Furnace Structure

|

• Double layer steel structure with air cooling to keep case temperature < 65oC.- • Vertical and splittable for easy installation.

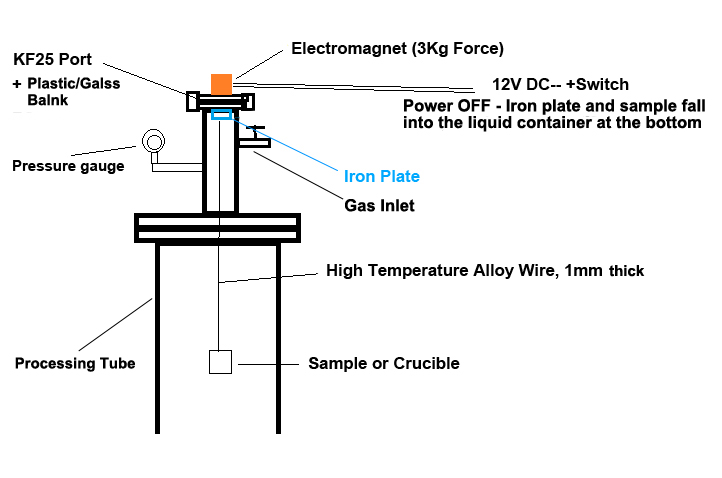

- • The tube is sealed by a gate valve at the bottom flange. For quenching, open the gate valve and let the sample drop

directly into the liquid container by activating the electromagnetic sample release.

- • Operation control made easy with a newly designed electric gate valve.

- • Electromagnet sample release flange with water cooling is included.

|

Input Power

|

• AC 208-240V Single Phase, 50/60 Hz- • 6 KW (40A Breaker)

