System Structure |

• Air-tight joint between the four furnace tubes and glove boxto protects the sample from oxidation in the preparation.- • Vertical loading of four samples inside the glove box. An electromagnetic release mechanism from top flange can release the sample into the quenching chamber at the bottom.

- • Electric gate valve at the bottom of the tube can isolate the heating chamber from the quenching chamber and open for sample drop when quenching is needed.

- • Both Electromagnet sample release flange and the bottom gate valve are with water cooling jackets which help protect Viton sealing gaskets from over-heated.

|

Input Power

|

• AC 208-240V Single Phase, 50/60 Hz- • 1.5 KW (for glove box); 2.5 KW (for four furnaces)

- • Total: 4.0 KW

|

Glove-Box

|

• Gas purification station is integrated to ensure a low O2 & H2O environment (<1ppm) in the glove box.- • Case Material: Stainless steel 304 with 3 mm thickness

- • Chamber dimension: 1200 mm L x 740 mm W x 900 mm H

- • Openable front window panel (tempered glass, 8 mm thick) for easy device loading

- • Please click Picture left for detail specification

|

Electromagnet Release &

Quenching Media Tank

|

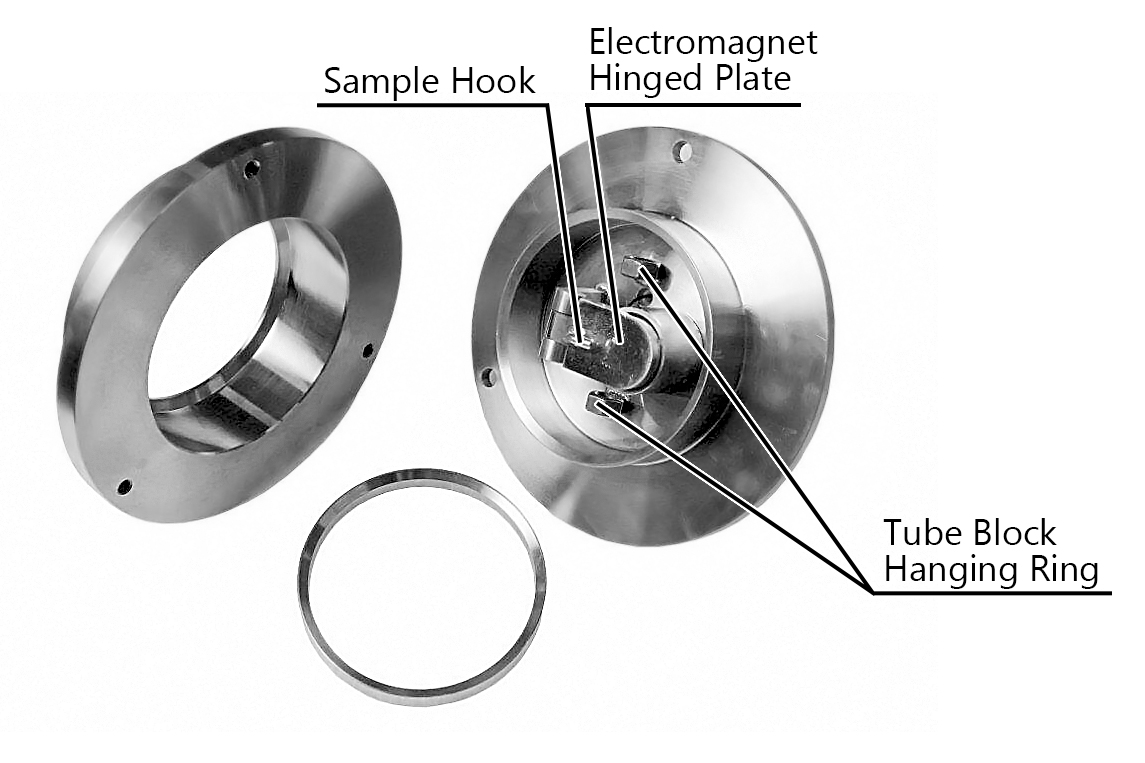

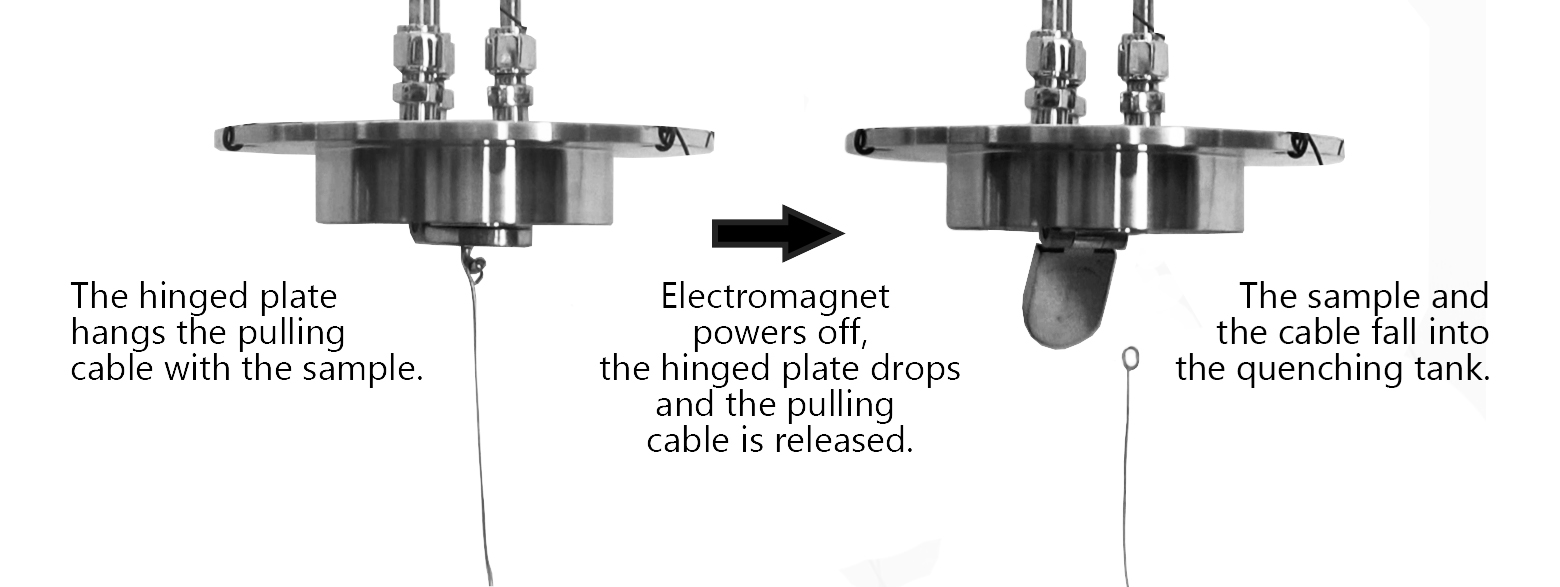

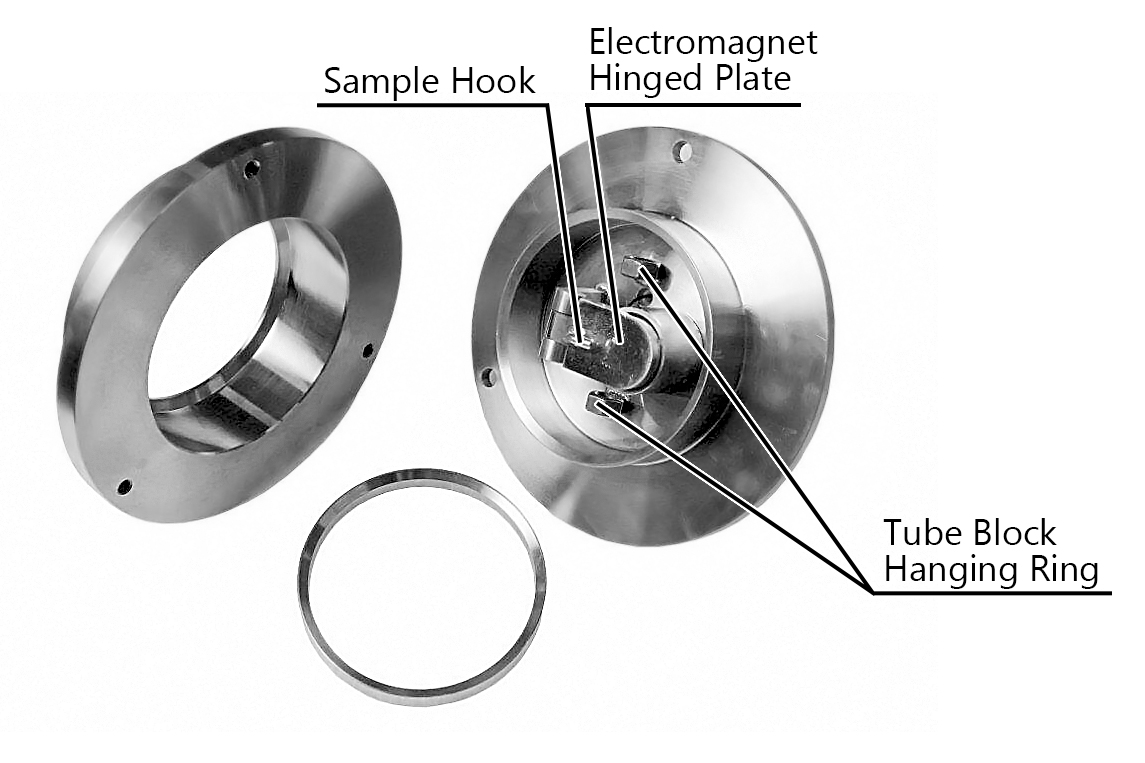

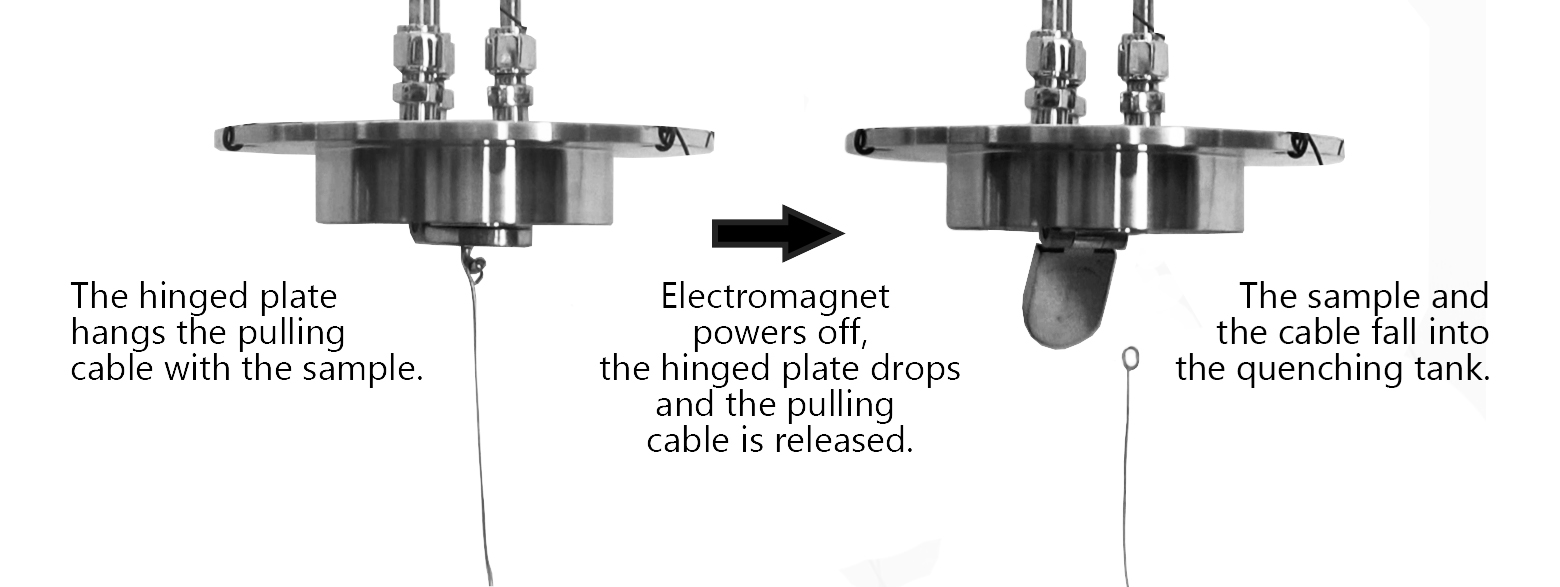

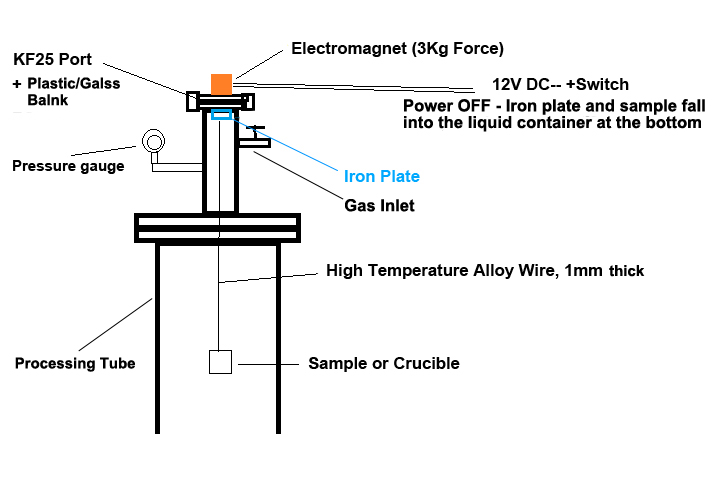

• 4 sets of Electromagnet Auto-drop Mechanism are installed with the furnace for sample release under atmosphere controlled environment.- • Hinged plate with a hook & cable can hang the sample in the hot zone for heat treatment.

