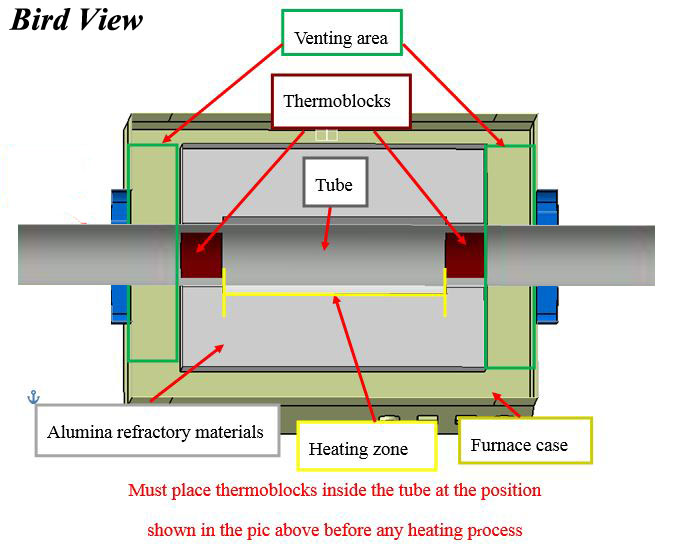

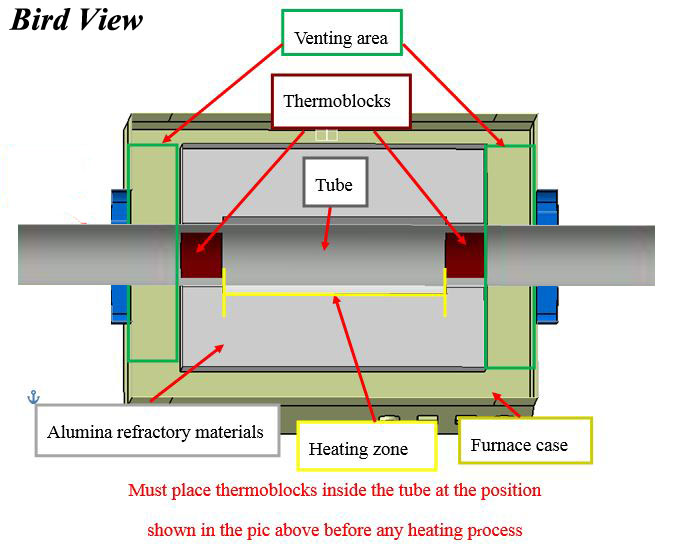

Furnace structure | |

Power & Voltage

| |

Max. Temperature | 1200 oC |

Continuous Temperature | 1100 oC |

Max. Heating Rate | <= 20 oC /min |

Thermal Block Placement

|

|

Heating Zone

|

• Five independent heating zones:

• Each heating zone length of 152 mm • Total heating zone length: 760 mm, ( nominal 800 mm L considering spacer ) - • Max. Constant temperature zone 25" ( 635mm ) if 5 zone heated at same temperature ( within +/- 2oC)

|

Temperature Controllers

|

• PID automatic control with 30 programmable segments for precise control of heating rate, cooling rate and

dwell time.- • Built-in overheating & broken thermocouple protection.

- • Over-temperature protection and alarm allows for operation without attendant(s).

- • +/- 1 ºC temperature accuracy.

- • Five K-type thermocouples (one for each zone).

- • RS485 Communications Port.

- • Optional:

- º The furnace may be operated by PC by installing five control modules. Please order the MTS-02

control modules at extra cost. - º If you order the PC control module together with the furnace, we will install and test it before shipping.

We recommend you to order a computer laptop from us to avoid software installation problems.

For more information please click here.

|

Optional Processing Tube

& Vacuum flange |

• The furnace can accept quartz or mullite tube with diameter 1" - 4“ diameter and minimum length 1400mm

( 55"), which is not included in the package. Please click the picture below right to order tube & tube adapter,

as well thermal blocks

( Note: To accept 5" Dia tube, customer needs to contact MTI tech. the support team for details)

|

Product Dimension

| - • Furnace:1035mm (L)x 385mm (W)x 370mm (H)

- • Control box: 500mm (L)x 490mm (W)x 250mm (H)

|

| Net Weight | About 85 Kg |

Warranty |

• One year limited warranty for electrical parts.- • (Consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty,

please order the replacement at related products below.)

|

Laptop, software & WiFi Control(Optional) | |

Compliance |

• CE Certified

• All electric components ( >24V) are UL / MET / CSA certified

• The furnace is ready to pass TUV(UL61010) or CSA certification at extra cost.

(pls click marks below to learn details )

|

Shipping Weight & Dimensions |

• 385 lbs

• 55"x40"x41

|

Options (click picture to order at extra cost) |

|

Notice |

• How to set up the ceramic tube and vacuum flange for MTI Tube furnace.

• In order to obtain accurate temperature inside tube furnace, you need to calibrate temperature by

yourselves. Please click here to learn how.

|

Operation Instruction

|

|

Application Note

|

• The tube furnaces with quartz/mullite tube are designed for using under vacuum and low pressure

<0.2 bars / 3 psi / 0.02 MPa

• Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the

pressure to below 3 PSI for safe operation. Click here to learn the installation of a gas regulator.

• * Vacuum pressures may only be safely used up to 1000°C

• The flow rate for gasses should be limited to<200 SCCM (or 200ml/min) for reducing thermal shocks

to the tub

|