GSL-1700X series tube furnace |

Casing

|

Double layer steel casing with air cooling.

Two cooling fans inside to keep case temperature < 55°C.

High purity Alumina refractory chamber

Vacuum and gas mixing system are located in the bottom Mobile cart with 4 wheels.

Vacuum flange, gauge, valves, pipe and high vacuum pump are included for immediate use.

|

Processing Tube

|

Material: High Purity Alumina

One 60mm O.D. processing alumina tube (EQ-TA-60D-M1000) is included with the furnace.

The furnace can be also custom made to fit the 50mm or 80mm O.D. processing alumina tube at an extra cost, please contact us for more information.

|

Thermal Block Placement

|

|

Power

| 6KW

|

Rated Voltage

| AC 208-240V Single phase, 50/60Hz

|

Heating Element

| 8 pcs 1800°C grade MoSi2 heating element

|

Working Temp.

| Max. Heating Temp.: 1650°C

Continuous Working Temp.: 1600°C

|

Heat-up Rate

| <=5°C/min

|

Heating Zone Length

| Heating zone length: 457 mm (18")

Constant Temperature Zone length: 150 mm (6")(+/-1°C)

|

Temp. Control

|

PID automatic control via current limiting phase angle fired the resistor with 30 steps programmable segments.

Temperature accuracy:±1°C

Thermocouple: B type built inside the furnace

RS485 Communications Port.

- • Advanced Temperature Control (Optional)

- • MTS02-Y Temperature control software kit (for YD518P series controllers) +

15" laptop package is available at the options bar. Click for the detail

information about the MTS02-Y software kit. - • You may upgrade the temperature controller to the Eurotherm 3504

Temperature Controller which is fully compatible with LabVIEW. This package

includes a Eurotherm 3504 programmer, a communication cable (RS485 -

USB) and a software CD. Click the pic below to view the full spec of Eurotherm

3504 temperature controller.

|

Vacuum Seal

|

One pair of stainless steel vacuum flange with:

- one mechanical vacuum gauge

- two needle valves

- one KF-25 connector and KF-25 to KF-40 adapter for the high vacuum station.

