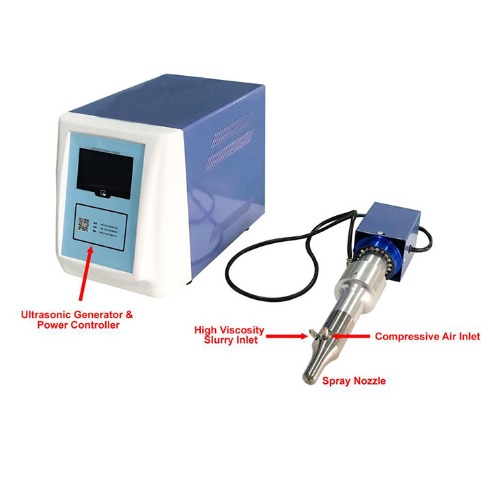

Ultrasonic Generator

|

• Input power: AC 208 - 240 V, 50/60 Hz- • Ultrasonic output: 0 - 3.5 KW adjustable

- • Ultrasonic frequency: 20 kHz

|

Ultrasonic Converter |

• PZT (piezoelectric zirconate titanate crystal)- • Diameter: 25 mm

|

Spray Nozzle

|

• Ultrasonic duty cycle (Transfer efficiency): 0.1 - 99.9 %

- • Outer diameter: 20 mm

- • Inner diameter: 1 - 2 mm

- • Spraying speed: 0.1 - 0.3 ml/min

- • Compressed air flow rate: 1 - 500 sccm

- • Liquid solution viscosity range: 1 - 2,000 mPa·s (cPs)

- • Liquid Inlet Fitting:

|

| Drop Size | |

Dimension |

• Ultrasonic generator: L 400 mm x W 225 mm x H 285 mm- • Spray nozzle: L 450 mm x H 86 mm

-

|

| Compliance | |

| Operation Instructions |  |

| Warranty | - • One year limited warranty with lifetime technical support

|

Optional |

• You will need an Infusion Syringe Pump to carry and delivery

liquid for uniform coating. Please click the pictures below to

order digital or PC controlled Infusion Syringe Pump at extra

cost (Pic. 1, 2, 3)

- • You may need a heating plate for the spray pyrolysis coating.

Please click Pic. 4 to order

- • You may need the X-Y axis CNC stage to DIY a coater, Please

click Pic. 5 to order (Pic. 5)

- • Please put the device into a fume hood for safety concern

(Pic. 6)

- • For the DIY Ultrasonic Spray and Electro-spinning devices

Pic. 1 Pic. 1  Pic. 2 Pic. 2  Pic. 3 Pic. 3

Pic. 4 Pic. 4 Pic. 5 Pic. 5  Pic. 6 Pic. 6

|