Furnace Structure

|

• Energy saving high purity Al2O3 fibrous insulation liner- • Stainless steel shells with adjustable height stand

- • Adjust three knobs on the back to flexibly change the furnace's vertical position within travel

distance (from control box platform to lower end of the chamber): 4.5'' ~ 12''

(without hanger and supporter) - • Multiple configurations for various thermal processing needs

Multi-position adjustable Using as a Vertical muffle furnace Fixing Knobs for Position Adjustment

|

Furnace Casing |

• Energy saving high purity Al2O3 fibrous insulation- • Stainless steel shells with adjustable height stand

|

| Power | 1500W |

| Voltage | AC 110V or AC 220V 50/60 Hz -- please select the voltage in the option bar |

Working Temperature | |

| Heating Rate | Max. Heating Rate: 10°C /min |

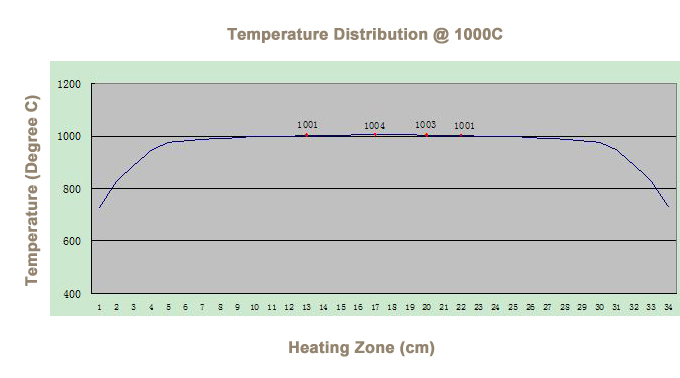

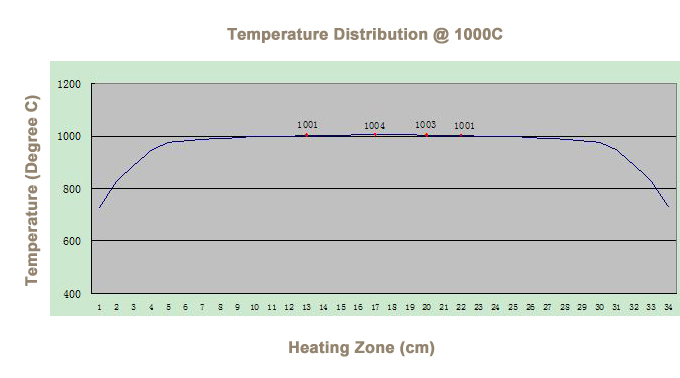

Temperature Distribution |

|

Heating Zone |

• Heating Zone length: 8" (200mm)

- • Constant Temperature Zone: 100mm (+/-1°C @ 1000 °C)

|

Temperature controller |

• PID automatic control and auto-tune function.- • 30 programmable segments for precise process

- • Built in protection for overheated and broken Thermal couple.

- • Temperature Accuracy: +/- 1 °C

- • K-type thermal couple: K type 18" L x 1/4"Dia with Alloy sheath and Male Plug for Caliberation

