Furnace

|

Structure

|

• Double layer steel casing with air cooling.

• High purity alumina fiberboard liner for energy cost effective operation.

• Three heating zones with three independent temperature controllers.

• Vacuum and gas mixing system are located in bottom Mobile cart with 4 wheels.

|

Heating

Element

| Fe-Cr-Al Alloy doped by Mo

|

Max.

Heating

Temp.

| 1200°C

|

Continuous

Heating

Temp.

| 1100°C

|

Max.

Heating

Rate

| <=20°C/min

|

Heating

Zone

Length

| Three zones: (880mm, 35" in total)

Zone 1: 220 mm + Zone 2: 440 mm + Zone 3: 220 mm

|

Constant

Temp. Zone

| 20" (500 mm) length (three zones at equal temperature within +/- 1°C)

|

Tube Size

and

Materials

| Fused Quartz Tube

100 mm O.D x 92 mm ID. x 1400 mm

|

Temp.

Controller

|

Three precision digital temperature controllers programmable with 50 segments,

which control each heating zone separately.

PID adjustable with auto tune function to ensure temperature stability within +/ - 1

oC.

Full protection in each controller for over-temperature and broken thermal couple.

|

Thermocouple

| Three K-type thermocouples

|

Power Input

| AC 208~240V, Single Phase, 50/60Hz, 7KW max.

|

Vacuum Fittings

|

The Standard vacuum accessories include:

- • Two stainless steel vacuum flanges with KF-25 pump connector, two needle valve and one

1/4"

Swagelok tube connector. - • Six pieces of high-temperature silicone O-ring for using under 300°C.

- • Two pairs of alumina thermo-blocks are included for protecting flange from heat radiation.

- • One KF-40 vacuum bellows

- • Three KF-40 quick clamps.

- • Two KF-25 quick clamps.

|

HV Station

High Vacuum Station

|

Structure |

Mobile cart size: 600 (L) x 600 (W) x 700(H), mm

Max. Loading: 600 Lbs on top

Molecular pump control Panel : LCD digital

Inside: Pfeiffer vacuum pump Made in Germany

Vacuum sensor is included

|

Vacuum

sensor | The vacuum sensor has a KF-25 connector.

High vacuum gauge (measuring range 10^-8 mbar ~ 10^3 mbar)

