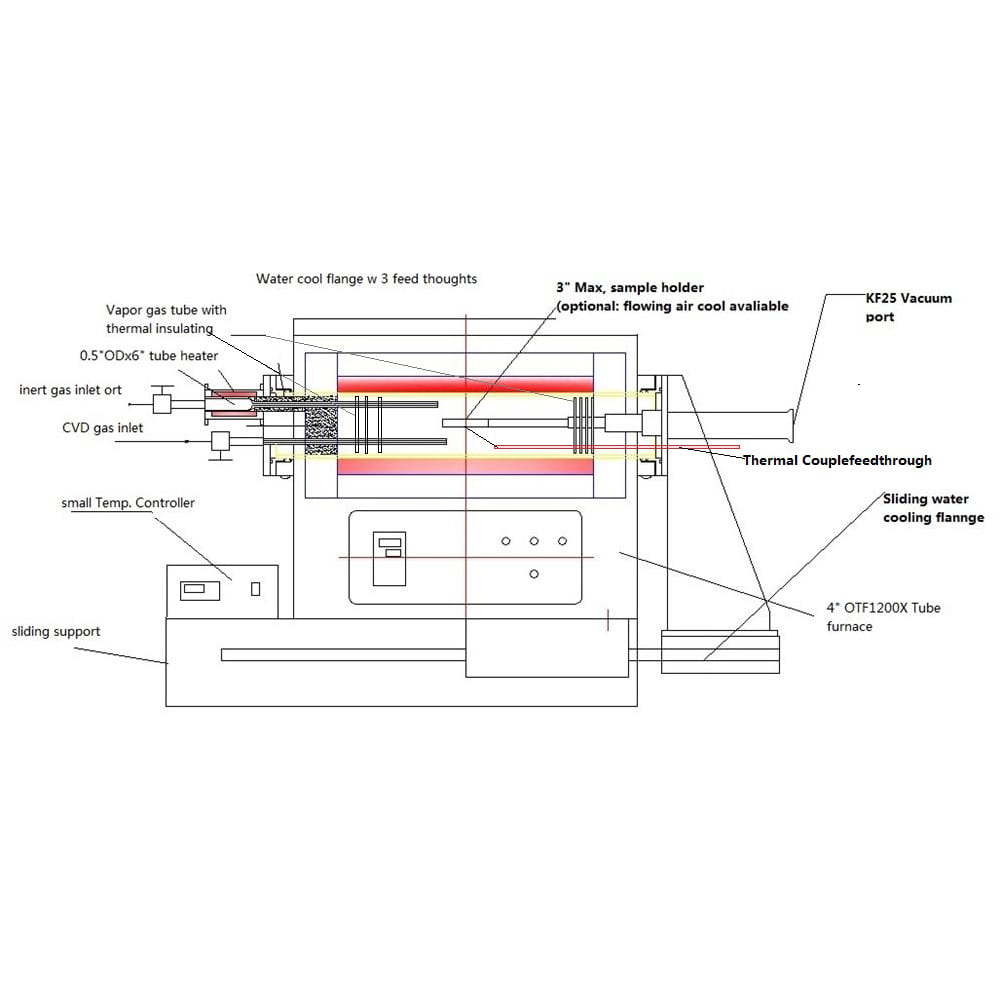

Furnace and Preheater

| - º Water cooling flange on left-side between the heater and furnace is used for

pre-heated gas input and sealing

- • Four-channel gas inlet ( 1/8" Dia tube and tube fitting) are built-in on the left side flange

• One small heater is attached to the left side flange of the furnace to preheat input gas, liquid,

or evaporate solid chemical, which will be then delivered to CVD furnace:

Please click picture left for more details:- º 1.2''O.D x 6''L SS tube as the heating chamber

