Furnace Structure

|

• Energy saving high purity Al2O3 fibrous insulation liner- • Stainless steel shell with adjustable height

- • Adjust three knobs on the back to flexibly change the furnace's vertical position within travel

distance

(from control box platform to lower end of the chamber): 4.5'' ~ 12'' (without hanger and supporter) - • Multiple configurations for various thermal processing needs

Multi-position adjustable Multi-position adjustable

Using as a Vertical muffle furnace Using as a Vertical muffle furnace

Fixing Knobs for Position Adjustment Fixing Knobs for Position Adjustment

|

Current Rating | 15 Amps |

Power

| 1500W

|

Voltage | AC 110V Single Phase or AC 220V Single Phase can be selected in option bar |

Working Temperature

| |

Heating Rate | Max. Heating Rate: 10°C /min |

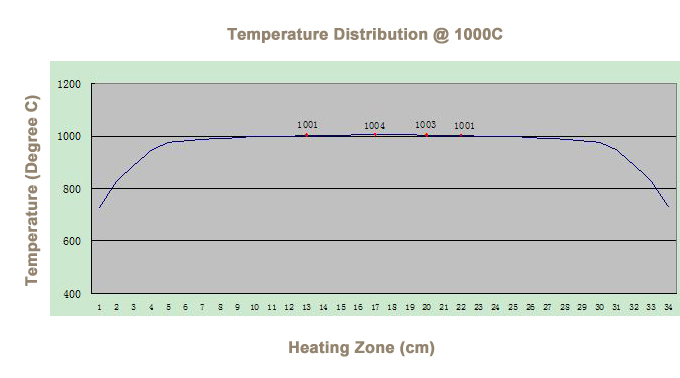

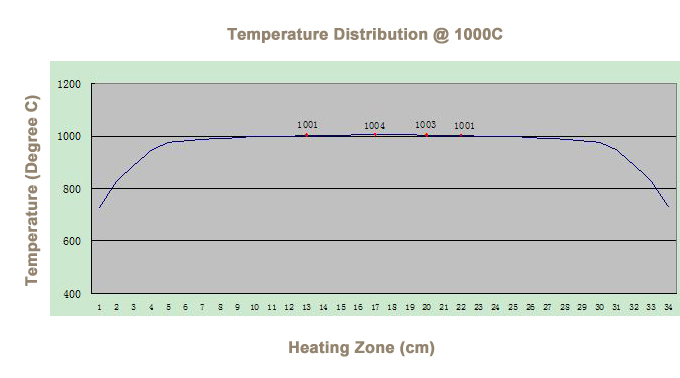

Temperature Distribution |

|

Heating Zone | |

Temperature Controller

|

• PID automatic control and auto-tune function.- • 30 programmable segments for the precise process

- • Built-in protection for overheated and broken Thermal couple.

- • Temperature Accuracy: +/- 1 °C

- • K-type thermal couple

|

Advanced Temperature Controller (Optional)

| |

Heating Elements | Fe-Cr-Al Alloy doped by Mo |

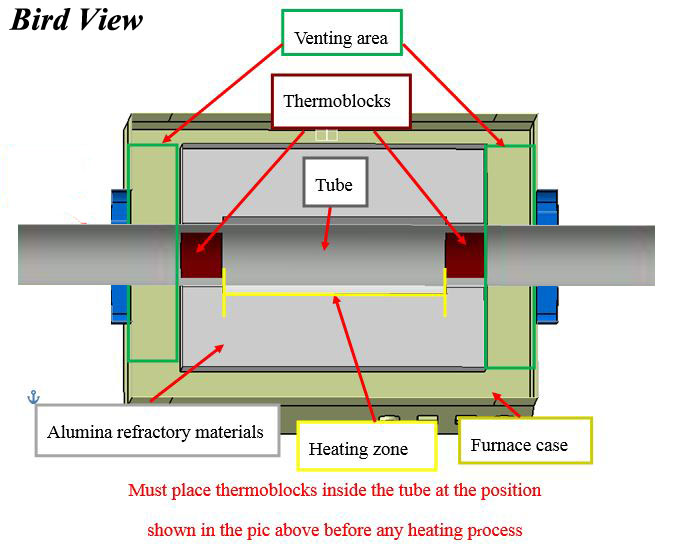

Processing Tube (Sold Separately) & Tube Adapter

|

Two choices of quartz tubes: 25 ODx22 ID x 610 L (mm) quartz tube or 50 ODx44 ID x 610 L (mm) quartz tube (Please find in related products) |

