Features

|

• Combine the benefits of both spin and spray, enabling dense and uniform liquid-phase coating

onto a large substrate- • Applications include low-temperature precipitation (e.g., for RF/microwave ferrites deposition),

polymer coating, powder and composite material coating, and coating on a patterned / uneven

substrate - • The system also works on spin alone and spray alone modes

|

Spin Coater |

• Vacuum chuck with adjustable substrate holders for holding flat substrate up to 12" diameter or

8" square- • One oil-less pump for the vacuum chuck is included and controlled by the spin coater

- • Spin speed: 300 - 3000 rpm adjustable

- • For safety concerns, the speed is recommended to be limited to 2000 rpm for wafers larger

than 8"

|

Ultrasonic Spray Nozzle |

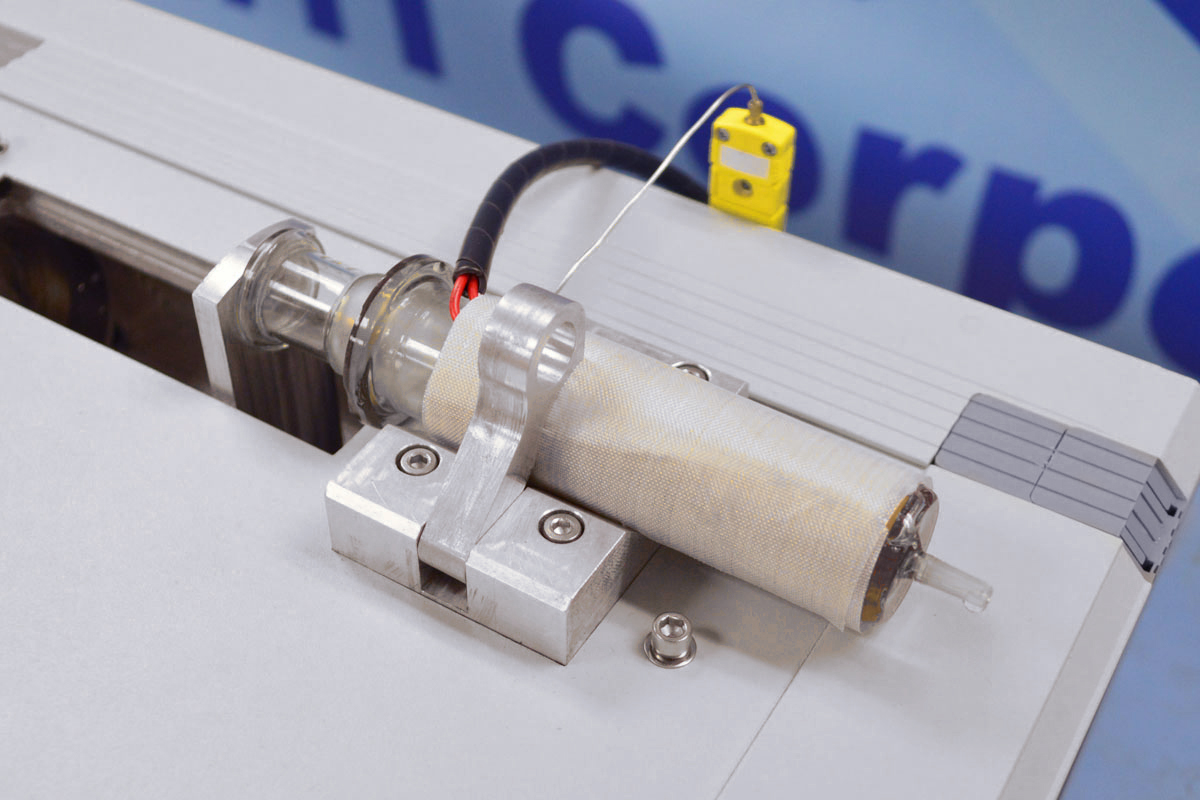

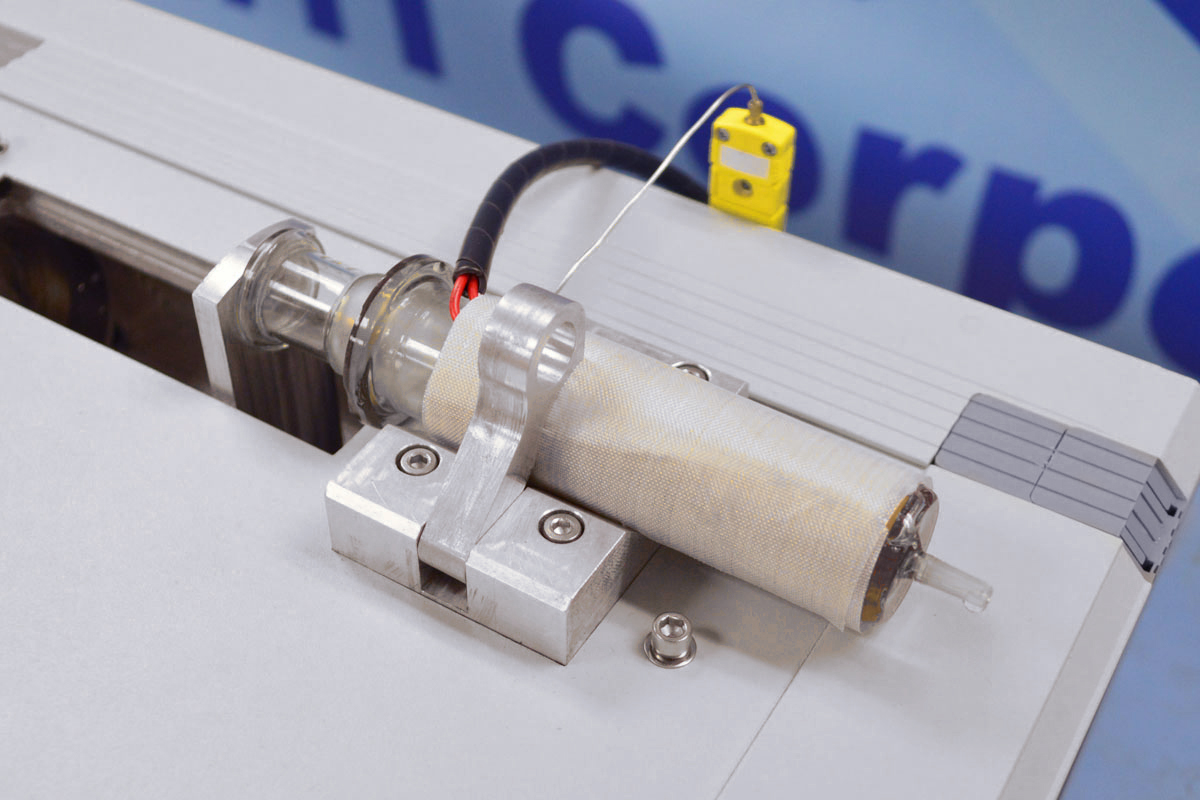

• One ultrasonic generator with two ultrasonic sprays nozzles with compressed air shaper is

included- • Two spray nozzles with the KF-25 adapter are included. (Click the first picture from right to see

details) - º One cylindrical type -- narrower spray ~20 mm diameter

- º One cone type -- wider spray ~40 mm diameter

- • Recommended compressed air pressure for the aqueous solution: ~2 psi

- • One flow meter is integrated for regulating and monitoring the compressed air flow

- • Fluid viscosity range: 1 - 50 mPa·s (cP)

