 ppm and oxygen below 200 ppm. In this way, you can save 1-2 tank of inert gas from purging at each operation

- Please call or email us to get the price and lead time for multi-pins feedthrough on the glove box if you need to measure the sample inside the chamber.

16 pins electrical feed through outside the glove box (4 pins per one feed through) | 16 pins electrical feed through inside the glove box (4 pins per one feed through) | | |

- You may choose the device below to monitor gas humidity and oxygen content inside the glove box.

- Warning: This glove box is not suitable for Li-ion battery research because the humidity cannot be lowered to 10ppm. Please order VGB-5, VGB-6, or VGB-7 or purification system for Li-ion battery research

|

| Shipping Size | 48"×40"×32" |

| Shipping Weight | 320 lbs |