Power

| - AC110V, Single-phase, 50/60Hz, 800W

- AC200V is available upon request

|

| Air Pressure | - 0.5~0.8MPa compressed air or inert gas is required for operation

|

| Sealing Temperature | - 250ºC Max. ( +/- 2 ºC) for the top and bottom sealing die. (We normally recommend 180-200ºC for pouch cell sealing)

|

| Heated sealing time | - 0 ~ 90 seconds adjustable (5 ~ 6 seconds recommended)

|

| Inert Gas Cleaning | - Cleaning with Argon gas and slightly positive pressure before vacuum standing can effectively remove oxygen content and improve the wetting and filtration effect at solid-solid and solid-liquid interfaces of electrodes.

- Cleaning cycle number: 0-90 adjustable

- Cleaning pressure: 0~0.8KPa adjustable

|

| Vacuum Standing and Sealing | - Vacuum level: Max. not less than -95KPa (The vacuum degree can reach mTorr level by using a mechanical vacuum pump)

- Vacuum standing time: 0~900 seconds adjustable

- Vacuum pre-standing time: 0~90 seconds adjustable

- The vacuum pump is not included. Please click here to order at MTI.

|

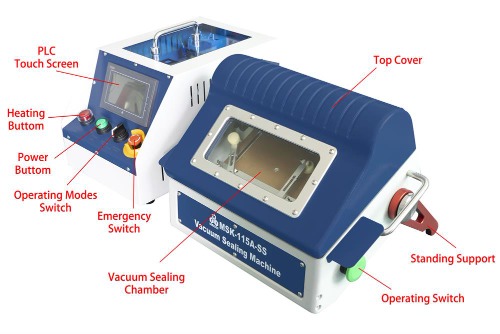

Front and Back Panels    | - A PLC screen was used to set the sealing parameters and show the operation status.

- Inert gas port, compressive gas port, and vacuum ports are installed on the back panel

- You need an air compressor to operate (not included, please click Pic. 1 to order)

- You need an inert gas tank to purge the chamber(not included)

- The vacuum pump is required for final sealing (not included, please click Pic 2 to order)

Pic. 1 Pic. 1 Pic. 2 Pic. 2

|

Sealing Die

| - Max battery size: L100 x W100 x Thickness 12 ( mm)

- Heatable sealing blade: 250oC Max with precision digital temperature control

- Sealing width: 4 mm (The sealing width could be customizable)

- Sealing length: 100 mm Max.

- Sealing evenness: ≤ 0.02 mm overlapping precision of top and bottom sealing dies

- Sealing die type: Sealing blade with rubber buffer (soft-sealing)

|

Sealing Pressure

| - Pressure: 393N Max.

- Consumption: ~ 0.04 L compressed air per sealing

- Please use high-purity inert gasses (Ar or N2), when operating in the glove box. Using Air Compressor driven when operating outside the glove box.

- Please note that the air compressor is not included and is not recommended for use in the glove box.

- Attention: If a gas cylinder is used instead of an air compressor(pic2), a two-stage pressure regulator(pic1) must be installed on the gas cylinder to limit the pressure within the required working range for safe operation. Click here to learn about the installation of a gas regulator.

pic1 pic1  pic2 pic2

|

Dimension

- ( Click picture to see details )

| - Sealing Machine: 400 mm L x 330 mm W x 290 mm H (with cover open)

- Control Unit: 230 mm L x 230 mm W x 290 mm H

- It is easily transferred into the glovebox from the antechamber.

- A flanged tube can be used to install the feedthrough without any gas leaks.

|

| Net Weight | - Sealing Machine: ~16kg

- Control Unit: ~9kg

|

| Warranty | - One-year limited warranty with lifetime support

|

| Compliance | - CE Certified

- NRTL Certification is available upon request at an extra cost

|

| Video | |

| Optional | |

Pic. 2

Pic. 2

Operation Video

Operation Video Die Cutting

Die Cutting