|

Heating Temperature

|

• 1500oC < 30 minutes- • 1400oC < continuous

|

Max. Heating Rate | |

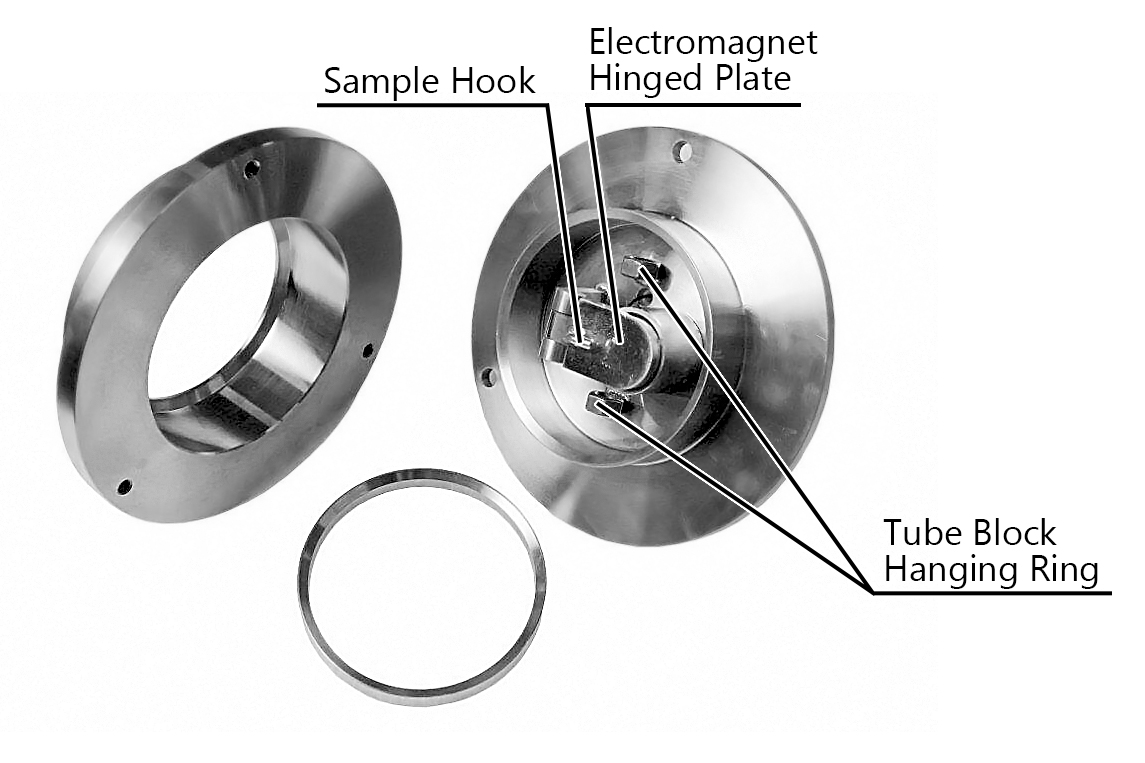

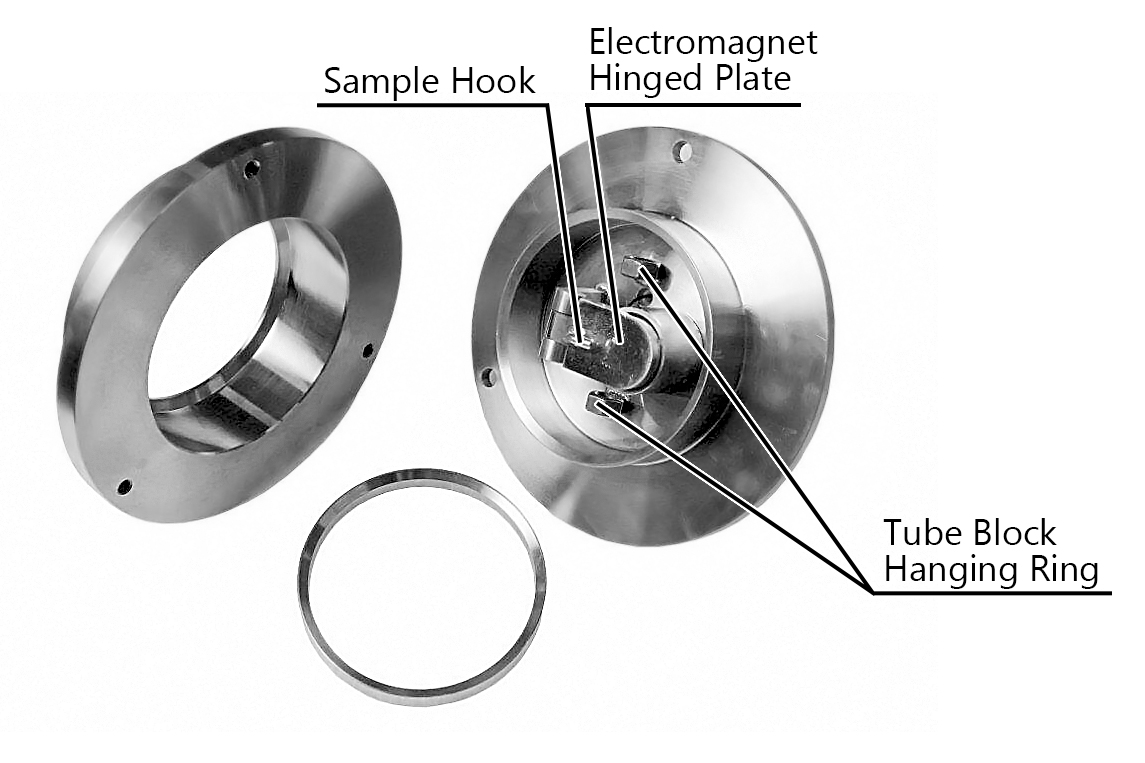

Electromagnet Sample Release Flange

&

Quenching Media Tank

