Structure & Features

|

• Manual - Auto dual model control. Manual control

over the current provides a faster initial heating up

but might lose accuracy during the temperature

holding. Auto mode is a good compensation for that.

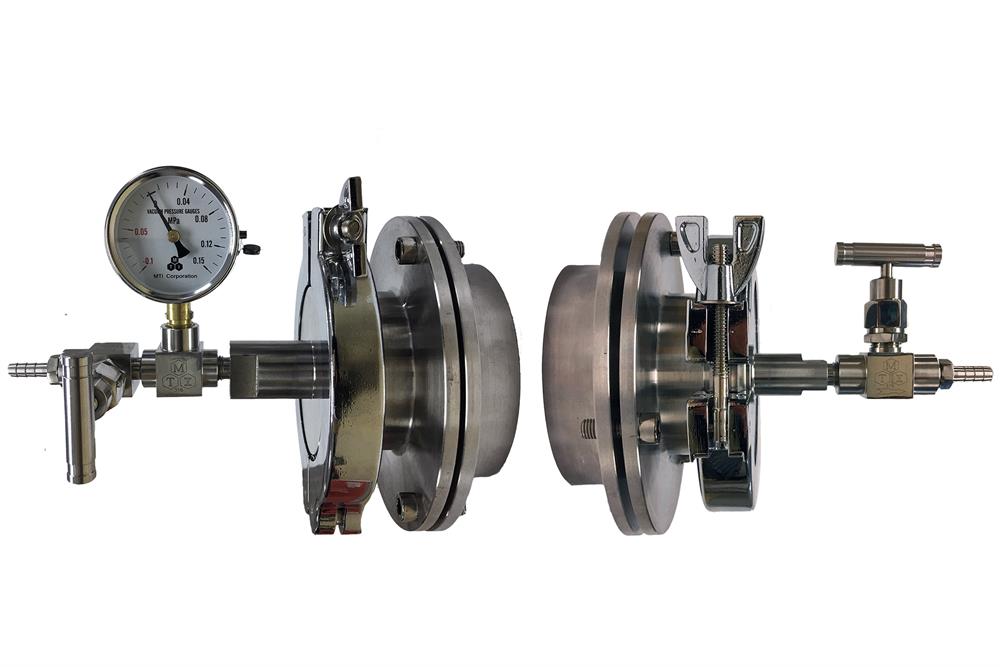

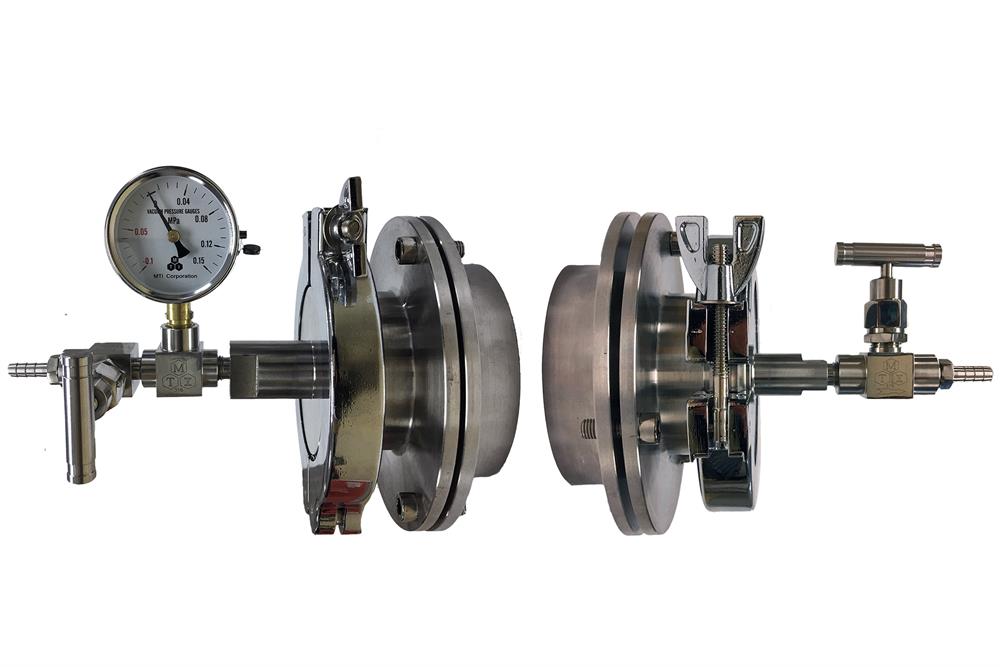

- • KF50 rotatable adaptor with quick clamp enables

easy installation onto vacuum chamber and tube

flanges.

- • The magnetic fluid sealed inline swivel prevents

gas/vacuum / electrical lines twisting in the event of

KF50 flange rotation. (Optional, please select the

features in the optional bar)

- • Tungsten coil heater and alumina crucible for high-

temperature evaporation up to 1300 ºC.

- • Precision temperature control with 30 programmable

segments and +/- 1 ºC accuracy.

- • 1/4'' tube fitting with needle valve is built-in for gas

purging or evacuation.

- • Using this tool, we can modify your tube furnace into

evaprating coater,

|

Input Power |

• Input voltage: 208 - 240 VAC 50/60 Hz, single

phase, 500W- • Power cable included without the plug

|

Temperature Control & Heaters

|

• Working temp: 1350ºC Max(<1hrs)., and 1200ºC for

continuous heating. S type thermocouple is included.

- • Tungsten coil heater with the S type thermocouple is

inserted to the bottom of alumina crucible for precise

temperature measurement and control.

- • Temperature control console provides up to 30

segments programmable with +/- 1 ºC accuracy.

500W DC evaporation power supply with max.

operating current @ 30Amps. The time settings of

temperature controller are in seconds. Recommend

to limit the temperature heating/cooling rate to < 30

ºC/min. (Optional, if you decide to use your own

temperature controller and power supply, please

make sure they meet the manufacturer's

recommended specs - 500W DC evaporation

power supply with max. operating current @

30Amps)

- • For continuous heating above 800 ºC, alumina fiber

must be used to fill the gap between the refractory

liner and crucible. It is important to bury the tungsten

coil to prevent heat dissipation

|

Sample Crucible

|

• 0.7ml alumina crucible with tungsten heating coil

surrounded.- • S type thermocouple inserts for accurate

temperature measurement of the source material.

|

Gas Inlet |

• 1/4'' tube fitting is built in for chamber purge or

forming gas processing- • One needle valve is built-in to control gas flowing

rate

|

Optional |

• Quick disconnect flange with KF50 vacuum port can

be easily adapted to magnetic fluid seal, in this

case, a tube can be used to create a sealed

environment with protective gas or vacuum.

- • The magnetic fluid sealed inline swivel prevents

gas/vacuum / electrical lines twisting in the event of

KF50 flange rotation. (Optional, please select the

features in the optional bar)

- • The temperature controller is optional, please select

this feature in the optional bar.

2'' Tube Flange 2'' Tube Flange

60mm O.D; 80mm O.D; 100mm O.D Tube Flange |

Overall dimension

|

( The length of insert rod can be customized upon request )

|

Compliance |

• CE Certificate- • NRTL or CSA cerification is available upon request

at the extra cost.

|

| Warranty | - One-year limited warranty with lifetime support

|

| Net Weight | |

Operation Instructions | |