Furnace structure

|

• Double layer steel case with two cooling fans, which ensure low surface temperature- • High purity fibrous alumina insulation for energy saving

|

Power

|

• 9 KW- • Require 60A Air breaker switch

|

Voltage | - • AC 220-240 Single Phase, 50/60 Hz

|

Heating Zone Length

|

• Two zones heated separately- º Zone 1: working temperature 800 - 1500ºC (heated by SiC ), length: 12" (300 mm)

- º Zone 2: working temperature 800 - 1500ºC (Heated by MoSi2) heating 12" (300 mm)

- • Constant temperature zone length: 14" within +/-2ºC ( if two zone setting at same temperature )

- • Max. Heating rate: 10ºC/min

|

Mullite Tube Size

|

GSL-1500X-II-50

50.8 mm O.D. x 44.5 mm I.D

x 1000 mm Length

|

GSL-1500X-II-75

76.2 mm O.D. x 70mm I.D

x 1000 mm Length |

GSL-1500X-II-100

102mm O.D. x 92mm I.D

x 1000 mm Length |

Tube and Flange

|

• Mullite Tube made in the USA, which has much better thermal shock resistance than Alumina tube.- • Stainless steel vacuum sealing flange with valve and meter is included

- • Thermal block is included . See picture below middle how to place

- • You may order flange support to avoid tube rotating ( click Pic below right )

.jpg)

click here to order spare

|

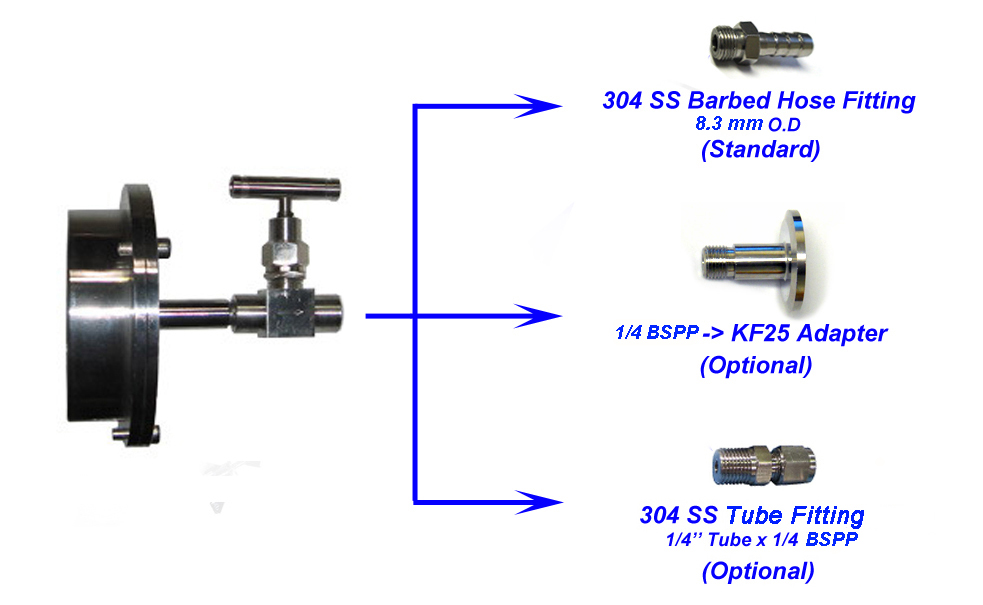

Fitting Ports

|

• In order to increase the throughput and achieve high vacuum, you may replace the standard barbed

hose fitting with the KF25 adapter, please click underline to order. • For supplying high-pressure gas, you may replace the standard barbed hose fitting with the VCR Face

Seal Fitting, please click underline to order.

|

Temperature Control

|

• PID automatic control via SCR (Silicon Controlled Rectifier) power control - • 30 programmable segments for precise control of heating rate, cooling rate and dwell time.

- • Built-in over temperature alarm and protection allows for operation without the attendant.

- • +/- 1 ºC temperature accuracy.

|

Heating Elements

|

• Zone one: 8 pcs U type SiC rods (1500C grade )- • Zone two: 8 pcs U MoSi2 rods (1800C grade )

|

Power cable & plug |

• 10 feet length 8-3 AWG heavy duty UL approved power cable is included- • Extra length cable can be ordered by click picture below

- • The plug is not included. You can order from your local hardware store according to female plug in

your lab, or order from link below (50A plug)

|

Dimension | 780 L x 450 W x 720 H mm |

Net Weight | 150 kg |

Warranty

|

One-year limited warranty (Consumable parts such as processing tubes, o-rings and heating elements are not covered by the warranty, please order the replacement at related products below.)

|

Laptop, software & WiFi Control(Optional)

|

• Brand new laptop with Microsoft Window 10 and Microsoft Office 2013 (30 days free trial) for

immediate use.

- • Labview Based Temperature Control System (EQ-MTS01) enables user to edit temperature

profile, manage heat-treatment recipe, record and plot data for MTI furnaces.

- • A wireless remote control provides up to 300 meters operating range.

- • Above features are available upon request at an extra cost (up to $1,000). Please contact us

for more information.

- • Note: The software is only compatible with MTI’s Yudian Temperature Controller.

- • Eurotherm precision temperature controller with +/-0.1°C accuracy is available upon request

at the extra cost.

|

Certificate |

• CE Certified- • NRTL / CSA Certification is available upon request, additional charges will apply

-

|

Shipping package size | 47" x 45" x 45"(1200L x 1150W x 1150Hmm) |

Shipping weight | 396 Lbs |

Notice | How to set up ceramic tube and vacuum flange for MTI Tube furnace |

Warnings

Click here to learn the installation of a gas regulator.

|

• The tube furnaces with alumina tube are designed for using under vacuum and low pressure < 0.2 bar

/ 3 psi / 0.02 Mpa.

- • Never use graphite crucible in alumina tube.

- • Vacuum pressures may only be safely used up to 1000°C. The flow rate for gases should be limited to

< 200 SCCM (or 200 ml/min) for reducing thermal shocks to the tube.

- • Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the

pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

- • Never heat the furnace while the gas release valve is closed and a positive pressure condition exists

within the furnace chamber. The pressure gauge must be used to closely monitor the chamber

condition at all times during the heating process; please open the gas release valve immediately

once the chamber pressure has reached over 3 PSI to prevent unforeseeable damages.

|

| Operation Instructions |  |

.jpg)