| Max. Pressure |

• 5 Metric Ton- • Pressure gauge is built in manual hydraulic pump

|

Gauge Pressure Value

to Force Conversion

|

| Pressure Displayed on the gauge(MPa) | 11 | 22 | 33 | 44 | 56 | | Actual Force Applied to the Hydraulic Cylinder (Ton) | 1 | 2 | 3 | 4 | 5 |

• Displayed pressure value to actual applied force conversion: 1 MPa = ~ 0.09 Ton- • The actual force applied to the vessel cylinder (Ton) equal to the force applied to your working piece

- • For calculating the actual pressure (Mpa) applied to your working piece, please follow the equations below:

- • P = T x g x 10/ (πr^2)

- º P: pressure (Mpa) applied to your working piece

- º T: force (metric ton) applied to the pressure vessel cylinder

- º g: standard gravity. g ≈ 9.8 m/s2

- º π: ~3.14

- º r: radius (cm) of the pressure vessel (1.5 cm)

- º *1000 Kg = 1 Metric Ton; 1 Mpa = 10 Kg/cm2

|

Hydraulic Pump &

Cylinder |

• 5T Max.- • Pump is separated from the cylinder for safe operation

- • Cylinder diameter: φ30 mm

|

| Operation Temperature | |

Bottom Cylinder

Traveling Distance | - • 0 - 8 mm. The bottom cylinder (piston)

|

| Max. Working Space | |

Overall Dimension

|

• Outer dimension: 450mm L x 230mm W x 560mm H- • Inner dimension: 381mm L x 164mm W x 400mm H

- • Customized width and height of the press frame are available upon request.

|

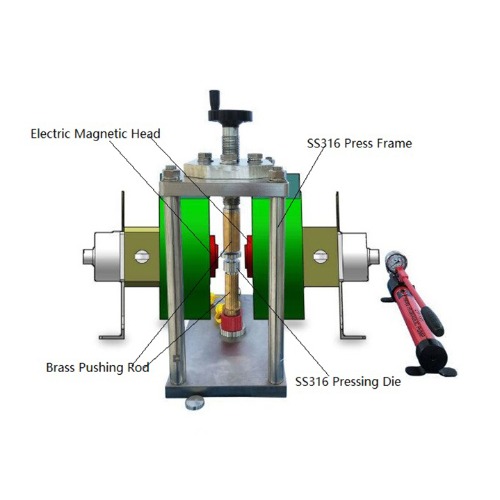

Pressing Die

| - • One set of SS316L 1/2" (12.7mm) ID drying pressing die is included

- • Click picture the left to order spare die

- • Customized die is available upon request

- • Note: please never use hardening tool steel die under the magnetic field

|

| Pushing Rod |

• Two pushing rod ( top and bottom) is made of brass- • diameter 30 mm

|

Electromagnetic

Operation (Optional) |

• Max. inner dimension for the electromagnetic machine: 390mmH x 340mm D x 600mm W, which can insert

< 350mm electric magnetic head inside the frame.- • MTI does not provide electric magnet but can help you to choose or purchasing. For example;

|

| Net Weight | 75 kg |

Shipping Weight &

Dimension | 260 lbs; 48"x40"x40" |

| Optional |

• Electric hydraulic pump is available upon request.

-

|

| Warranty |

• The pressing machine was quality inspected in the USA, lifetime support is provided- • One year limited standard warranty (Extended warranty is available up to 5 years at extra cost).

|

| Compliance |

• CE certified- • NRTL certification is available upon request at the extra cost

|

Operation Video and

Instructions |

Installation Guide

|

| Application Notes |

• The pressing die cannot be used for pressing powder with the particle size < 30 microns. Small particles

may slip into the gap between pushing rod and steel sleeve and cause damages to the sleeve during the

compression. Ball mill and sieve the powder and apply only the 32~75 microns powder to the pressing

die to avoid the damages. Please consider using the 3'' Dia. Sieve Set No.200&450 Mesh to separate the

32~75 microns particles from the powder clumps. Please clean the mold via ethanol after the completion of

each experiment.

- • Do not raise the bottom cylinder (piston) more than its maximum traveling distance. (25 mm)

- • Warning: Customers must always wear protective goggles during operation !!!

- • Operate the presser inside the glove box is not recommended.

|