Furnace Structure

|

The tube furnace has three layers

- 1. Heating Layer: Center alumia tube ( 20OD x 25 ID x 1200 L , mm ) with heating coil

- 2. Vacuum layer: Quartz tube ( 80 mm dia.x 1000 mm L ) with vacuum sealed and flange for thermal insulation

- 3. Water cold layer: outer quartz tube ( 100 mm dia. x1000 mm L ) to keep outside wall < 30ºC

- 4. Outer Tube: 90mm O.D x 58mm I.D

- 5. Inner SiC Sheath: 36mm O.D

customized size tube is available upon request

|

Power

|

• 208 - 240 VAC, single phase - • 2000W

|

Working Temperature

| |

Heating Rate | - • Max. Heating Rate: 10°C /min

|

Heating Zone |

• Heating Zone Length: 1000 mm

- • Constant Temperature Zone: 700 mm within +/- 2oC

|

Temperature Controller

|

• PID automatic control and auto-tune function.- • 30 programmable segments for precise process

- • Built in protection for overheated and broken Thermal couple.

- • Temperature Accuracy: +/- 1 °C

- • K-type thermal couple

|

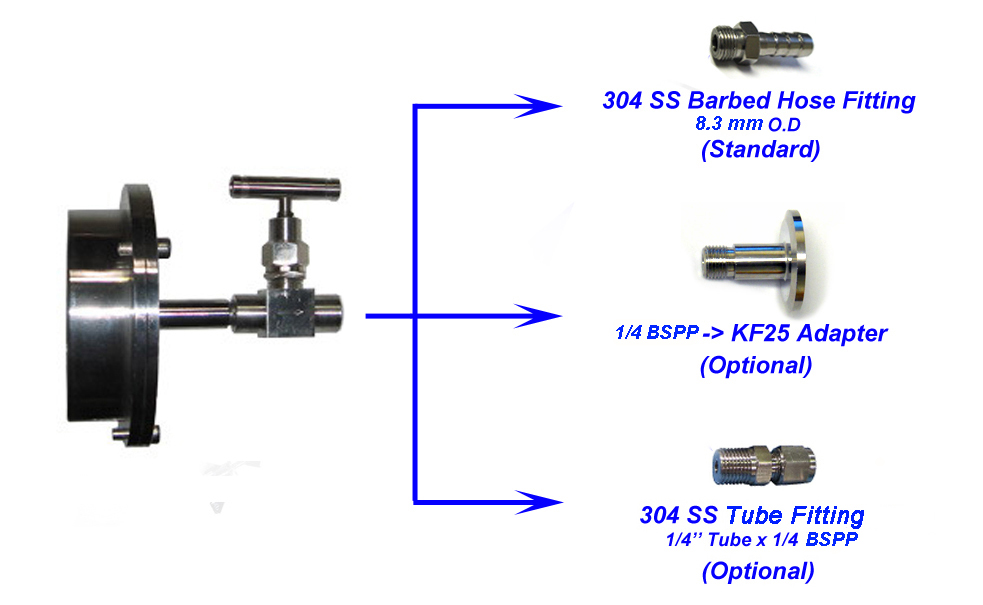

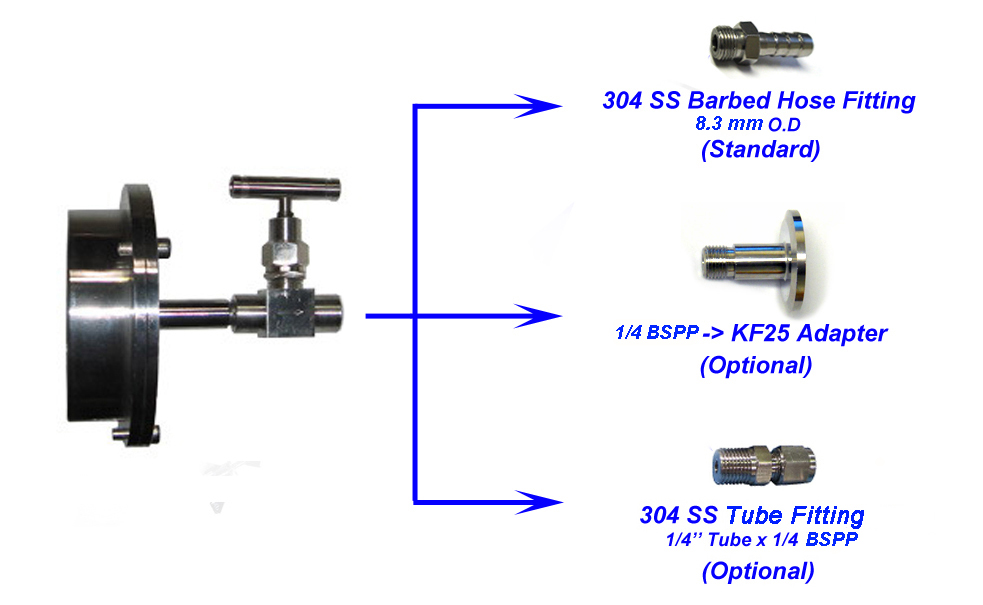

Vacuum Flange

(Sold Separately)

|

• Special flange for three layers tube is included- • 1" flange is included for center tube

-

1" Flange Set 1" Flange Set

|

Fitting Ports (Sold Separately)

| |

Vacuum Pressure

|

• Limited by vacuum pump- º 50 mtorr can be achieved by mechanical pump

- º 10^-5 torr can be reached by molecular pump

- •

|

Digital Pressure Gauge (optional)

|

A gas-type independent (above 10mbar) digital vacuum gauge with a wide range between 3.8x10-5 to 1125 Torr. Aside from greater measurement precision, this gauge reduces risks of chamber explosions caused by incorrect reading of gas pressures due to gas-type dependency. (Please click picture left for details)

|

Shipping Package Dimensions | |

Shipping Weight | |

Warranty | One year limited warranty with lifetime support. |

Compliance |

• CE Certified- • All electric parts are UL / MET / CSA certified

- • The furnace is ready to pass UL or CSA certification (UL61010 or SPE1000) on customer side at customer cost.

|

Application Notes

Click here to learn the installation of a gas regulator

|

• Tube furnaces with quartz tubes are designed for using under vacuum and low pressure < 0.2 bars / 3 psi /

0.02 MPa

- • Attention: A two stage pressure regulator must be installed on the gas cylinder to limit

the pressure to below 3 PSI for safe operation.

Click here to learn the installation of a gas regulator. - • Vacuum limit definition for all quartz tube furnaces: * Vacuum pressures may only be safely used up to 1000°C

- • The flow rate for gases should be limited to<200 SCCM (or 200ml/min) for reducing thermal shocks to the tube

- • Please click here to see our typical temperature profile calibration results at various temperatures.

- • In order obtain accurate temperature inside tube furnace, please click here to learn how to calibrate the

temperature on your own. - • How to set up a ceramic tube and vacuum flange for MTI tube furnaces.

|

Operation Instructions |  |