|

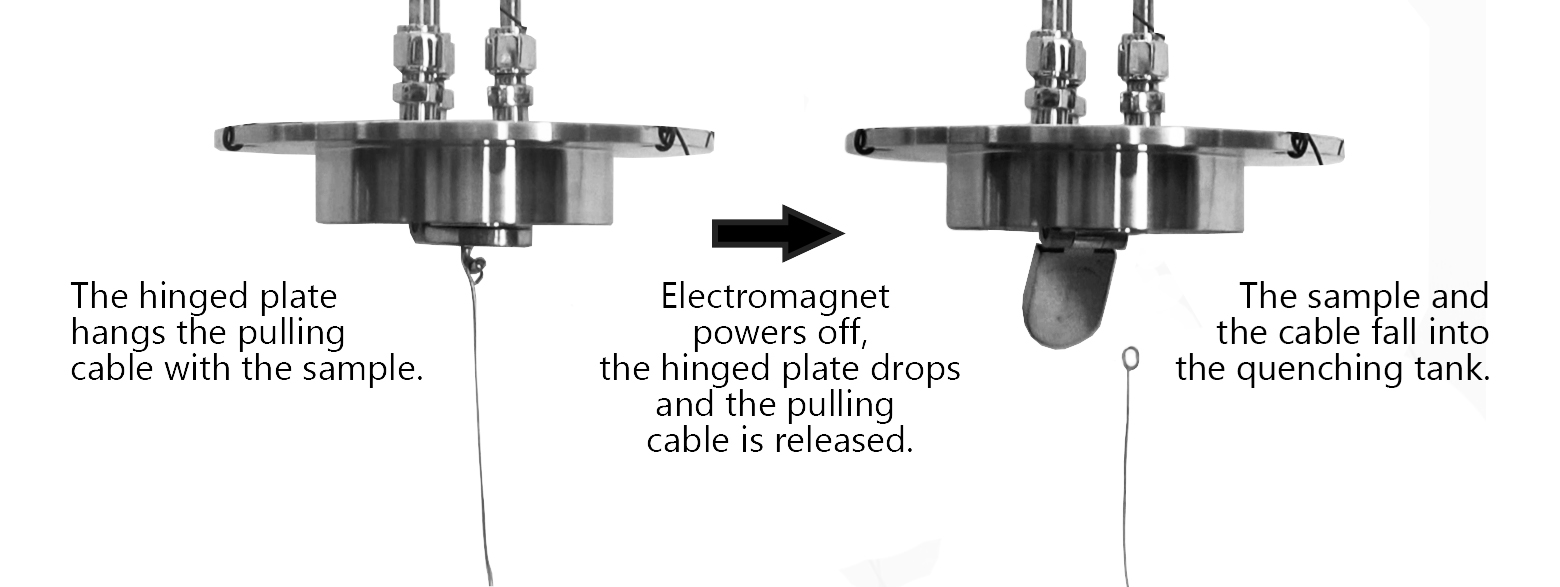

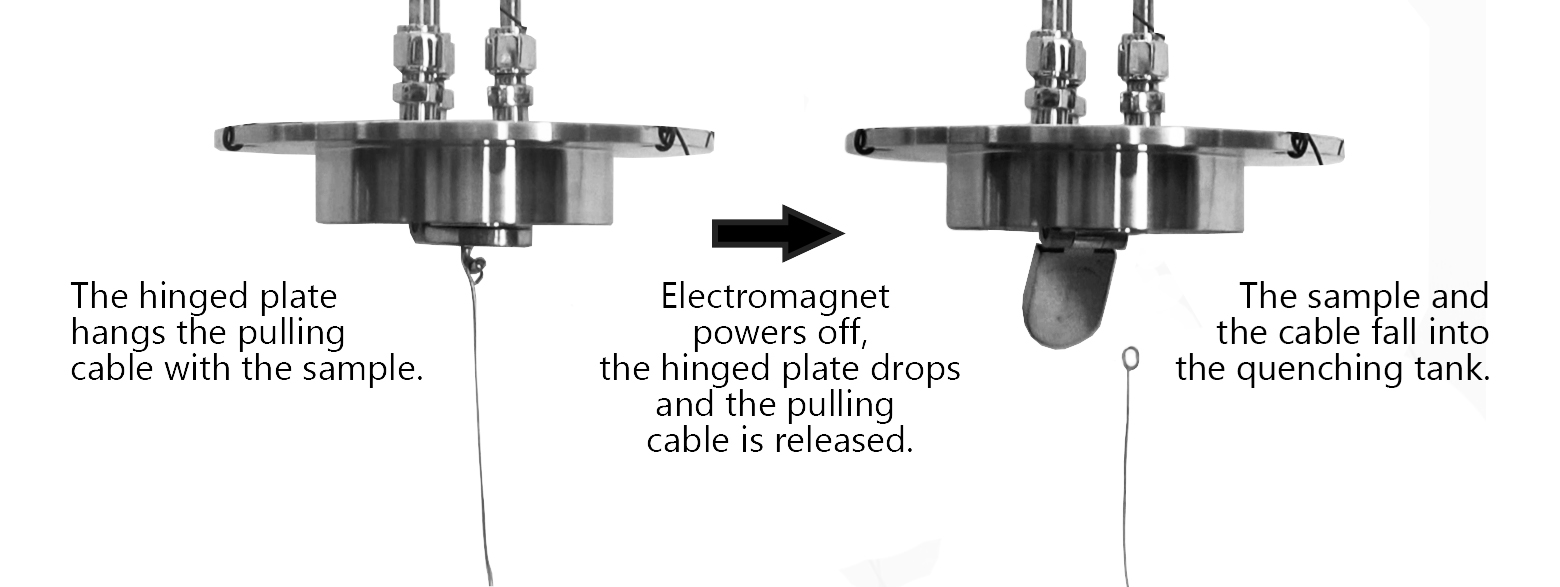

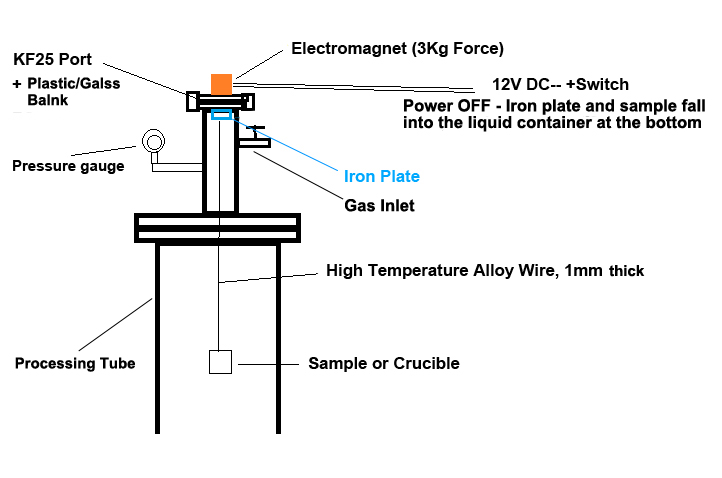

• Fully automatic electromagnet sample release flange.- • Hinged plate hooks the cable, which pulls the sample.

