Features

| - Compared with other brands of the planetary centrifugal mixer, MSK-PCV-300 has the following unique features:

- Mixing under vacuum for deaeration

- Dual containers for larger quantity

- Minimized contamination (no metal mixing blade)

- Centrifugal acceleration: 600 g Max.

- Sample Materials

- Nanopowders, ceramic powders

- Slurry

- Paste

- Mechanical alloying with special alloy jars (optional)

|

| Voltage Input | - Single Phase AC 208 - 240V, 50/60 Hz

|

| Power | - Maximum: 1350 W

- Motor Power: 750 W

|

Mixing

| - Planetary Centrifugal Vacuum Mixing

- The centrifugal force of rotation and revolution induces convection, homogenizing the materials

- With the vacuum pressure, submicron air bubbles can be efficiently eliminated from the materials

- Max viscosity: 80,000 Pa S

|

| Vacuum Capability | - Pumping Rate: 165 L/min

- Ultimate Vacuum: -95 kPa

- Built-in vacuum pump with integrated control

|

| Speed | - Fixed speed ratio (0.6X between main plate revolution and container rotating)

- Sample Platen Rotation (revolution motion): 600 rpm - 2,000 rpm (adjustable)

- Container Spin (rotation motion): 360 rpm - 1,200 rpm (fixed at 0.6X of the revolution speed)

|

| Containers and Counter-Weights | - Two standard containers and counter-weights are included

- Two 300 ml containers with gas vent, made of high-density Polyethylene (Pic. 1, 2)

- Counter-weights (10, 20, 50 g) with adapter, made of high-density Polyethylene (Pic. 3)

-

Pic. 1 Pic. 1  Pic.2 Pic.2  Pic. 3 Pic. 3

|

Optional containers

| - Two 100 ml containers (not included) with adapter and gas vent, made of high-density Polyethylene (Pic. 1)

- Two 30 ml containers (not included) with adapter and gas vent, made of high-density Polyethylene (Pic. 2)

- 26 mm Dia. adapter for 30 mL syringe (not included), made of high-density Polyethylene (Pic. 3)

- Two 3-container-sets (10ml) in one adapter are available for high throughput research (6 samples per batch)

- You may also order the special alloy jars for smaller sized ball milling applications (the rightmost pic, click here to see a video)

Pic. 1 Pic. 2 Pic. 3 Pic. 4 Pic. 5 Pic. 6 |

| Max. Mixing Volume and Weight | Container | Max Sample Volume | Max Sample Weight | Max Gross Weight (Container Included) | 300 mL | 150 mL | 140 g | 300 g ( wet mixing) | 100 mL | 50 mL | 45 g | 80 g (adapter not included) | 80 mL(SS) | 60 mL | 90 g | 300 g (adapter included) | 30 mL | 15 mL | 12 g | 20 g (adapter not included) |

- Warning: overload may damage the device. Please follow both the volume and weight limit as above when loading the sample.

|

Control Panel

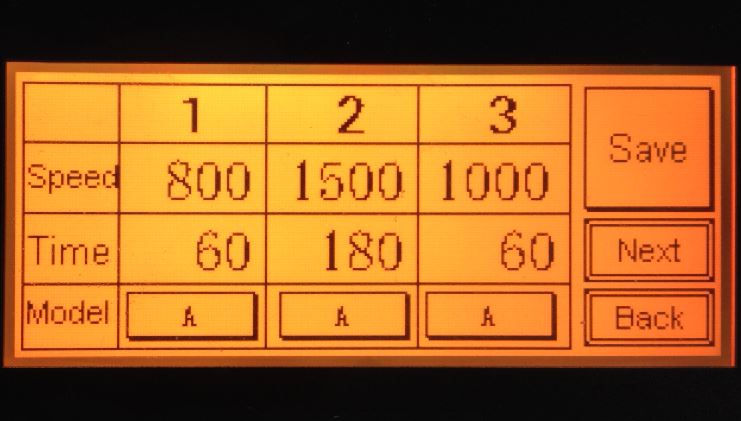

Fig.1 Fig.1

Fig.2 Fig.2

| - Touch screen control panel to program speed and time

- Store up to 6 programs in memory, as shown in Fig.1

- 3 programmable segments, as shown in Fig.2. For example:

- 800 rpm revolution speed (480 rpm rotation speed) for 60 sec;

- 1500 rpm revolution speed (900 rpm rotation speed) for 180 sec;

- 1000 rpm revolution speed (600 rpm rotation speed) for 60 sec.

- The maximum running time for each segment is 200 sec. The maximum total running time is 600 sec

- The rotation direction could be either clockwise (mode A) or counter-clockwise (mode B)

|

| Safety and Protection | - Safety warnings and interlocks are integrated. The unit automatically stops when

- The unit is overloaded with the sample

- The sample is loaded in an unbalanced way

- The top cover is opened

|

| Warranty | - One-year limited standard warranty with lifetime technical support

|

| Dimension | |

| Weight | |

| Shipping Weight & Dimensions | |

Operation Video and Instructions

|  How to mixing How to mixing  How to ball milling How to ball milling |

| Application Notes | - Always use the mixer on a level & stable surface for best performance and maximum safety

- Do not use the mixer in a hazardous atmosphere, or with flammable, explosive, corrosive, poisonous material! Check the chemical resistance of the container with different materials before loading the sample!!!

- Do not overload the mixer! Stop the mixing operation immediately if abnormal sound/vibration is observed

- Use a digital balance to make sure the sample loading is balanced before mixing

- Double-check if the containers are mounted correctly and securely before mixing

- Do not open the cover lid until the rotation has completely stopped! Do not retrieve the containers and/or put a hand close to the mixing fixture while the rotation has not completely stopped!

- Only use the included containers for the mixing operation! Please make sure there is no foreign object in the mixer before mixing

- Please click underline to learn Centrifugal Force calculation

- Please do not use it under Ar gas. Please consider our MSK-PCV-310AR if Ar gas is required

|