|

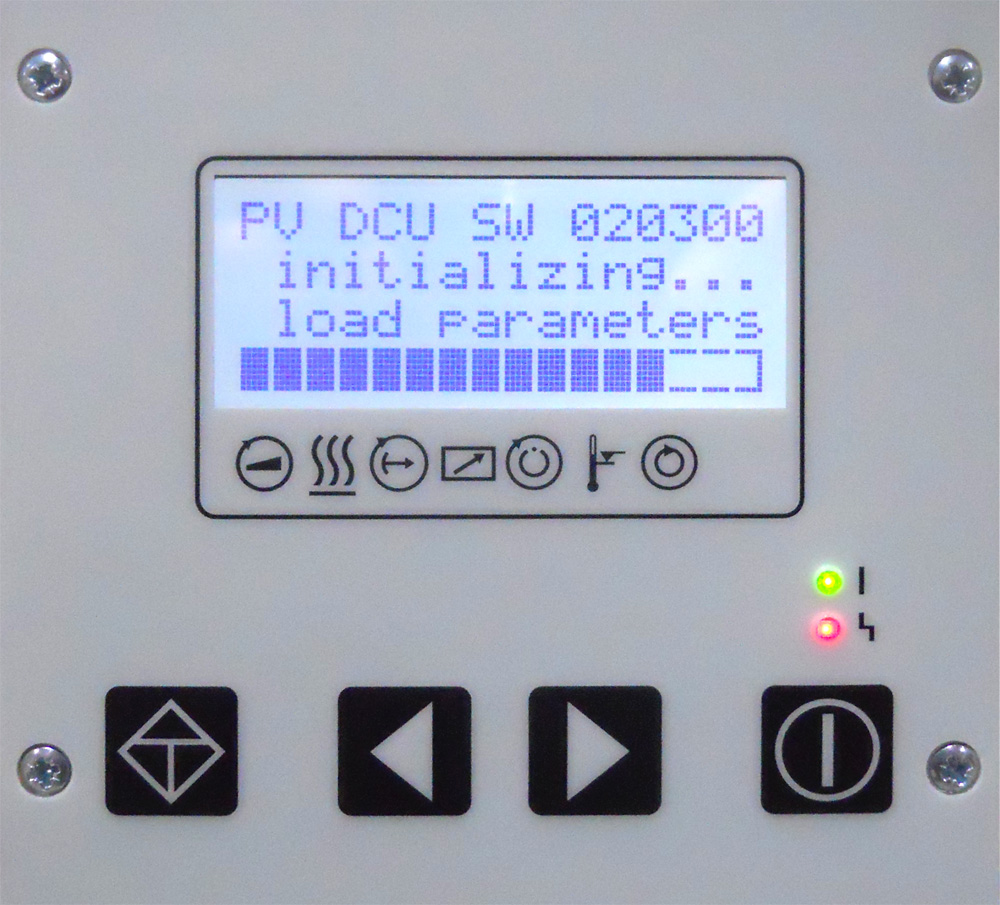

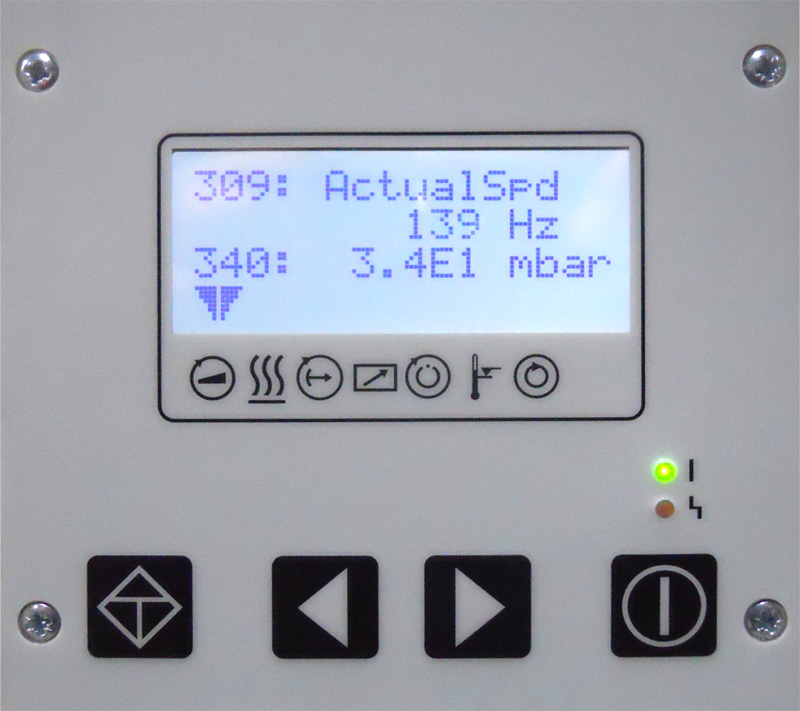

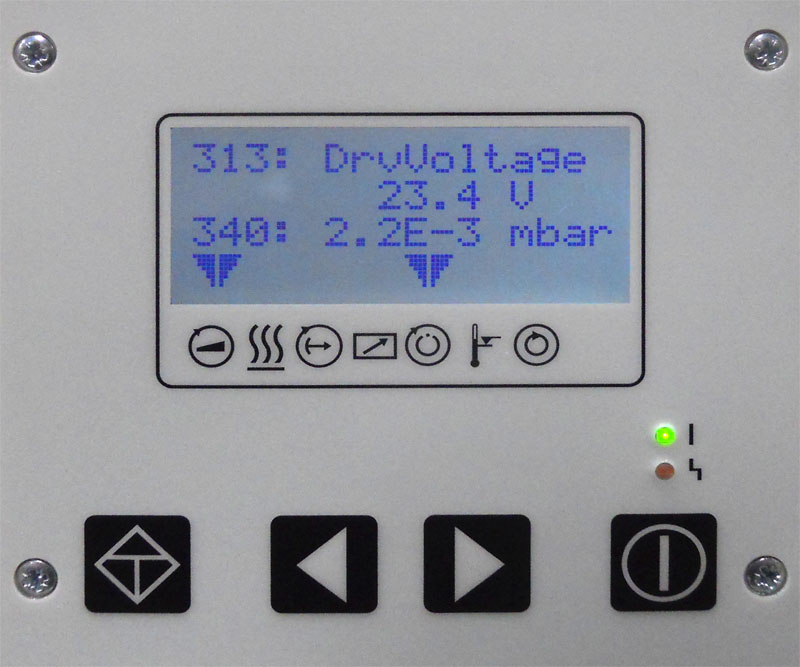

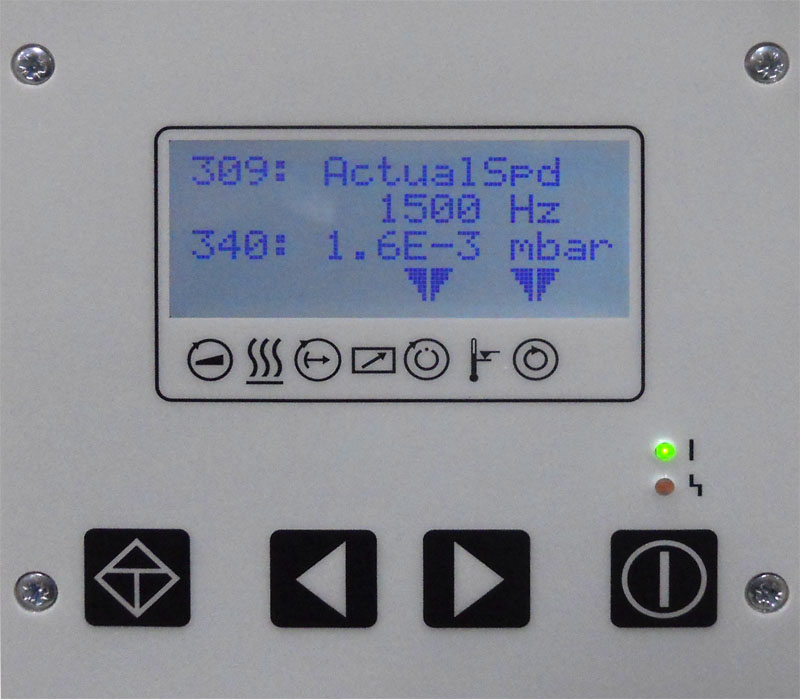

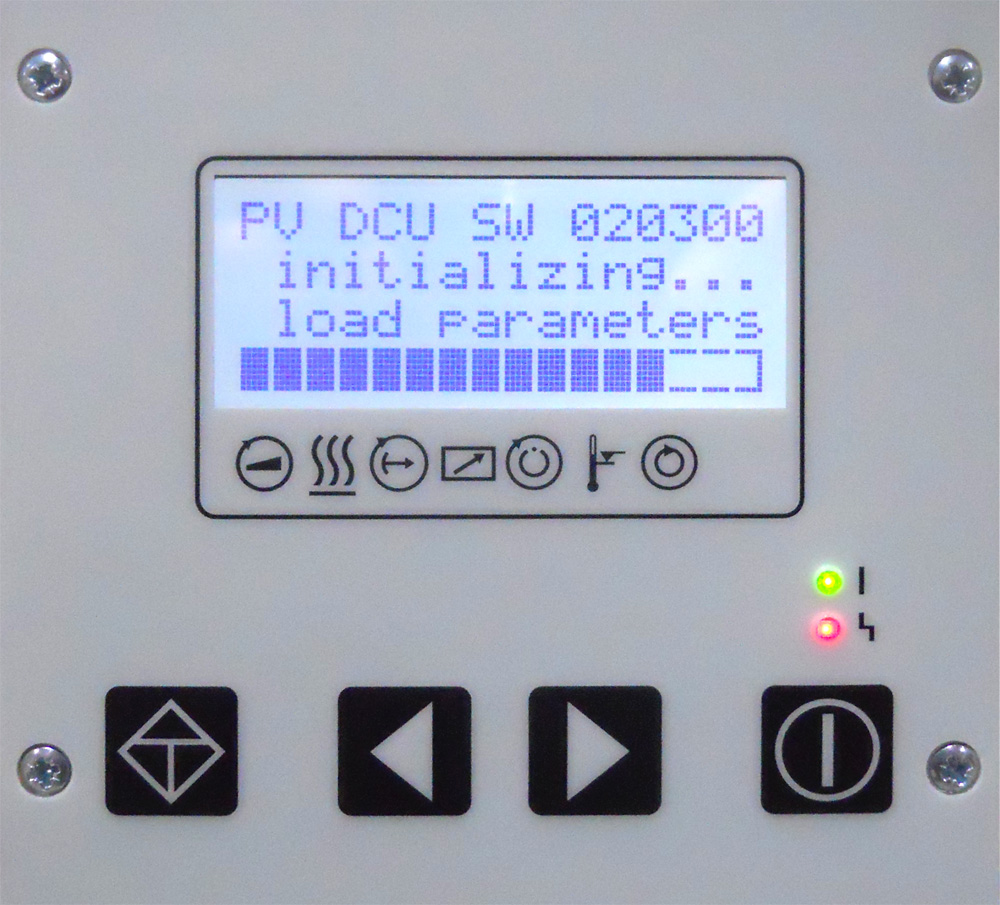

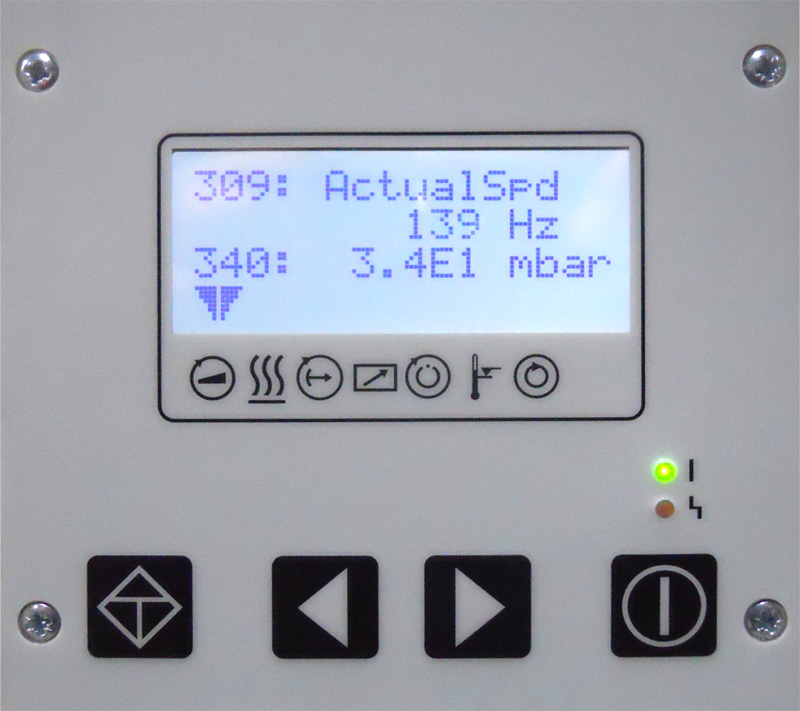

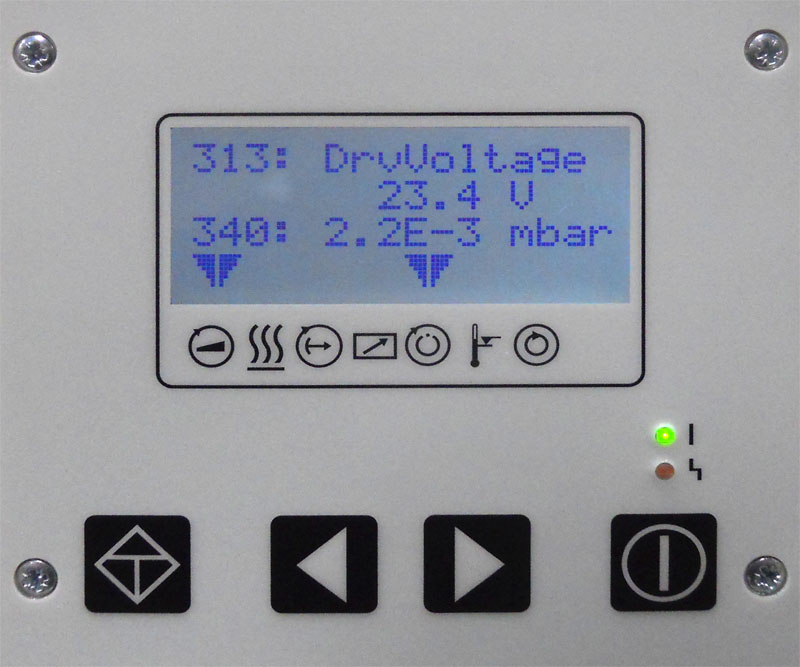

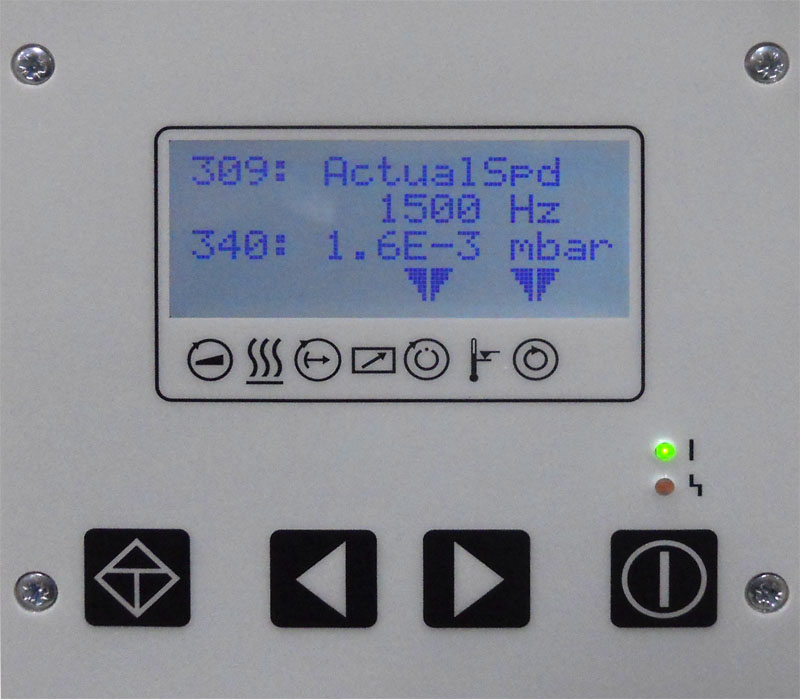

Control

Panel |

One button operation - the diaphragm pump and the turbo molecular pump will

start after pressing "start" button.

System controlled spinning speed - the controller will control the speed of the

turbine spinning up and down according to the vacuum level and leaking rate of

the reaction chamber.

Self-protection - the system will protect the pump from damage by overheating

and overcurrent if the leaking rate of the reaction chamber is too high to achieve

the high vacuum.

LCD screen - double lines parameters checking interface make the working easier

