Furnace Structure

| - Double layer steel casing.

- High purity 1800oC grade fibrous alumina insulation

- Alumina processing tube, vacuum & gas sealing flange with valves, vacuum gauge, thermal blocks are included

- Quenching liquid tank is built in bottom for immediate use

- Quench sample upto 50mm dia, x 65 mm L under inert gases and vacuum

|

Power Consumption | Max. 4 KW |

Input Voltage | Single Phase, 220V AC, 50/60 Hz |

Normal Working Temperature: | 800-1600 oC (3002 oF) |

Max. Working Temperature: | 1700 oC (3092 oF) for < 1 hours |

Max. Heating / Cooling Rate: | 5 oC / min above 1200 oC and 10 oC/min below 1200oC |

Heating Zone | 200mm |

Constant Temperature Zone | 65 mm (3") Temperature Accuracy: +/- 5 oC |

Heating Elements | 4 pcs of U-shaped 1800 grade MoSi2 |

Temperature Controller

Temperature controller interface

Optional PC control module

Optional Eurotherm 3204

| Standard temperature controller:

- Proportional–integral–derivative control (PID control) and auto-tune function

- 30 segments programmed with ramping, cooling and dwelling steps

- Built-in over-temperature alarm and thermocouple failure alarm

- +/- 1 ºC temperature control accuracy

- Default DB9 PC communication port (PC control module and software are sold separately. See optional.

Optional:

- MTS-02 PC control module (also including cable and software) is an add-on option for PC control.

- It is recommended to purchase the module together with the furnace. We install and test it before shipping.

- It is recommended to purchase the laptop (with software pre-installed) from us to avoid software confliction.

- Please note the module is not sold solely in the future.

- Eurotherm 3204 Temperature Controller is optional for additional $950 including installation and testing. This package also includes the communication cable (RS485 - USB) and software CD. Click here to view the full spec.

|

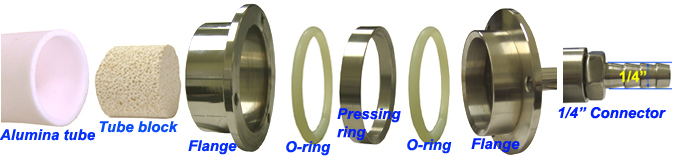

Processing Tube | - 99.8%High purity Al2O3 Ceramic, ID: 54mm; OD: 60 mm x Length 850 mm

- Two fibrous ceramic tube blocks are included for blocking heat radiation from inside tube. (Ceramic blocks must be fully inserted into the furnace chamber before heating)

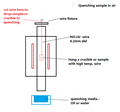

- You may consider using a tungsten wire to hang up a crucible or sample to quench sample ( click Pic right to learn )

|

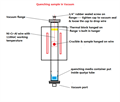

Vacuum Sealing and Valve | - Vacuum pressure can reach 50 mTorr by a quality mechanical vacuum pump and 10^-5 torr by turbo molecular pump. Please click the picture below to see flange assembling details.

- Optional: You may consider using the parts in below to increase the vacuum efficiency

- Please click picture below to learn how to quench sample in gas flow and vacuum

- Approach#1: Traditional wire cut and free-falling ( Fig. 1 & 2 )

- Approach#2: Electromagnetic release and free-falling. (Fig 3 & 4 )

