Input Power

|

• Single phase 110 VAC or 208-240 VAC

(selectable at Product Options), 50 / 60 Hz- • 600 W power

|

Vacuum Level

|

• Vacuum range: -95 ~ 0 kPa adjustable- • The vacuum pump is not included. Please click the picture

to the left to order at MTI. - • If you have your own pump with KF25 PORT, Barbed fitting

to KF-25 Adapter is included for immediate use.

|

Sealing Die |

• Max battery size: ≤ 160 mm in length and width, ≤ 12 mm in

thickness- • Sealing width: 5 mm (customizable)

- • Sealing length: ≤ 190 mm

- • Sealing evenness: ≤ 0.03 mm overlapping precision of top

and bottom sealing dies - • Sealing die type: Sealing blade with rubber buffer (soft sealing)

|

Sealing Pressure

|

• Pressue range: 0 ~ 7 kg/cm² adjustable. Vacuum chamber

lid and sealing die need to be driven by compressed high

purity inert gasses with recommended 60 psi pressure.

- • Consumption: ~ 0.1 L compressed air per sealing

- • Please use high purity inert gasses (Ar or N2), when operating

in the glovebox. Using Air Compressor driven when operating

outside the glove box.

- • Please note the air compressor is not included and not

recommended to use in the glove box.

- • Attention: If a gas cylinder is used instead of air

compressor(pic2), a two-stage pressure regulator(pic1)

must be installed on the gas cylinder to limit the pressure

within the required working range for safe operation.

Click here to learn the installation of a gas regulator.

pic1 pic1  pic2 pic2

|

Sealing Temperature |

• Two independent digital temperature controllers are built in.- • Temperature range: 50 ~ 260 ℃ adjustable with control

accuracy of +/- 2 ℃ - • Recommended temperature: 200 ℃ for top sealing die, and

160 ℃ for bottom sealing die

|

| Sealing Time | - • 0 ~ 99 seconds adjustable (3 ~ 4 seconds recommended)

|

Size

|

• Dimension for 220V version:

408 mm L x 365 mm W x 480 mm H- • Dimension for 110V version:

340 mm L x 380 mm W x 580 mm H - • The compact 115A is suitable for working under glove box

environment while with plenty space for other materials and

equipment.

|

| Net Weight | |

Glove Box Compatibility

|

• A KF40 Feedthrough with all necessary wire and tube is

included to allow operating inside the glove box.

- • NO. 1 Vacuum Release

- • NO. 2 Gas Inlet Port (Tube size is 8), for all pneumatic

component such as Die and Lid cover, must use Inert gas

when operating in the glove box.(Gas Inlet Pressure ~116 psi)

- • NO. 3 Gas Outlet Port

- • NO. 4 Vacuum Port for Connecting the vacuum pump

( ~11.5mm OD, Barbed fitting to KF-25 Adapter is included

TO connect to pump).

- • Attention: High purity inert gasses are required for the

operation of the machine.

|

Optional Supporting Rack

(For 220V version only) |

A customized supporting rack for extra height is available upon request. Please contact us if you want to order the rack at extra cost.- Please click the picture on the bottom right to see the configuration of the sealer in a glove box.

- Note: The supporting rack is for 220V version ONLY! The 110V version comes with extra height (Please check the row "Size" to compare), therefore the supporting rack is not needed.

|

| Warranty | - One Year limited warranty with lifetime support

|

| Compliance | - CE Certified

- NRTL Certification is available upon request at extra cost

|

Operation Manual & Video

|

|

Application Notes |

• Please wear gloves to operate the machine.- • Beware of the automatic vacuum chamber lid.

Only one operator is allowed for this equipment. - • Please clean the sealing dies after each use. Clean the sealing

die after it has cooled down to avoid corrosion by the

electrolyte. - • Check the level and smoothness of sealing die surface every

week. If there is serious damage to the sealing die, please

contact MTI to order a replacement. - • Lubricate the cylinder every week

- • Check the screws in sealing dies and stage every month.

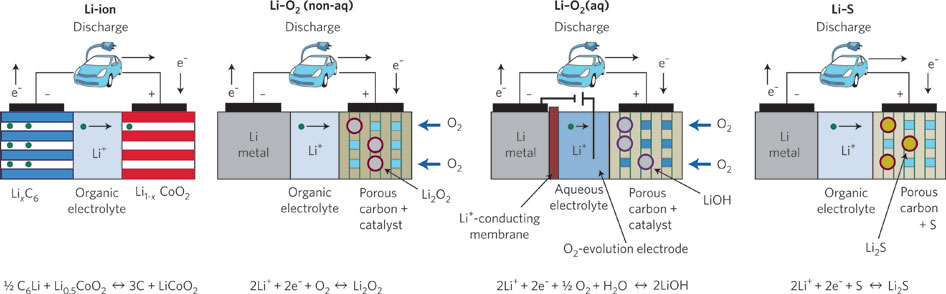

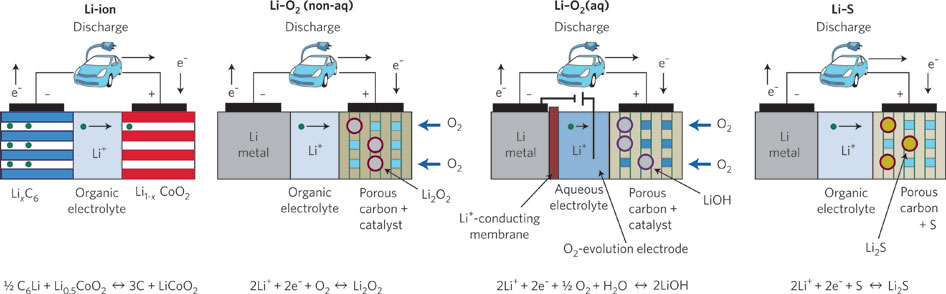

Make sure they are tightened. - • Compact design enables the operation inside the glove box

with Ar atmosphere where Lithium Sulfur, Lithium Air, Lithium

Solid State or Li-ion half cell will be assembled.

Please click the images below to understand these

technologies and how it fits in a glove box.

|