up to 1335C

|

Temperature Calibrator |

|

| Heating Elements | Fe-Cr-Al Alloy doped by Mo |

Tube Size and Materials |

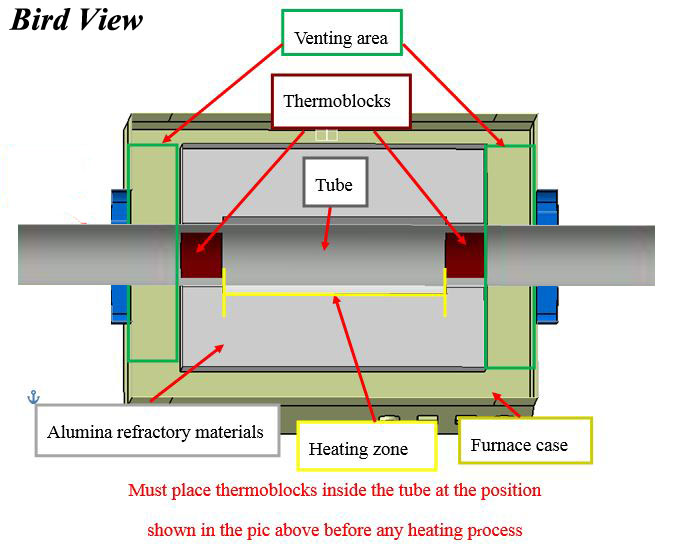

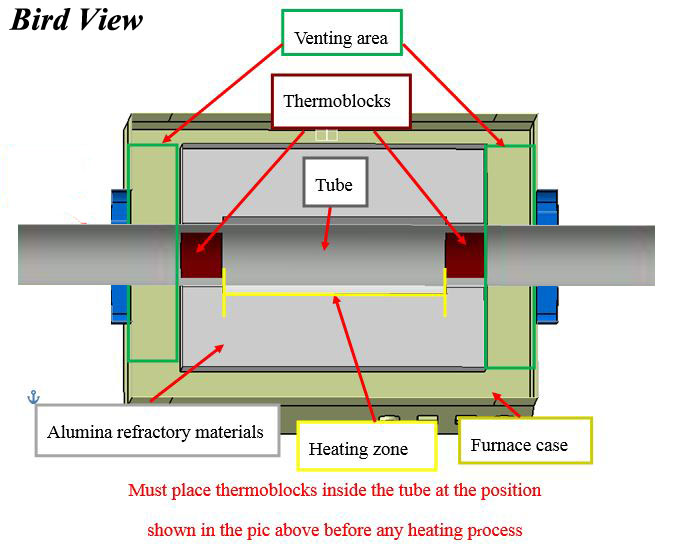

• Quartz Tube with OD: 50; ID 43: Length: 600mm- • Two fibrous ceramic tube blocks are included for blocking heat radiation from inside tube.

(Ceramic blocks must be fully inserted into the furnace chamber before heating) - • Quartz blocks (optional) are ideal for cleaner and higher vacuum efficiency.