- one 1/4" Swagelok tube connector

|

Dimension

| 550 x 380 x 520 |

High Vacuum Station

| Power

| 100~110W

|

Rated Voltage

| AC 208-240V Single Phase, 50/60Hz

|

Dimension

| 600(L) x 600(W) x 700(H), mm

|

Structure

|

Mobile cart size: 600 (L) x 600 (W) x 700(H), mm

Max. Loading: 600 Lbs on top

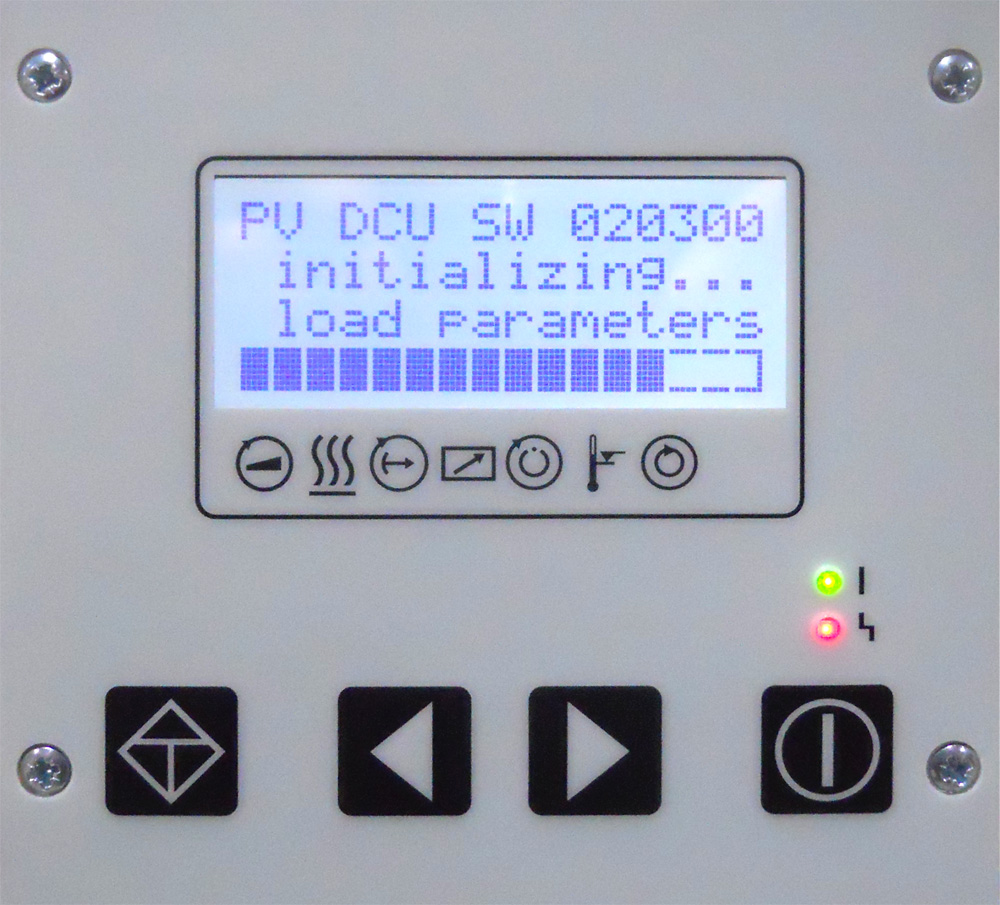

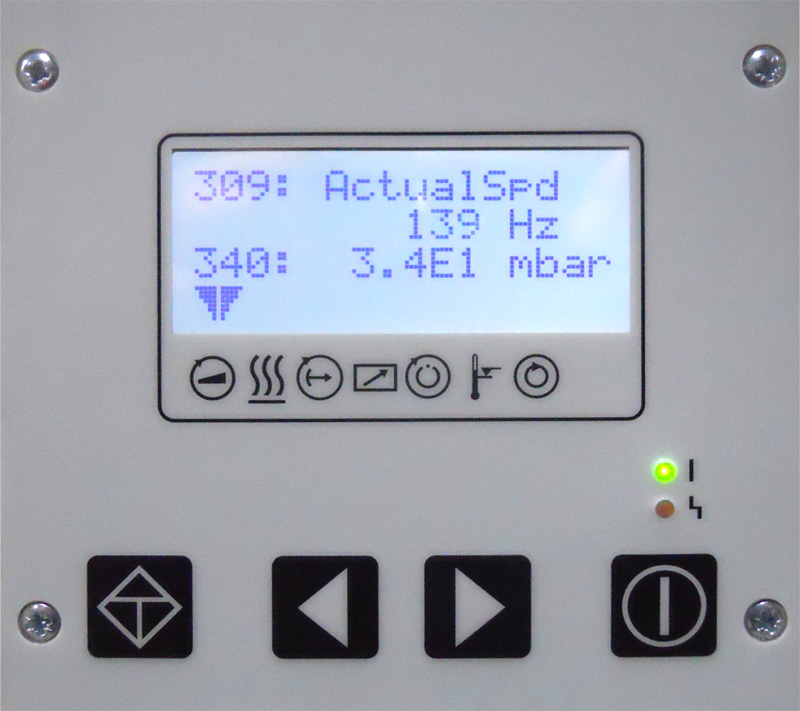

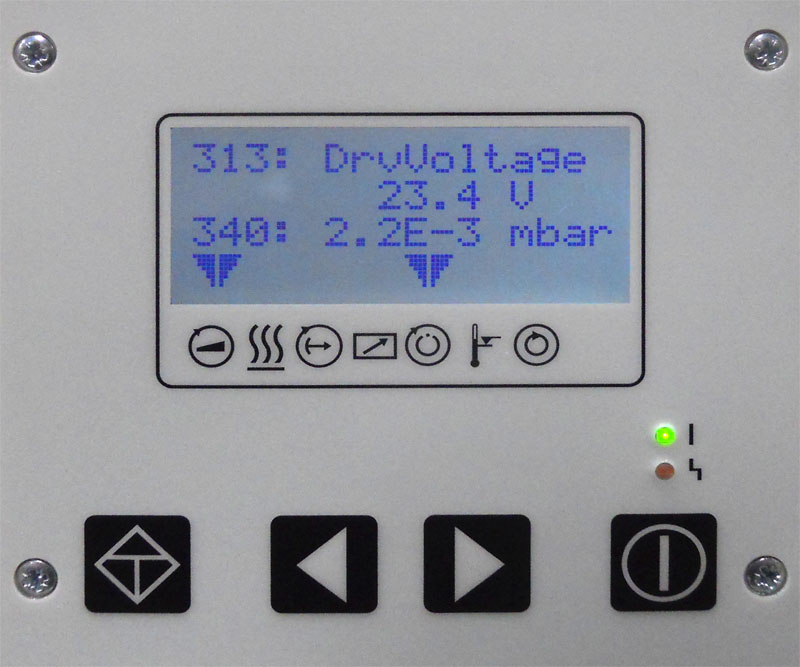

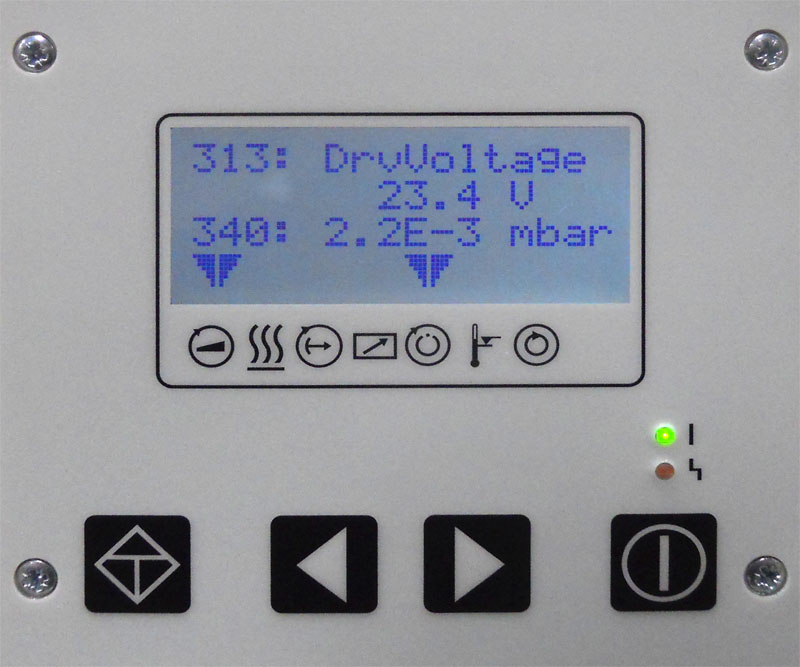

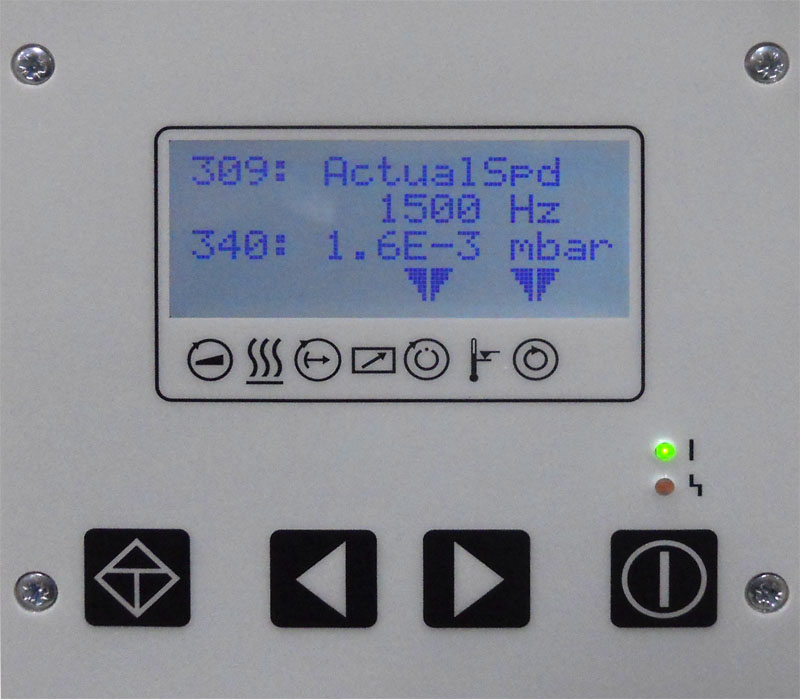

Molecular pump control Panel : LCD digital

Inside: Pfeiffer vacuum pump made in Germany

Vacuum sensor is included

|

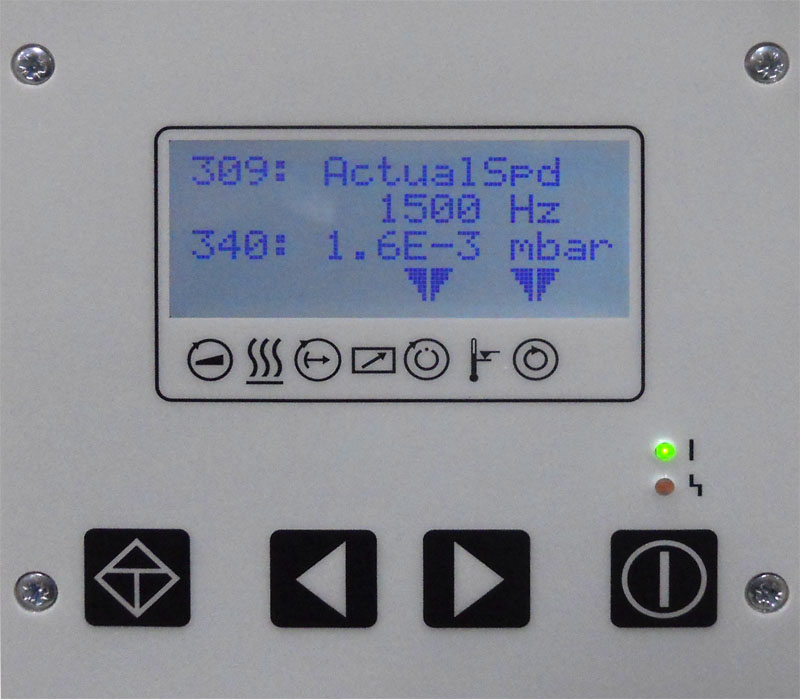

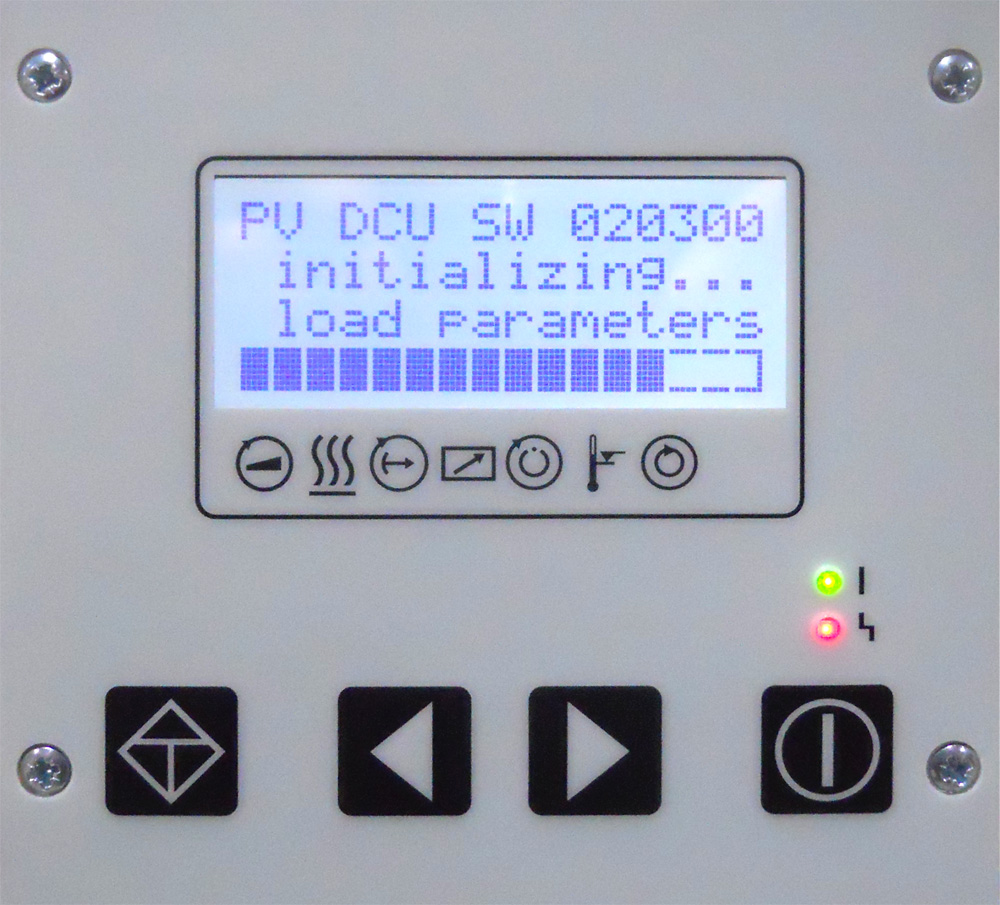

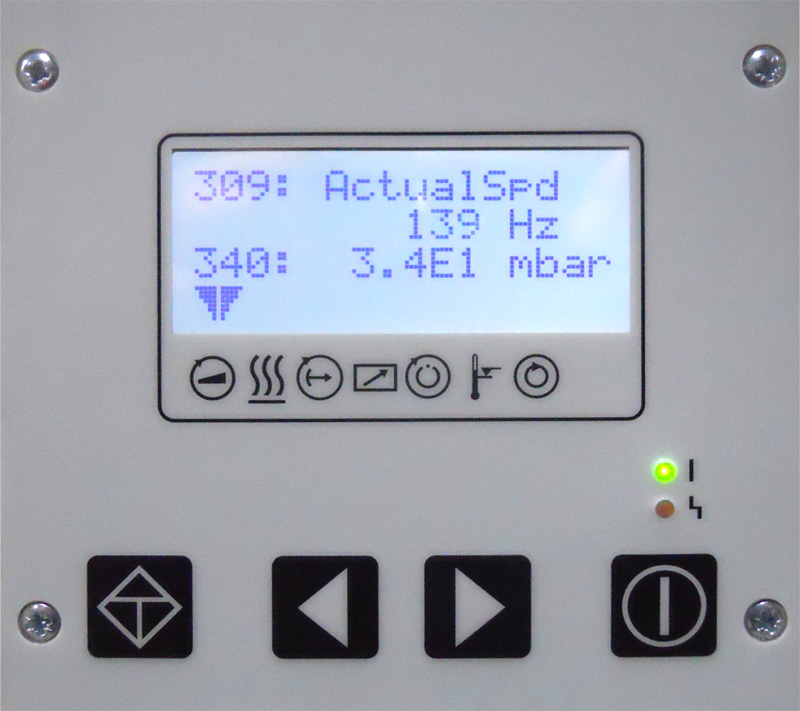

Control Panel

|

One button operation - the diaphragm pump and the turbo molecular pump will start after pressing "start" button.