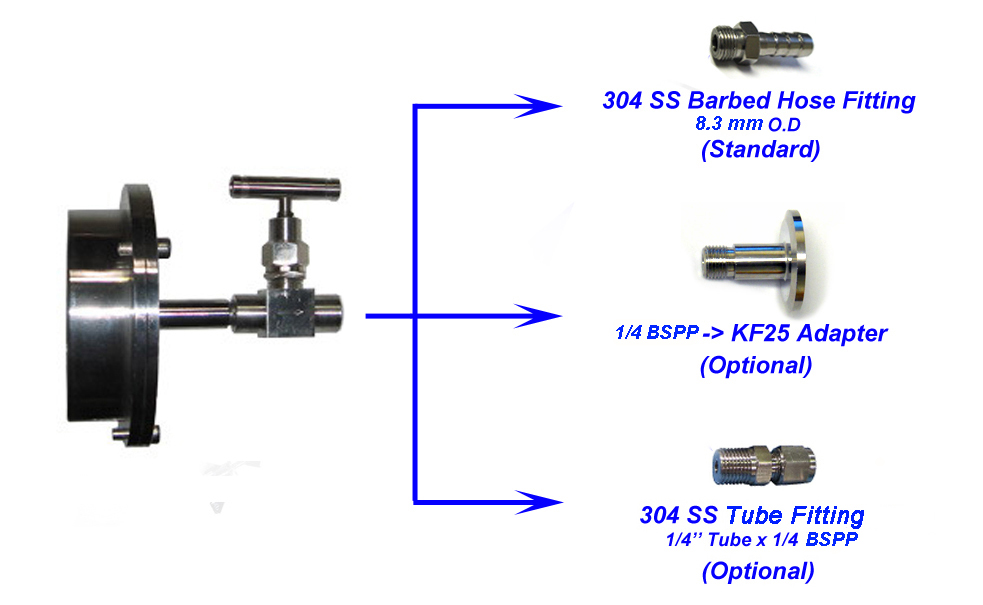

Vacuum Flange

(Sold Separately)

|

Two choices of stainless steel flanges with vacuum gauge and valves

- • 2" flange with 1/4'' tube feedthrough port to insert 1/4" thermocouple

(click bottom right picture to see details ) - • 1" flange has no thermocouple insert ( click bottom left picture to see details )

1" Flange Set 1" Flange Set  2" Flange Set 2" Flange Set

Options: |

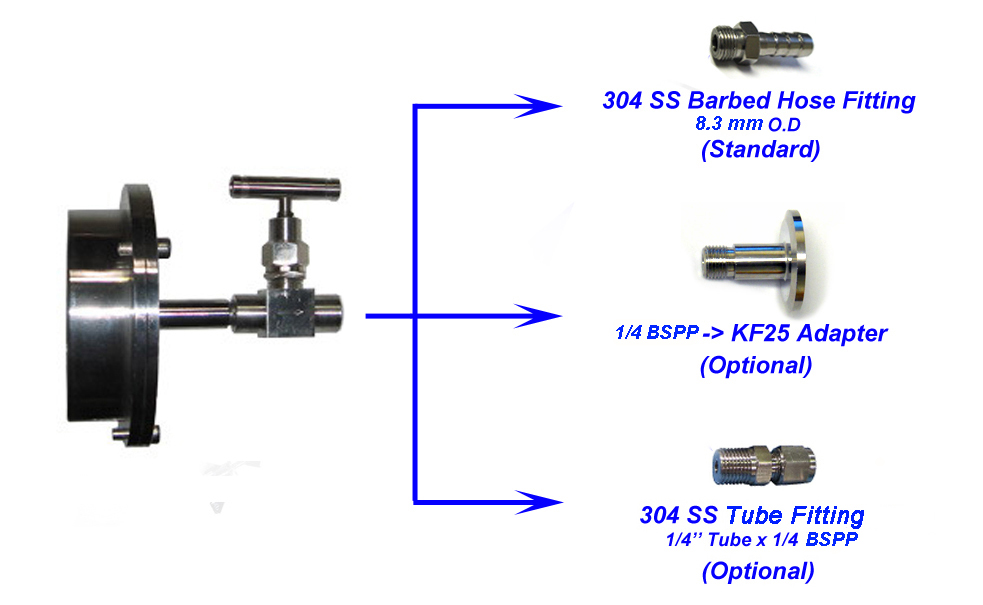

Fitting Ports (Sold Separately)

| |

Vacuum Pressure

|

• Limited by vacuum pump- º 50 mtorr can be achieved by mechanical pump

- º 10^-5 torr can be reached by molecular pump

- •

|

Digital Pressure Gauge (optional)

|

A gas-type independent (above 10mbar) digital vacuum gauge with a wide range between 3.8x10-5 to 1125 Torr. Aside from greater measurement precision, this gauge reduces risks of chamber explosions caused by incorrect reading of gas pressures due to gas-type dependency. (Please click picture left for details)

|

Dimensions

|

260mm(L) x 380mm(W) x 400mm(H) (Click here for details) 260mm(L) x 380mm(W) x 400mm(H) (Click here for details)

|

Shipping Package Dimensions | 40"(L) x 30"(W) x 30"(H) |

Shipping Weight | 80 lbs |

Warranty | One year limited warranty with lifetime support. |

Compliance |

• CE Certified- • NRTL or CSA certification (UL61010 or SPE1000) is available at the extra cost.

|

Application Notes

Click here to learn the installation of a gas regulator

|

• Tube furnaces with quartz tubes are designed for use under vacuum and low pressure

< 0.2 bars / 3 psi / 0.02 MPa

- • Attention: A two-stage pressure regulator must be installed on the gas

cylinder to limit the pressure to below 3 PSI for safe operation.

Click here to learn the installation of a gas regulator. - • Vacuum limit for all quartz tube furnaces is < 1000oC.

- • The flow rate for gases should be limited to< 200ml/min)for reducing thermal shocks to the tube

- • Please click here to see our typical temperature profile calibration results at various temperatures.

- • In order to obtain accurate temperature inside a tube furnace, please click here to learn how to

calibrate the temperature on your own. - • How to set up a ceramic tube and vacuum flange for MTI tube furnaces.

|

Operation Instructions |  |