- • Hinged plate releases when the electromagnet is powered off. Then the sample falls into the quenching tank.

- • Rings attached to the top flange for hanging the quartz block to prevent heat dissipation.

- • Improved top flange design allows easy sample reload without uninstalling all parts of the flange.

- • Bottom flange is connected with a 4" gate valve ( electrically operated ) via CF-100 adaptor.

- • Four gate valves are connected to with a quenching media container separately

- • Four quenching container are airtight and connected to a vacuum pump .

- • Note: It is suggested to use oil (such as diffusion pump fluid) as quenching agent if quenching under vacuum.

|  |  |  |  |  | | 1. Flange Structure | 2. Flange Operation | 3. Gate Valve | 4. Quenching Tank | 5. Quenching | 6. Pulling Cable |

|

France Specs

|

• 4 verical furnaces installed in the bottom of glove-box for standard version. 8 furnace max ais available

upon request.- • Working Temperature: 1400oC < 30 minutes; <1350oC continuous

- • Heating Rate ≤ 10oC /min

- • Heating Elements: 4 pcs 1500°C rated SiC

- • Processing Tube: alumina tube ID:22 mm x OD: 25 mm x Length: 450 mm (included)

- • Heating Zone Length : 6" (152 mm)

- • Constant Temperature Zone: 50 mm (+/- 2°C)

- • Temperature Accuracy: +/- 1.0°C

|

Temperature Controllers |

• Four programmable digital temperature are included and operated outside glovebox - • Built in PID Auto-Tune function with overheating & broken thermocouple broken protection.

- • Over-temperature protection and alarm allow for operation without attendant(s).

- • +/- 1 ºC temperature accuracy.

- • RS485 Communications Port.

- • PC control software and interface module are optional. Please select the package option.

|

Water-Cooled Flanges

|

• Both top and bottom flanges have water-cooling jacket (See left picture), which cools and preserves the O-ring

sealings on the flange during high-temperature operation- • Please click the picture below to order water chiller at the extra cost

|

Vacuum Level

|

• 10^-2 torr can be achieved by a mechanical pump- • 10^-4 torr can be reached by a turbo pump

- • 10^-5 torr can be reached by faster turbopump system

- • Note: Vacuum pump is not included. Please click Pic below to order separately

-

|

Dimension

|

Please click the image below to enlarge

|

Net Weight | ~800lbs |

Shipping weight | ~1400lbs |

Warranty

|

One-year limited warranty (Consumable parts such as heating elements, processing tubes

and o-rings are not covered by the warranty)

|

Laptop, software & WiFi Control (Optional)

|

• Brand new laptop with Microsoft Window 10 and Microsoft Office 2013 (30 days free trial) for immediate use.- • Labview Based Temperature Control System (EQ-MTS01) enables user to edit temperature profile, manage

heat-treatment recipe, record and plot data for MTI furnaces. - • A wireless remote control provides up to 300 meters operating range.

- • Above features are available upon request at an extra cost (up to $1,000). Please contact us for more information

- • Note: The software is only compatible with MTI’s Yudian Temperature Controller

|

Compliance

|

• CE Certified- • All electric components ( >24V) are UL / MET / CSA certified

- • The furnace is ready to pass NRTL certification (UL61010) or CSA certification at extra cost.

|

Application Notes

Click here to learn how to install a gas regulator.

| - • The tube furnaces with mullite tube are designed for using under vacuum and low pressure < 0.02 Mpa / 0.2 Bar/ 3 PSI

- • Never use graphite crucible in alumina tube.

- • Attention: A two-stage pressure regulator must be installed on the gas cylinder to limit the pressure to

below 3 PSI for safe operation. Click here to learn the installation of a gas regulator. - • Never heat the furnace while the gas release valve is closed and a positive pressure condition exists within the

furnace chamber. The pressure gauge must be used to closely monitor the chamber condition at all times during

the heating process; please open the gas release valve immediately once the chamber pressure has reached

over 3 PSI to prevent unforeseeable damages. - • The flow rate for gasses should be limited to < 200 SCCM ( or 200ml/min )

- • Vacuum limit definition for all mullite tube furnaces: * Vacuum pressures may only be safely used up to 1300°C

|

Operation Instructions | |