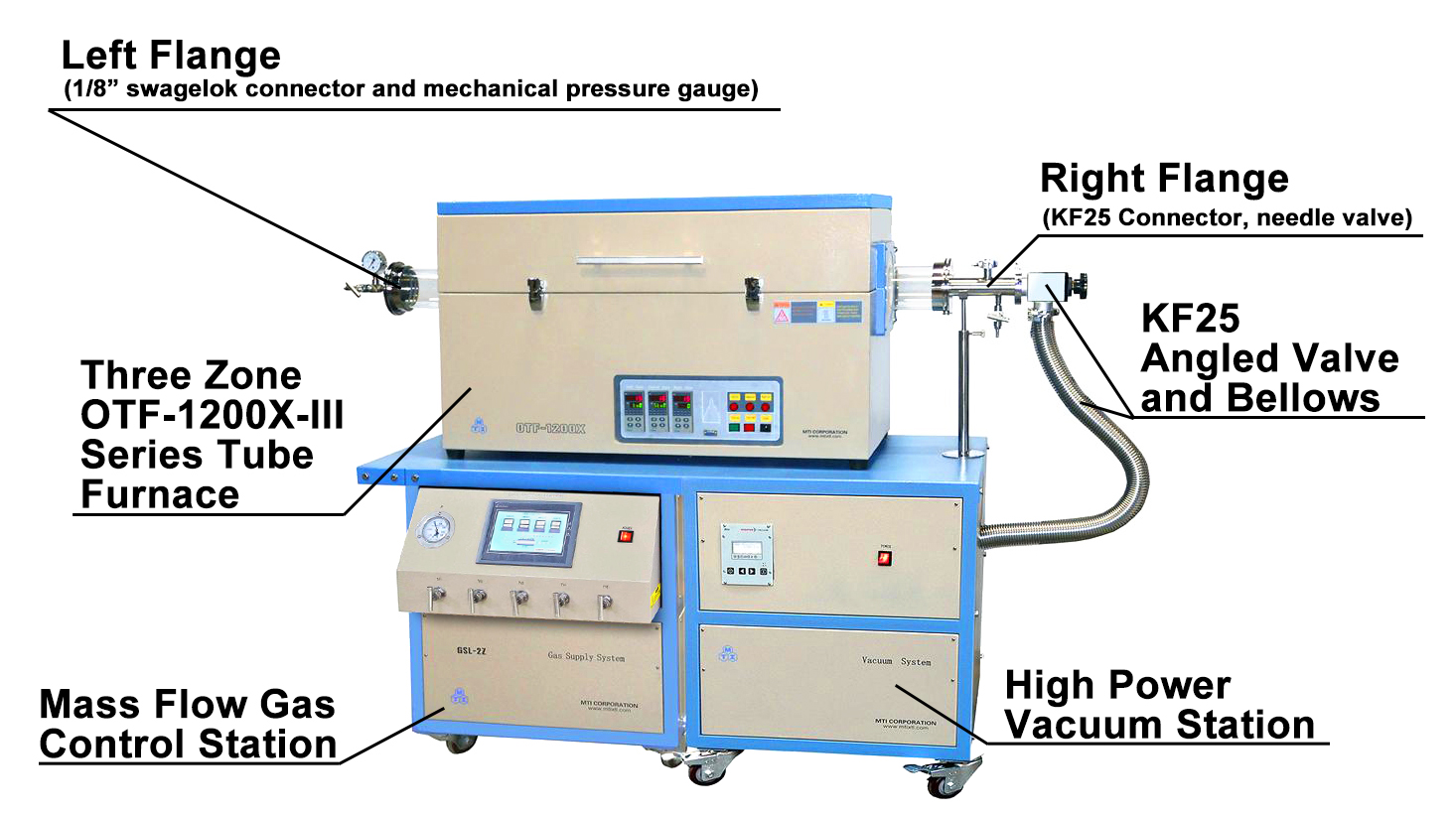

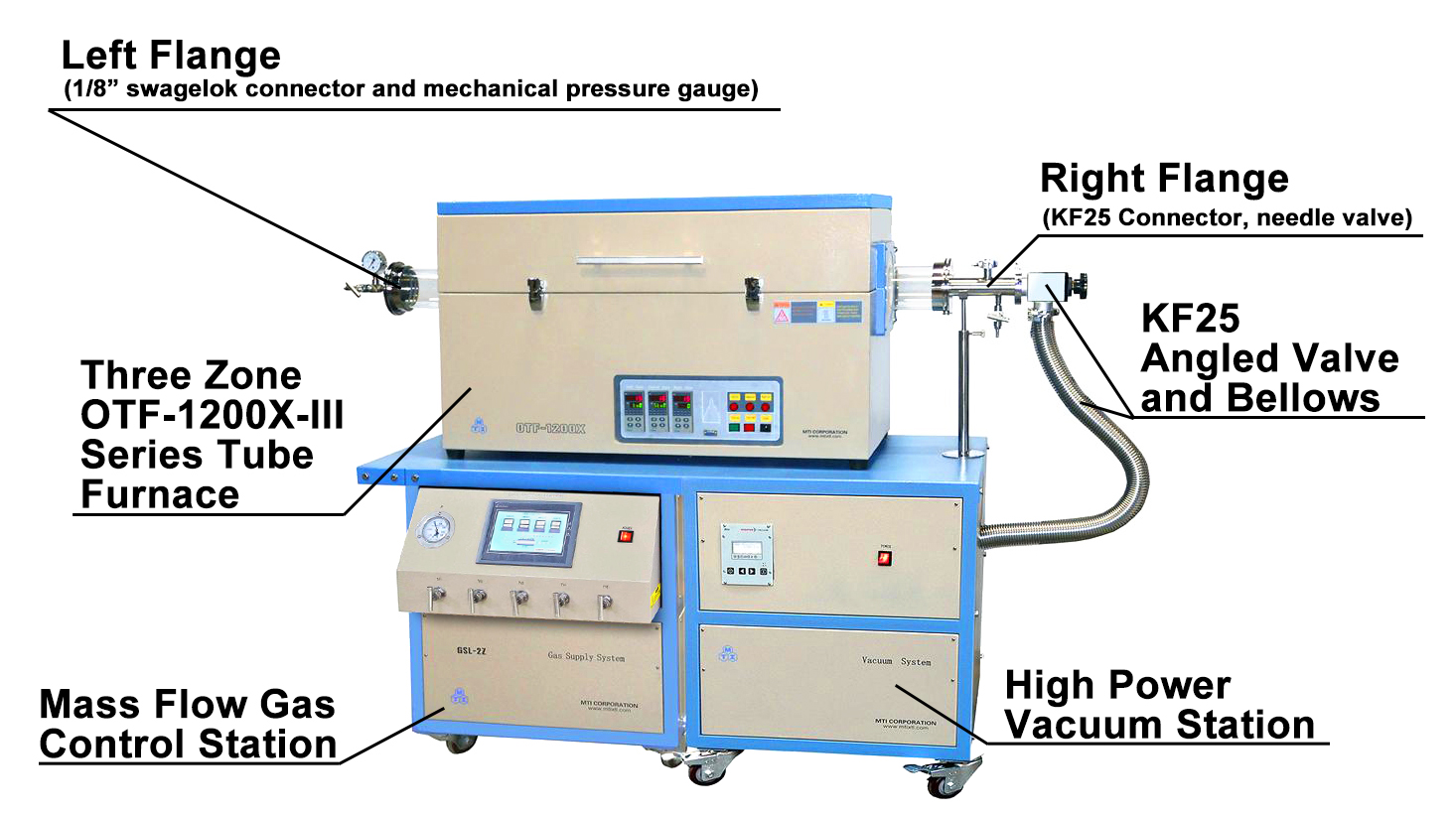

OTF-1200X-III series tube furnace

| Casing

| Double layer steel casing with air cooling.

Built-in thermostat to control Cooling running automatically when case > 55°C.

|

Processing Tube

| Material: Fused quartz tube

One processing tube is included with the furnace.

Please select the tube size in the option bar to update the price.

|

Thermal Block Placement |   click here to choose a crucible click here to choose a crucible |

Power

| 7KW

|

Rated Voltage

| AC 208-240V Single phase, 50/60Hz

|

Heating Element

| Fe-Cr-Al Alloy doped by Mo

|

Working Temp.

| Max. Heating Temp.: 1200°C

Continuous Working Temp.: 1100°C

|

Heat-up Rate

| Heat-up rate: 1~20°C/min programmable

|

Heating Zone Length

| Total heating zone: 900mm (300mm + 300mm + 300mm)

|

Temp. Controller

| - • Three precision temperature controllers to control three

zones separately. - • PID automatic control with 30 steps programmable

segments. - • Temperature accuracy: ±1°C

- • Thermocouple: K type built inside the furnace

|

Vacuum Seal

| One pair of stainless steel vacuum flange with:

- one mechanical pressure gauge

- two needle valves

- one KF-40 connector for the high vacuum station.

|

Rated Voltage

| AC 208-240V Single Phase, 50/60Hz

|

Dimension

| 1100(L) x 450(W) x 670(H), mm

|

High Vacuum Station

| Structure

| Mobile cart size: 600 (L) x 600 (W) x 700(H), mm

Max. Loading: 600 Lbs on top

Molecular pump control Panel : LCD digital

Inside: Pfeiffer vacuum pump made in Germany

Vacuum sensor is included

|

Volume Flow Rate

| Nitrogen N2 33 L/s

Helium He 39 L/s (2340L/minute)

Hydrogen H2 32 L/s

|

| Working Range | From 1000 mbar to <1E-7 mbar |

| Ultimate Pressure | <1E-8 mbar (without any leaking )

|

| Voltage & Power | 110VAC or 220VAC, 110W |

Mass Flow Gas Control

|

Structure

| |

| Power | 18W |

Rated Voltage

| AC 208-240V, Single phase, 50/60Hz

|