- • Hinged plate drops when the electromagnet powers off. The sample and the cable fall into the quenching tank.

- • Rings are available for hanging the tube block with cables.

- • Improved top flange design allows easy sample reload without uninstalling all parts of the flange.

- • Bottom flange is connected with a 4" gate valve ( electrically operated ) via CF-100 adaptor.

- • The gate valve is connected with a quenching media container in size 400 L x400 W x 200 H mm.

- • Caution: You must use ice water or cooled oil as quenching agent if quenching under vacuum.

|  |  |  |  |  | | 1. Flange Structure | 2. Flange Operation | 3. Gate Valve | 4. Quenching Tank | 5. Quenching | 6. Pulling Cable |

- • Compared to electromagnet cable drop quenching, traditional approach (Cable Cut Quenching) consumes cables.

|  | | Trad. Quenching in Air | Trad. Quenching in Vacuum |

|

Heating Element

|

• 1500°C grade SiC---12 pcs

|

Tube Size and Materials

|

• Mullite tube made in the USA- • OD:82 mm x ID 73:mm x Length: 1000 mm (included)

|

Heating Zone

|

• Heating Zone length: 440 mm - • Constant Temperature: 150 mm ( within+/- 1oC)

|

Temperature Controllers |

• 30 programmable segments for precise control of heating rate, cooling rate and dwell time.- • Built-in PID Auto-Tune function with overheating & broken thermocouple broken protection.

- • Over-temperature protection and alarm allow for operation without attendant(s).

- • +/- 1 ºC temperature accuracy.

- • Five K-type thermocouples (one for each zone).

- • RS485 Communications Port.

- • PC controlled software and interface module are optional. Please select the package option.

|

Temperature controller (optional)

|

• MTS02-Y Temperature control software kit (for YD518P series controllers) + 15" laptop package is available at the options bar.

Click for the detail information about the MTS02-Y software kit.

- • You may upgrade the temperature controller to the Eurotherm 3504 Temperature Controller which is fully compatible with LabVIEW.

This package includes a Eurotherm 3504 programmer, a communication cable (RS485 - USB) and a software CD.

Click the pic below to view the full spec of Eurotherm 3504 temperature controller.

|

Water-Cooled Flanges

|

• Both top and bottom flanges have water-cooling jacket (See left picture), which cools and preserves the O-ring sealings

on the flange during high-temperature operation- • Please click the picture below to order water chiller at an extra cost

|

Vacuum Level

|

• 0.05 torr (by the mechanical vacuum pump)- • Click Picture below to order vacuum pump separately

|

Power Cable & Plug

|

• 10 feet length 10-3 AWG heavy duty UL approved power cable is included. Extra length cable can be ordered by

click picture below-left- • The plug is not included. Browse our catalog for compatible plugs or obtain one from a local hardware store.

|

Dimension

|

1040 L × 510 W × 1900 H ( mm ) 1040 L × 510 W × 1900 H ( mm )

|

Net Weight | - • About 85 kg (excluding mobile cart)

|

Shipping weight & Dimensions

|

• Two Pallets- • 600 lbs, 48"x40"x76"

- • 200 lbs, 48"x40"x27"

|

Warranty

| |

Laptop, software & WiFi Control (Optional)

| |

Compliance

|

• CE Certified- • All electric components ( >24V) are UL / MET / CSA certified

- • The furnace is ready to pass NRTL certification (UL61010) or CSA certification at extra cost.

|

Application Notes

Click here to learn more about the installation of a gas regulator.

| - • The tube furnaces with mullite tube are designed for using under vacuum and low pressure < 0.02 Mpa / 0.2 Bar/ 3 PSI

- • Never use graphite crucible in the alumina tube.

- • Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to below 3

PSI for safe operation. Click here to learn the installation of a gas regulator. - • Never heat the furnace while the gas release valve is closed and a positive pressure condition exists within the furnace chamber.

The pressure gauge must be used to closely monitor the chamber condition at all times during the heating process;

please open the gas release valve immediately once the chamber pressure has reached over 3 PSI to prevent unforeseeable

damages. - • The flow rate for gasses should be limited to < 200 SCCM ( or 200ml/min )

- • Vacuum limit definition for all mullite tube furnaces: * Vacuum pressures may only be safely used up to 1300°C

|

Operation Instructions

|

|