Working Voltage | 208 - 240 V AC, 50/60Hz, Single Phase

|

Max. Power Consumption | 4 KW ( 30A Air breaker required ) |

Max. Coating Width | 250mm |

Thickness adjustable range | 0-5mm

|

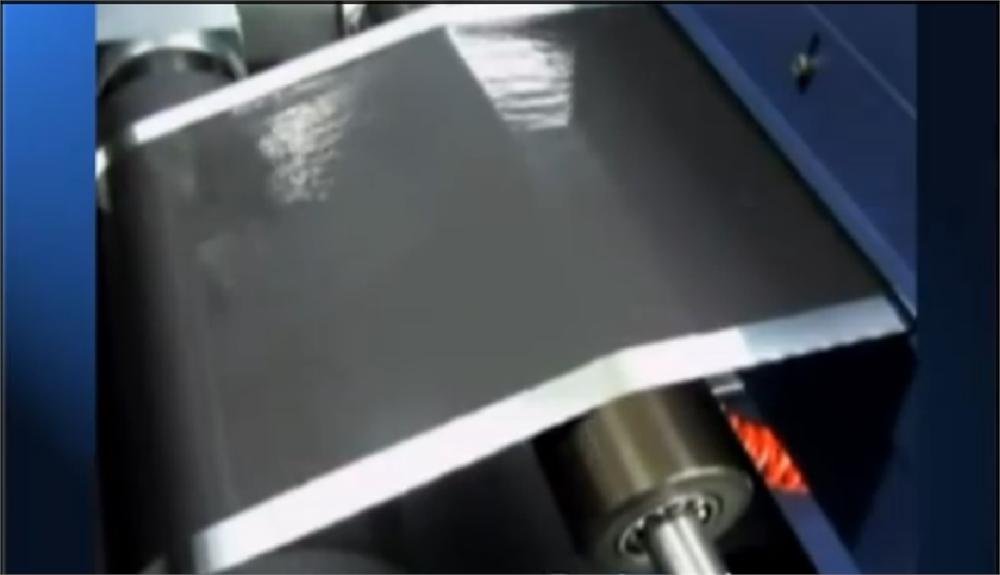

Coating thickness (after drying) | 30 - 200um (for most kinds of battery electrode coating material)

Note: The dried coating thickness results vary depending on the physical property of the coating material.

|

Thickness Precision | ± 3µm (± 5µm at edges)

|

Coating Speed | 0-750 mm / minute |

Max. Drying Temperature

| 120°C

( Using a 240V transformer, can reach 150°C max.) |

Temperature Accuracy | ±1°C |

Heating Zone Length | 710mm (28") |

Reeling/Unreeling Shaft

| 75mm (ID) |

Max. Reeling/Unreeling Diameter | 250mm (OD)

|

Max. Coating Length

| - Depending on the coating and substrate thickness.

- Typically, 10um thick foil with 100um coating can get 600 meters of electrode length coated per run