System controlled spinning speed - the controller will control the speed of the turbine spinning up and down according to the vacuum level and leaking rate of the reaction chamber.

Self protection - the system will protect the pump from damage by overheating and over-current if the leaking rate of the reaction chamber is too high to achieve high vacuum.

LCD screen - double lines parameters checking interface make the working easier to be handled.

|  |  |  |  | Self testing

| Spinning up | Error report

| Volt meter

| Full speed |

|

Volume Flow Rate

|

Nitrogen N2 33 L/s

Helium He 39 L/s (2340L/minute)

Hydrogen H2 32 L/s

|

| Working Range | From 1000 mbar to <1E-7 mbar |

| Ultimate Pressure | <1E-8 mbar (without any leaking ) |

Mass Flow Gas Control

EQ-GSL-LCD

|

Structure

|

Made of 316 stainless steel valve

Gas mixing tank: Φ80X120mm

600mm(L) x 745mm(W) x 700mm(H)

6" color touch screen control panel to make parameter setting at easy.

Touchscreen Control and PC remote switchable.

The flow rate control range and number of gas routes are available for customization. Please contact us for detail information.

|

| Power | 23W per channel |

Rated Voltage

| AC 220V/50Hz Single phase |

Gas routes

| Please select the number of gas routes in the optional bar to update the price

|

Application Notes

| |

| Warranty | One year limited warranty (Consumable parts such as processing tubes, o-rings and heating elements are not covered by the warranty, please order the replacements at related products below.) |

Compliance

|

• CE Certified- • All electric components ( >24V) are UL / MET / CSA certified

- • The furnace is ready to pass TUV(UL61010) or CSA certification at extra cost.

(please click marks below to learn details)

|

Shipping Dimensions

| Two cases in one plastic pallet: 45x45x35/case

|

Warnings

Click here to learn more about the installation of a gas regulator. |

• The tube furnaces with alumina tube are designed for using under vacuum and low pressure

< 0.02 MPa / 0.2 Bar/ 3 PSI - • Attention: A two stage pressure regulator must be installed on gas cylinder to limit the

pressure to below 3 PSI for safe operation.

Click here to learn the installation of a gas regulator. - • Never heat the furnace while the gas release valve is closed and a positive pressure condition

exists within the furnace chamber. The pressure gauge must be used to closely monitor the

chamber condition at all times during the heating process; please open the gas release valve

immediately once the chamber pressure has reached over 3 PSI to prevent unforeseeable

damages. - • The flow rate for gases should be limited to < 200 SCCM ( or 200ml/min )

- • Vacuum limit definition for all alumina tube furnaces: * Vacuum pressures may only be safely

used up to 1500°C

|

Operation Instructions

|

|