System Features

|

• Aerosol Generation: 2.4MHz Ultrasonic Enhanced Bubbler can "evaporate" target solution with literally

no heat generated. An elongated Tee tube wrapped by a heating tape that connects inline with an

ultrasonic bubbler can prevent condensing liquid from streaming into the tube furnace and promote the

generation of aerosol.

• Thermal Decomposition: Tube Furnace can be heated up to 1200C maximum. Bypassing the aerosol

flux across the temperature and flow rate regulated firing zone, chemical and physical processes may

be proceeded. • Nanopowder Collection: an electrostatic precipitator (1.2 L, up to 30 kV) can effectively collect

nanoparticles from the carrier gas flow

|

Tube Furnace -

Thermal Decomposition

|

Voltage & Power | |

Working Temperature |

• 1100 °C continuous

• 1200 °C Max. < 1 hours

|

| Max. Heating / Cooling Rate | |

Heating Zone &

Temperature Uniformity | |

Heating Elements

| - • Fe-Cr-Al Alloy doped by Mo

|

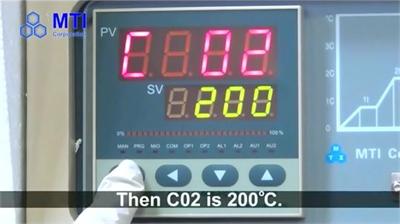

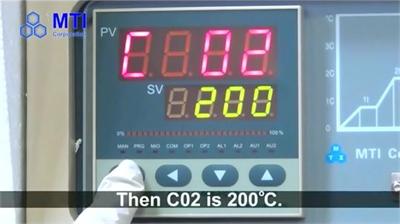

Temperature Controller

|

• PID automatic control, 30 programmable segments for precise control of

heating rate, cooling rate and dwell time.

• Built-in over-temperature alarm and protection allows for operation

without the attendant. • ± 1 ºC temperature control at dwelling process • RS485 Communication Port.

|

Processing Tube | |

Flanges & Fittings | |

Aerosol Generation |

Utrasonic Enhanced Generator

2.4MHz 2.4MHz

1.7 MHz 1.7 MHz

|

• 110 VAC, 2.4 MHz Ultrasonic Generator

• Fluoropolymer coated liquid container and Fluoropolymer sealing

gaskets • In-situ optical sensor and valve for keeping the liquid level to the correct

height and preventing damage to the nebulizing element. • Ultrasonic power programmable, 0~100%, 5% increment. • You may choose 1.7MHz ultrasonic spraying system at a lower cost

|

Flow Meter |

• A 0-100 ml/min floating flow meter is included to control the carrier

gas flow rate.- • Mass flow meter is optional at extra cost.

(EQ-MFC-GFC-LD or EQ-VPC-30-LD)

|

Nanopowder Collection |

High Voltage Supply

|

• AC 220V 50/60Hz, 50 W Max. power consumption

• Digital Voltmeter and Current meter, 30 kV, 1 mA max. • Output voltage and current can be set on the front panel and read from

the digital display • Constant current/Constant Voltage mode of operation • Built-in Arc protection circuit

|

Tubular Electrostatic Precipitator

| |

| Net Weight | |

| Overall Dimension | - • 200 (L) x 40 (W) x 55 (H) cm

|

| Shipping Dimension | |

| Shipping Weight | |

Warranty |

One year limited manufacturer warranty with lifetime support (consumable parts such as furnace liner, processing tubes, and O-rings are not covered by the warranty, please order replacements at related products below).

|

Laptop, software & WiFi Control (Optional)

|

• Brand new laptop with Microsoft Window 10 and Microsoft Office 2013

(30 days free trial) for immediate use.- • Labview Based Temperature Control System enables the user to edit

temperature profile, manage heat-treatment recipe, record and plot data

for MTI furnaces. - • A wireless remote control provides up to 300 meters operating range.

- • Above features are available upon request at an extra cost

(up to $1,000). Please contact us for more information

|

Compliance

|

• CE Certified- • NRTL or CSA certification (UL61010) is available upon request at extra

cost.

|

Application Notes

|

• A two-stage pressure regulator must be installed on the gas

cylinder to limit the pressure to below 3 PSI for safe operation.

Click here to learn the installation of a gas regulator.- • Never heat the furnace while the gas valve is closed and a positive

pressure condition exists within the furnace chamber. The pressure

gauge must be used to closely monitor the chamber condition at all

times during the heating. - • Wrapping Aluminum foil to achieve better thermal conductivity.

|

Operation Instructions |

|