- º 600ºC Max. working temperature

- º Flange on the left side is for gas sealing and input

|

| Rated Voltage | Single Phase, 220V AC, 50/60 Hz, AWG 8# Power cord is included (without plug) |

| Power consumption | Max. 3600 W (20 A breaker required) |

Heating Zone |

• CVD Furnace: 440 mm- • Constant temperature zone: 100 mm

- • Gas Heater: 150mm

|

Working Temperature |

• CVD Furnace:- º Max heating temperature: 1100°C ( < 2 hour )

- º Continuous working temperature: 200~1000°C

- º Max heating & cooling rate: 20°C/min

- • Heater:

- º Continuous working temperature: RT~600°C

- º Max heating & cooling rate: 20°C/min

|

Temperature Control

|

• CVD Furnace and Heater (separate temp control):- º Digital controllers with PID/self-tuning functions and 30 segments programmable

- º Thermocouple: K type thermocouples, which feed through the right side flange and

control furnace temperature. - º Control accuracy: +/- 1°C

- º RS485 Communications Port

|

Vacuum

and Gas Sealing & Flange

|

The right flange of CVD furnaceLeft flange (between CVD Furnace and Heater) with four 1/8'' Swagelok fittings for 1/8'' tube:

- • Two 1/8'' fitting on the flange for independently and directly delivering any gas into the

CVD furnace - • One 1/8'' fitting for delivering heated gas from heater to CVD furnace

- • One 1/4'' fitting for bypassing the gas (without heating) to the CVD furnace

(inside the CVD furnace, the gas tube is merged with the heated gas pipe by a T fitting)

Note: How gas pipe assembled in the CVD furnace through above 1/8'' fitting:- • One 1/4'' quartz tube delivers the vapor gas from heater(also the bypass gas by a T fitting)

- • Two 1/4'' quartz tube delivery extra gas via the two separate 1/8'' fitting on the big furnace left

the flange - • These three 1/4'' quartz tubes inside CVD furnace is in parallel and vertically 1'' higher than

sample holder - • These three 1/4'' quartz tubes can be easily removed to clean or replaced once get stuck

or corroded

Heater:- • Left flange: one 1/8'' gas fitting to deliver gas to the heater for pre-heating and then to

CVD furnace - • On the right side to CVD furnace with necessary thermal block material to minimize the

temperature gradient at the interface between the heater and CVD furnace - • Furnace Chamber Installation

- • 2- 1/4" pipe adapter is installed on each flange

|

The optional Liquid Injection device |

For direct liquid CVD ( DLCVD), you may consider below devices for liquid injection: ( click Pic to order )

|

Net weight

| 110kg

|

Dimensions

|

• Standard: 62"L X 18"W X 23"H- • Maximum: 80"L X 18"W X 32"H (Lid open and right-side flange slided out)

|

Warranty

|

• One year limited warranty for electrical parts. ( Consumable parts such as processing tubes,

o-rings and etc are not covered by the warranty)- • You may order replacement quartz tube here: EQ-QZTube-SF

|

Laptop, software & WiFi Control (Optional)f |

• Brand new laptop with Microsoft Window 10 and Microsoft Office 2013 (30 days free trial)

for immediate use.- • Labview Based Temperature Control System (EQ-MTS01) enables the user to edit

temperature profile, manage heat-treatment recipe, record and plot data for MTI furnaces. - • A wireless remote control provides up to 300 meters operating range.

- • Above features are available upon request at an extra cost (up to $1,000). Please contact

us for more information. - • Note: The software is only compatible with MTI’s Yudian Temperature Controller

|

Compliance

|

• CE Certified- • NRTL(UL61010) or CSA certifications are available at extra cost.

|

Warning

Click here to learn the installation of a gas regulator

|

• The tube furnaces with quartz tube are designed for use under vacuum and low pressure

<0.2 bars - • Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit

the pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas

regulator. - • Vacuum pressures may only be safely used up to 1000°C

- • The flow rate for gasses should be limited to< 200ml/min) for reducing thermal shocks to the

tube

|

Operation Demo Video & Instructions

|

|