- • One swing arm for mounting ultrasonic spray head is built-in with adjustable speed and

movement range

|

Heatable Syringe Pump |

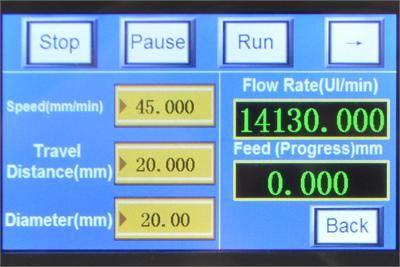

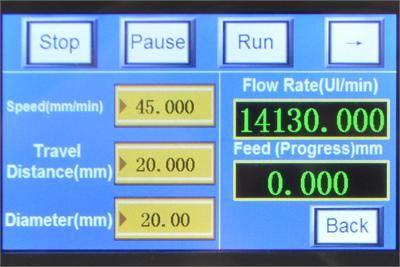

• A heatable syringe pump with LCD touch screen control is included for delivering liquid to the

ultrasonic nozzle- • One 50 mL syringe is included for immediate use. The unit can accommodate syringe with

0.4 - 30 mm diameter - • Pumping rate: 0.1 - 45 mm/min adjustable (0.08 mL/min - 35 mL/min for the included 50 mL

syringe) - • Flexible Polyimide heater with 30 segments programmable temperature controller is built-in

for heating up to 75 °C

|

Heat Lamp and Control

|

Duo heat lamps (1000 W max power. Up to 80 ºC) with thermocouple and temperature controller can be ordered at extra cost for heating substrate by radiation (up to 65 ºC with 12" metal substrate)

|

Optional

|

• MTI strongly suggests you place the spin-spray coater inside a fume hood for health and safety

concerns. The spin-spray system without heat lamp can fit into MTI's bench-top fume hood

(Click Pic 1 to order)- • For the above application, an independently controlled, a two-channel heatable syringe pump

can be ordered at extra cost to replace the standard syringe pump (Click Pic 2 to order) - • Customized Multi spray head is available upon request ( pic 3 )

- PIC 1 - PIC 1  - PIC 2 - PIC 2  Pic 3 Pic 3

|

Utility Requirement |

• Power: 208 - 240 VAC, 50/60 Hz, 3000 W in total- • Gas: ~2 psi compressed air for the ultrasonic nozzle. Air compressor is also available for order

at MTI - • Attention: If a gas cylinder is used instead of air compressor(pic2), a two-stage pressure

regulator(pic1) must be installed on the gas cylinder to limit the pressure within the

required working range for safe operation. Click here to learn the installation of a gas

regulator.

pic1 pic1  pic2 pic2

|

| Net Weight | |

Shipping Weight & Dimensions | |

Compliance |

• CE Certified- • NRTL certification is NOT available temporary.

|

Warranty |

• One year limited with lifetime support

- • Rusting and damage due to improper storage condition or maintenance are not covered by

warranty

|

Operation Manual & Video

| |

Application Notes

(Optional 15“ Diameter with three ultrasonic spray heads is available upon request ) |

• The picture on the left shows an example of spin spray coater complete configuration- • It is the user’s responsibility to understand the risks associated with the process and use proper

protection. Solvents and chemicals used for the process may be poisonous, oxidizing, or

corrosive. Spinning a large/heavy substrate at high speeds runs the potential risk of substrate

flying out and shattering. The user is advised to wear protective clothing, mask, goggles, and

gloves. The process must be confined in a fume hood (Order at the Optional section) with

proper exhaust handling capability. Keep the fume hood sash (window door) lower than the

spinner stage during experiments. - • The film coating quality depends on the solution viscosity, substrate spin speed, substrate

heating, and ultrasonic spray parameters, etc. The user is advised to experiment with the

processing parameters for best results - • Do not overflush the water bowl/base with any kinds of liquid. Excess liquid will leak into the

motor shaft and cause damage. Please use fabric cloth to wipe out the liquid residues in the

bow/base. For more details about the cleaning procedures, please review the cleaning

instruction for the spin coaters - • In order to achieve optimal coating quality, please consider cleaning the substrate with a

plasma cleaner (Click the pictures below for more details) prior to coating. It will significantly

reduce the surface tension on the substrates

Reference Articles |