to be handled.

|  |  |  |  | Self-testing

| Spinning up | Error report

| Voltmeter

| Full speed |

|

Volume Flow

Rate | Nitrogen N2 33 L/s

Helium He 39 L/s (2340L/minute)

Hydrogen H2 32 L/s |

Working

Range | From 1000 mbar to <1E-7 mbar |

Ultimate

Pressure | 10^-5 torr (with tube furnace)

|

| Power Input | 110V AC or 220V AC switchable, 50/60Hz |

Power

consumption | Duration/Max power: 100/110Watt |

MFC Station

Mass Flow Controller

|

9 precision mass flow meters controllers are installed in the bottom mobile cart with the digital

display panel of +/-1.5% of Full Scale.

- • Controller 1: 0~100 SCCM

- • Controller 2: 1~199 SCCM

- • Controller 3: 1~199 SCCM

- • Controller 4: 1~499 SCCM

- • Controller 5-9: measuring range can be customized based on customer's request

The flow rate control range is available for customization. Please contact us for detail information.

|

Optional Parts |

• Click picture below - left to order bubbler or evaporator for CVD

|

Gas Pipe Connect

|

• One 1/4“ Swagelok tube connect is installed in the left flange as the gas inlet.- • Each MFC Station has four 1/4" Swagelok tube connects. And four on/off valves for each

gas route.

The fifth one is used as the gas outlet. - • The 1/4" PTFE gas pipe is included in the standard package.

- • [Optional] If Stainless steel 1/4" gas tube is needed, please click here to order.

|

Shipping Info

| Dimension

| Furnace: 550 x 380 x 520mm

MFC Station: 600 x 600 x 700mm

HV Station: 600 x 600 x 700mm

|

Weight

| Net weight: 100Kg

Shipping weight: 350 lb (two pallets)

|

Warranty

|

One year limited warranty (Consumable parts such as processing tubes, o-rings, and heating elements

are not covered by the warranty, please order the replacement at related products below.)

|

Compliance |

• CE/UL/CSA Certificate- • Please select the certificate in options bar:

- º CE Certificate & UL/CSA ready to pass UL/CSA certificate at extra cost

- º UL certificate - UL approvals (UL 61010)

|

Warning

Click here to learn the

installation of a gas

regulator

|

• The tube furnaces with quartz tube are designed for using under vacuum and low pressure

< 0.12 MPa (absolute pressure)- • Attention: A two-stage pressure regulator must be installed on the gas cylinder to

limit the pressure to below 3 PSI for safe operation.

Click here to learn the installation of a gas regulator. - • The flow rate for gasses should be limited to < 200 SCCM (or 200 ml/min) for reducing

thermal shocks to the tube - • Vacuum limit definition for all quartz tube furnaces: * Vacuum pressures may only be safely

used up to 1000°C

|

| Operation Instructions |   Quick test instruction Quick test instruction |