Model |

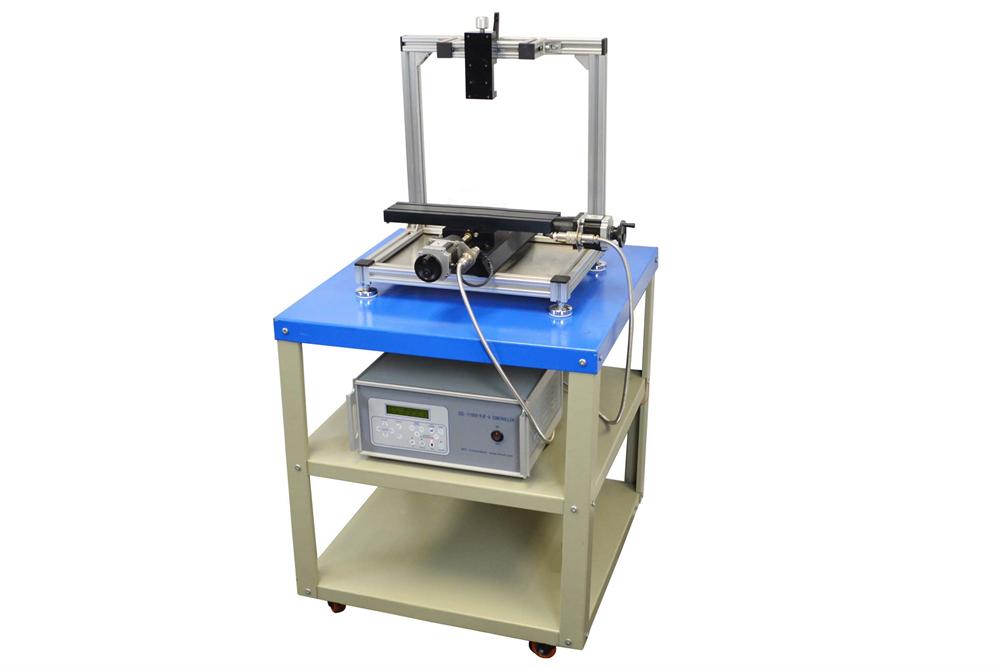

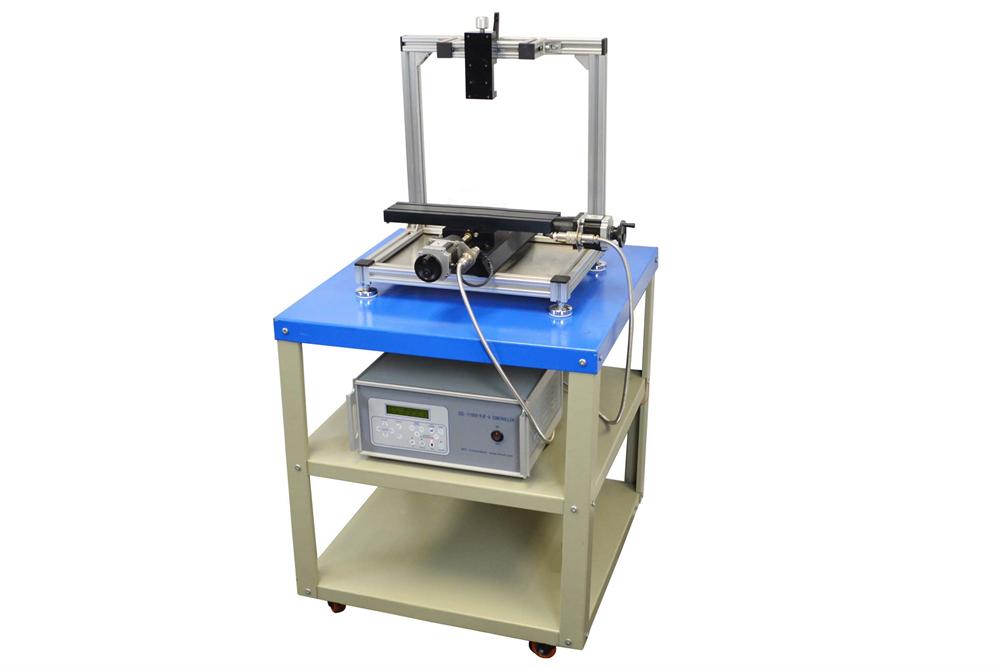

MSK-ESDC-80-Series

|

Features |

• Drum collector with adjustable rotation speed and digital speed display- • Speed adjustable oscillation fixture for holding multiple liquid ejection needles

- • Compact design enables DIY flexibility

- • Compatible with Argon gas environment

- • Rotary drum is made of SS304, and frame is made of Nylon

|

| Input Power | |

Drum Collector |

• Rotation speed: 0 - 450 or 4000 rpm adjustable ( pls choose from option bar )- • Frontward and backward rotation

- • Speed accuracy: +/- 5 rpm

- • Drum size: 80 mm Dia. x 200 mm L

- • Optional drum with sizes of 30 or 50mm Dia. can be ordered separately by contacting MTI

|

Oscillation Fixture

|

• Syringe needle holder to mount up to 7 needles (7 slots of 12 mm Dia. See left picture)- • Two adjustable positions limit sensors to control the fixture movement distance

- • Syringe needle head suggested having 100-200mm distance with collector drum

- • Fixture movement distance: 160 – 330 mm adjustable

- • The syringe needle is not included in the standard package, please order separately.

|

Optional |

• To builds a DIY electrospinning system, you may need- º A high voltage power supply (Click Pic 1 to order)

- º A syringe pump controller to deliver polymer solution (Pic 2 & 3)

- º Ultrasonic spray head ( click Pic.4 to order )

- º An X-Y stage for uniform coating onto a plate collector (Click Pic 5 to order)

- º A fume hood to enclose the system for safety and health (Click Pic 6 to order)

1 1  2 2  3 3

4 4  5 5  6 6

|

Stage Dimensions |

• 480 mm L x 480 mm W x 300 mm H

- •

(click to enlarge) (click to enlarge)

|

| Warranty | - • One-year limited warranty with lifetime suppor

|

| Shipping Weight | |

Operation Video & Instruction |

|

Application Notes |

• The ability to generate aligned fibers and the degree of alignment depends on the

polymer- solvent combination, viscosity, applied voltage, tip-collector distance, and

drum rotation speed.

User is advised to experiment the processing parameters for best results- • Use a properly grounded electrical outlet of the correct voltage and current handling

capacity and away from sources of electromagnetic interference. Improper grounding

may cause charge build-up and damage the unit - • The electrospinning process uses HIGH VOLTAGE! Stay clear of the syringe needle

or drum collector during the process to avoid electric shock! Beware of short circuit

damage to the unit due to leaking or short distance between charged syringe needle

and drum collector - • Solvents and chemicals used for electrospinning may be poisonous, flammable, oxidizing,

or corrosive. It is the user’s responsibility to understand the risks associated with the

process and use proper protections. The user is advised to wear protective clothing,

mask, goggles, and gloves. The electrospinning process should be confined in an

enclosed chamber, such as a fume hood, with proper exhaust handling capability

|