System Structure

|

• Aerosol Generation: 1.7 MHz Ultrasonic Enhanced Bubbler can "evaporate" catalyst liquid with

literally no heat generated. A stainless steel liquid collector connects inline with the ultrasonic bubble

can prevent condensing liquid from streaming into the furnace tube chamber. - • Thermal Decomposition: three-zone ( 900mm length ) tube furnace can be heated up to 1200C

maximum to pass the droplets flux across the temperature and atmosphere regulated firing zone,

chemical, and physical conversion processes proceed. - • Nanopowder Collection: 30KV electrostatic precipitator (700 ml ) can effectively collect nano-size

particles from the carrier gas flow - • The furnace can be tilted to avoid liquid flow back atomizing tank

|

Tube Furnace -

Thermal Decomposition

|

Voltage & Power |

• Single Phase, 208V~240V AC, 50/60 Hz (30A breaker required)- • Max. 7 KW

|

Working Temperature |

• 1100oC continuous- • 1200 oC Max. < 1 hours

|

| Max. Heating / Cooling Rate | < 20oC / min

|

Heating Zone & Constant Temperature Zone |

• Three heating zone, 300+ 300 + 300 mm ( 900mm L total)- • Constant temperature zone: 600 mm with +/- 2oC

( if 3 zone at same )

|

Heating Elements

| - • Fe-Cr-Al Alloy doped by Mo

|

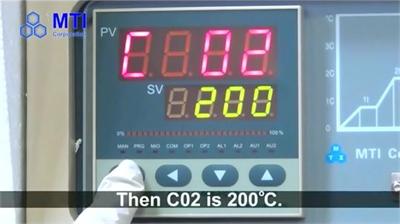

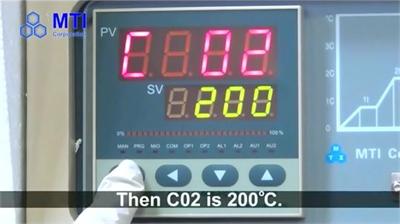

Temperature Controller

|

• Three digital temperature controllers with 30 programmable

segments for precise control of heating rate, cooling rate and dwell

time.- • Built-in over-temperature alarm and protection allow for operation

- • +/- 1 ºC temperature accuracy.

- • RS485 Communication Port.

- • Precision Eurothermo controller is available with +/- 0.1 oC

accuracy

|

Processing Tube |

• One fused quartz tube is included with ID 20.5 x OD 25 mm x L

1400 ( mm)

|

Sealing Flanges

& Fittings

|

• Left side sealing KF flange which connects atomizing bubbler and

1" quartz tube with vacuum gauge.- • Right side KF flang connects to the electrostatic precipitator.

Left

Right

|

Aerosol Generation

|

Ultrasonic atomizing bubbler

|

• 220VAC, 1.7 MHz Ultrasonic Generator- • Ultrasonic power is adjustable with 8 levels

- • 316 Stainless Steel liquid container with a fluoropolymer sealing

ring - • The continuous or timed mode can be set. For timed mode, time

can be adjusted from 30 minutes to 180 minutes. - • A liquid injection pump is equipped with a 60 ml plastic syringe.

The speed range for the liquid injection pump is 0.004 ml/min - 70

ml/min - • A floating flow meter is included to control the carrier gas flow rate

within 0-200 SCCM. - • vA mass flow controller (MFC) is optional to precisely control the

flow rate.

|

Nanopowder Collection

|

High Voltage Supply

|

• AC 220V 50/60Hz, 30 W Max. power consumption- • Digital Voltmeter and Current meter, 30KV, 1.0 mA max.

- • Output voltage and current can be set by using knobs on the front

panel and read from the digital display - • Built-in Arc Protection Circuit

|

Electrostatic Precipitator

|

• KF25 quick clamp and flange enables the quick coupling to the

furnace processing tube- • 1/4" gas outlet built-in

- • Another KF25 port is built-in with the collector to connect the

vacuum pump, which is required, but not included - • PEFE plates are installed on top and bottom to insulate high

voltage electrodes - • Adjustable supports keep the collector leveled with the furnace tub

|

| Net Weight | ~150Kg |

| Dimensions |  ( click the picture to see details) ( click the picture to see details) |

| Warranty | One year limited manufacturer warranty with lifetime support (consumable parts such as furnace liner, processing tubes, and O-rings are not covered by the warranty, please order replacements at related products below). |

Laptop, software & WiFi Control (Optional)

|

• Brand new laptop with Microsoft Window 10 and Microsoft Office

2013 (30 days free trial) for immediate use.- • Labview Based Temperature Control System (EQ-

MTS01) enables the user to edit temperature profile, manage

heat-treatment recipe, record and plot data for MTI furnaces.

|

Compliance

|

• CE Certified- • NRTL or CSA certification (UL61010) is available upon request at

extra

|

Application Notes

|

• A two-stage pressure regulator must be installed on the gas

cylinder to limit the pressure to below 3 PSI for safe

operation. Click here to learn the installation of a gas regulator.- • Please tilt furnace in 10 - 15 degrees to avoid liquid back to

atomizing bubbler - • It is the customer responsibility to achieve the ideal parameter for

particle size. Usually, the liquid injection rate and carrier gas flow

rate has an important influence on particle size. - • The SEM picture left is SnO2 particle ( ~ 500 nm - 5 um) generated

by the equipment via Stannic chloride solution at 800oC

|

Operation Video & Instructions |

|