|

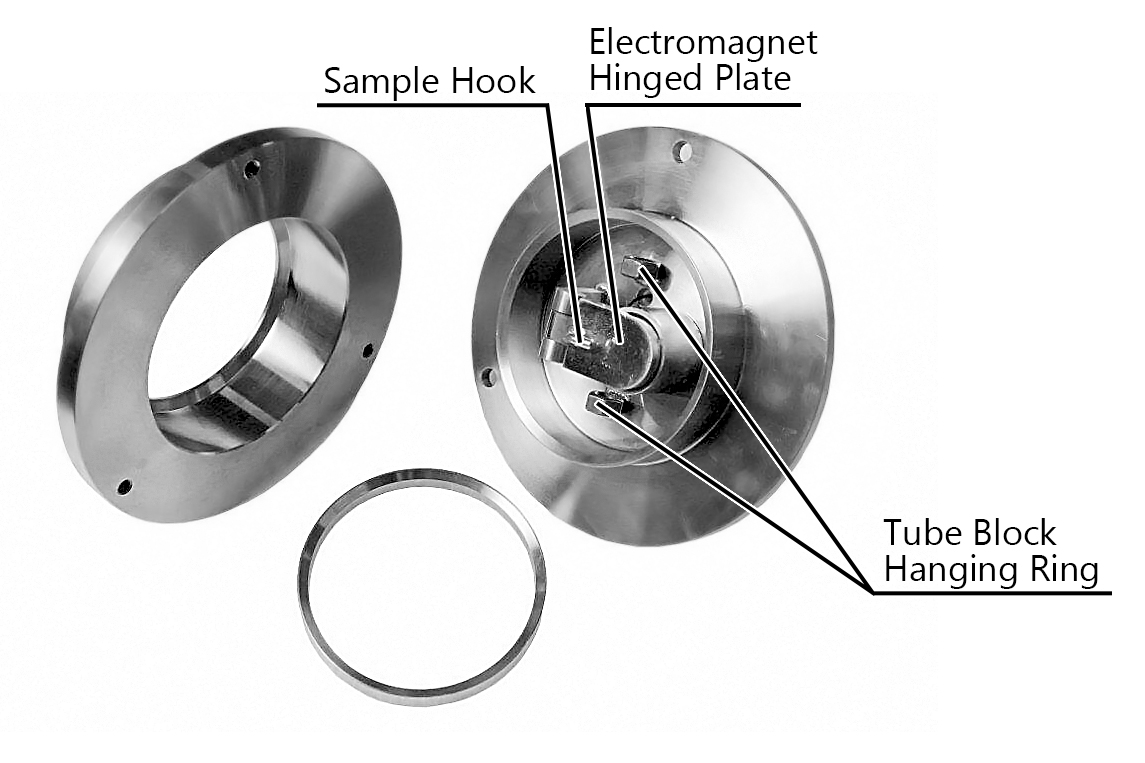

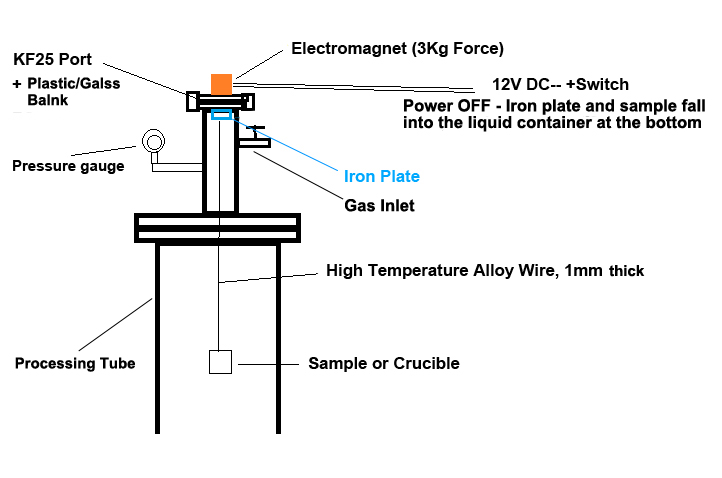

Electromagnet Sample Release Flange & Quenching

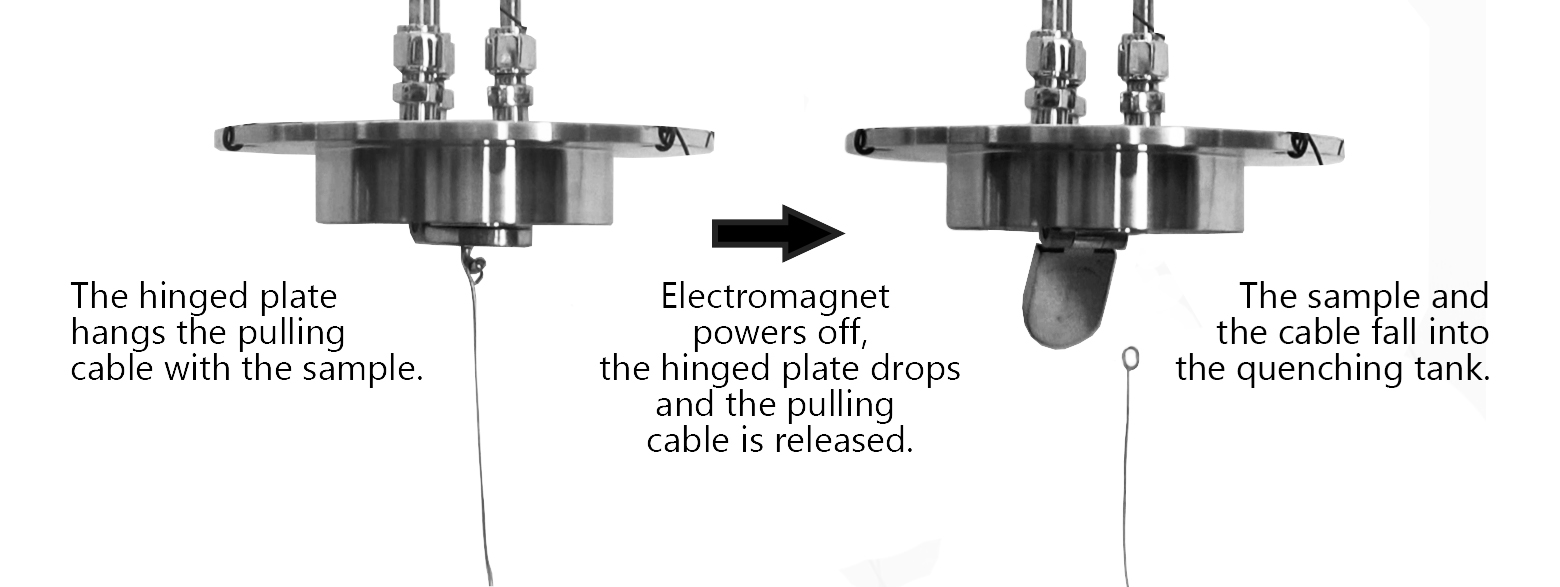

| - Full automatic electromagnet sample release flange

- Hinged plate hooks the cable, which pulls the sample.

- Hinged plate drops when the electromagnet powers off. The sample and the cable fall into the quenching tank.

- Rings are available for hanging the tube block with cables.

- Bottom flange is connected with a 4" gate valve ( manual operated ) via CF-100 adaptor

- The gate valve is connected with a quenching media container in size 400 x400 x 200 H ( mm )

- Caution: You must use ice water or cooled oil as quenching agent if quenching under vacuum.

|  |  |  |  |  | | 1. Flange Structure | 2. Flange Operation | 3. Gate Valve | 4. Quenching Tank | 5. Quenching | 6. Pulling Cable |

- Compared to electromagnet cable drop quenching, traditional approach (Cable Cut Quenching) consumes cables.

|  | | Trad. Quenching in Air | Trad. Quenching in Vacuum |

|

Quenching operation | - One stainless steel tank is located on the bottom of the furnace to contain quenching liquid.

- One large gate valve is built in bottom tube

- One electromagnet is installed on top flange and hold sample hanging wire up to 500 g

- Touch the release button of the electromagnet on temperature control unit, the sample will drop to the liquid tank.

- Before release, sample must fill argon gas to 5 psi and open gate valve

|

Power Cable & Plug | - 10 feet length 10-3 AWG heavy duty UL approved power cable is included. Extra length cable can be ordered by click picture below-left

- The plug is not included. Browse our catalog for compatible plugs or obtain one from a local hardware store.

|

Dimension | |

Net Weight | |

Shipping Dimensions | 48" x 40" x 75" |

Shipping Weight | |

Warranty | One-year limited warranty (Consumable parts such as processing tubes, O-rings, and heating elements are not covered by the warranty, please order the replacement at related products below.) |

Laptop, software & WiFi Control (Optional) | |

Certificates | - CE Certified

- All electric components ( >24V) are UL / MET / CSA certified

- The furnace is ready to pass TUV(UL61010) or CSA certification at extra cost. (please click marks below to learn details )

|