click here to choose a crucible

|

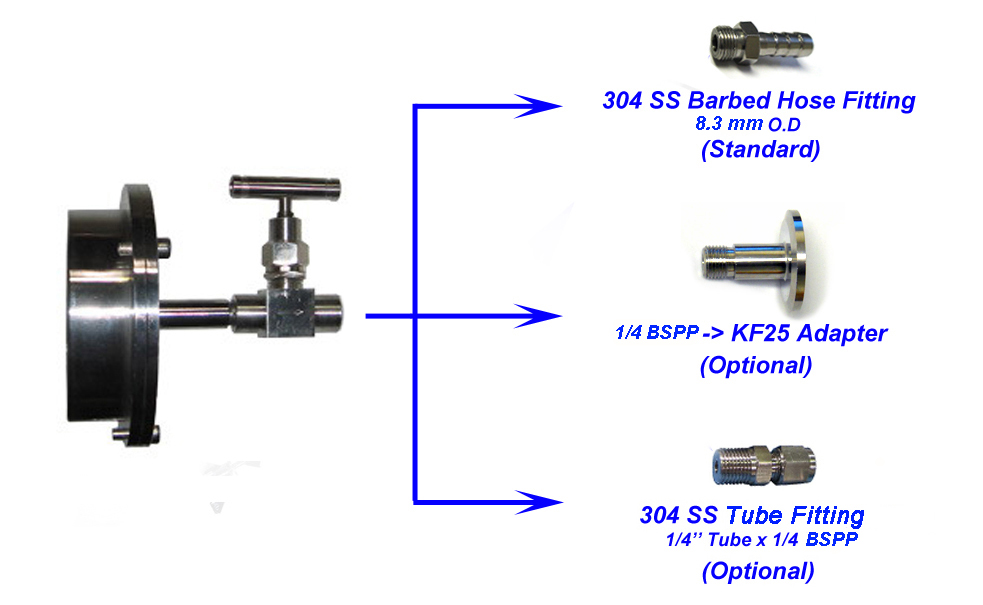

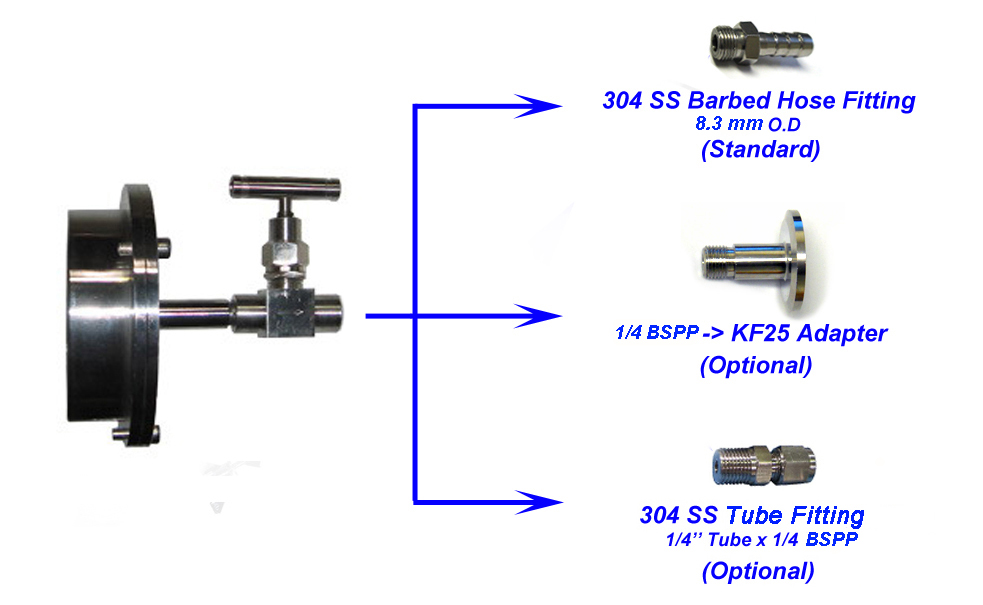

Vacuum Sealing Flanges |

Stainless Steel Vacuum Flanges (Left with 1/4 barb fitting, Digital Vacuum Gauge and Thermocouple feedthrough, right with KF25 port and Right Angle Valve)

|

Fitting Ports

|

• Standard 1/4‘’ Barbed fittings with needle valves.- • For supplying high-pressure gas, you may replace the standard barbed hose fitting with the

304SS 1/4" Swagelok® Tube Fitting, please click underlined to order. - • Optional: In order to increase the throughput and achieve high vacuum, you may replace the

standard barbed hose fitting with the KF25 adapter, please click the underlined to order. - • Optional: You may also consider using the parts in below to increase the vacuum efficiency

|

Vacuum Pump and Vacuum Level |

• Double Stage Rotary Vane Vacuum Pump EQ-FYP-Pump (156L/m) with oil trap, Exhaust Filter,

Bellow& KF-D25 Inlet and KF25 Clamp are included.- • Vacuum Pressure can reach 1E-2 Torr ( 50 m-torr)

- • 10^-5 torr can be reached by molecular pump, click the picture below to order

|

| Dimensions | 10" x 15" x 16" (26 x38 x40 cm) (D x H x W) (Click here for details) |

| Net Weight | 100 lbs |

| Shipping Dimensions | 40"(L) x 26"(W) x 35"(H) |

| Shipping Weight | 180 lbs

|

| Warranty | One-year limited warranty (Consumable parts such as processing tubes and o-rings are not covered by the warranty, please order the replacement at related products below.) |

Compliance |

• CE Certified- • All electric components ( >24V) are UL / MET / CSA certified

- • The furnace is ready to pass TUV(UL61010) or CSA certification at extra cost.

( please click marks below to learn details )

|

Application Notes

Click here to learn the installation of a gas regulator

|

• Tube furnaces with quartz tubes are designed for using under vacuum and low pressure

< 0.2 bars / 3 psi / 0.02 MPa- • Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the

pressure to below 3 PSI for safe operation.

Click here to learn the installation of a gas regulator. - • Vacuum limit definition for all quartz tube furnaces: * Vacuum pressures may only be safely

used up to 1000°C - • The flow rate for gases should be limited to<200 SCCM (or 200ml/min) for reducing thermal

shocks to the tube - • Please click here to see our typical temperature profile calibration results at various temperatures.

- • In order obtain accurate temperature inside tube furnace, please click here to learn how to

calibrate the temperature on your own. - • How to set up tube and vacuum flange for MTI tube furnaces.

|

| Operation Instructions |

|