|

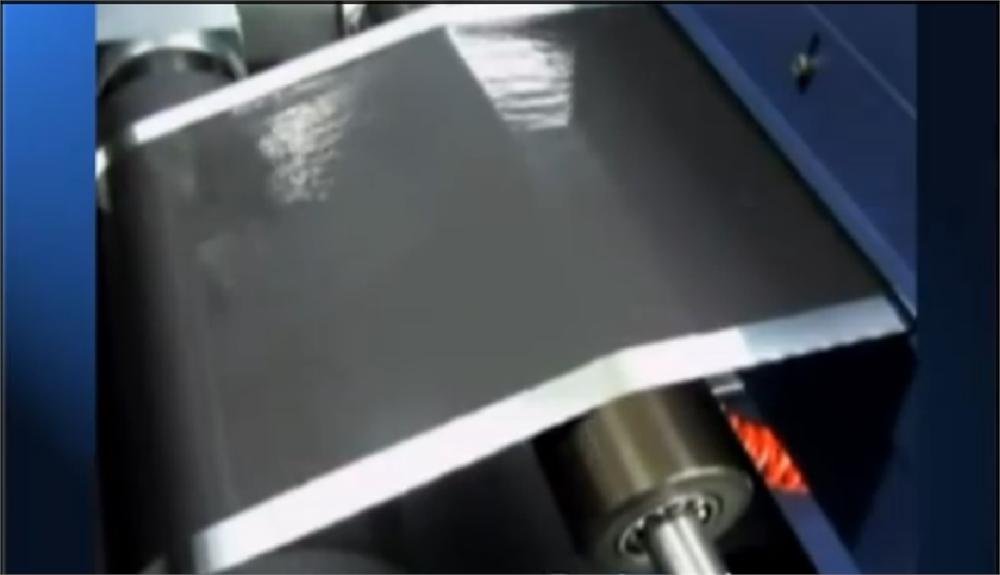

Coating Modes

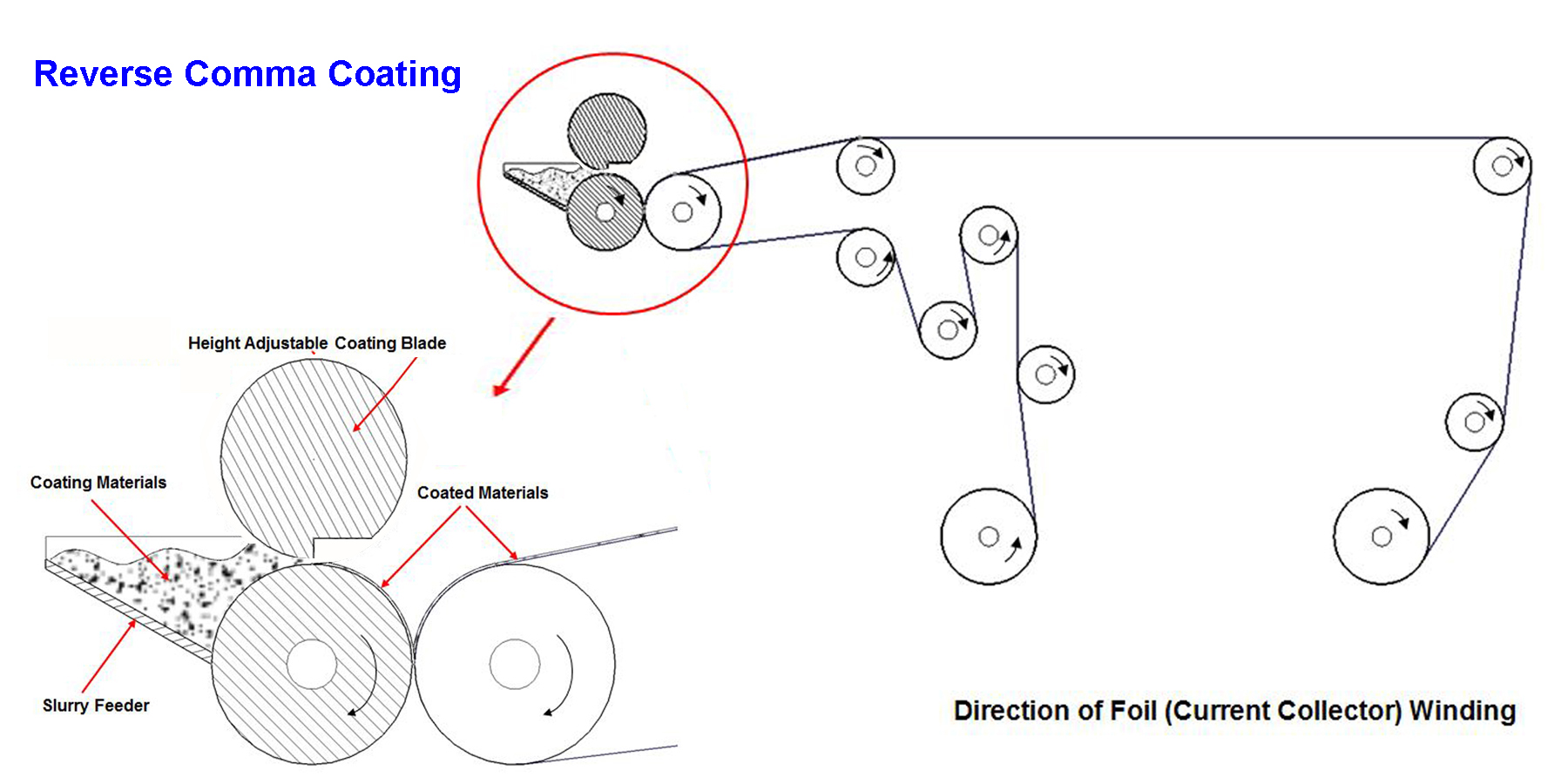

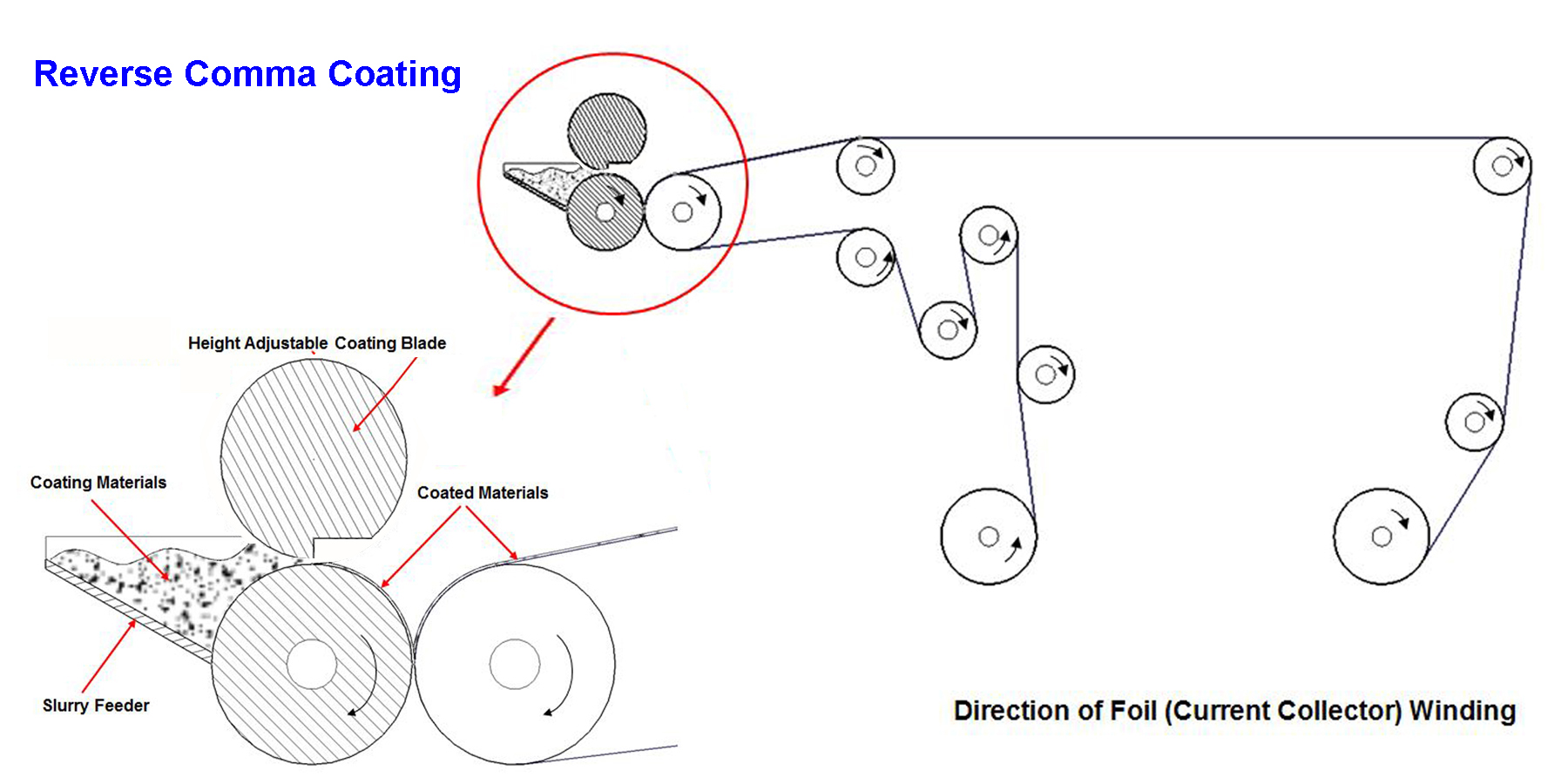

| - Using transfer coating technique ( Reverse comma ) for better uniformity ( Click Pic below -left for detail )

- Two available coating modes selectable on the control panel.

- Continuous mode

- Intermittent coating ( system performs coating, stops, coats again and so on. The length of the coating and break segments can be specified by the user ).

|

Slurry Stirring

| SS316 Moving Rod

|

Exhaust Port Size | 127mm O.D |

Compressed Air | 0.5-0.8 MPa (Air compressor not included. Please click here to order)

Attention: If a gas cylinder is used instead of air compressor(pic2), a two-stage pressure regulator(pic1) must be installed on the gas cylinder to limit the pressure within the required working range for safe operation. Click here to learn the installation of a gas regulator.

pic1 pic1  pic2 pic2

|

Optional

| - You may order Dual-Filtration System for NMP Vapor and connect it to the coating system for keeping environmental healthy. Please click Pic.1 for details.

- Atmosphere plasma cleaning add-on for the substrate is available upon request. Such a surface treatment will activate and increase the energy of the substrate surface and thus enables a better adhesion & bonding to the coating materials. Please click Pic.2~3 and Video.1 for more details.

Pic.1 Pic.2 Pic.3 Video.1

- Test the flexibility of the coated electrode with EQ-MBT-12-LD mandrel bending tester. ( Click pic.4 in below for detail.)

- You may use Precision Peristaltic Slurry Feeding Pump for continuous slurry delivery during the roll to roll coating process.( Click Pic.5 & Pic.6 in below to order )

- You may order the Magnetic De-ironing Filtration system (Pic.7) for optimizing the battery electrode slurry condition before the coating process.

Pic.4 Pic.5 Pic.6 Pic.7

|

Product Dimensions |  1620mm ( L) x 950mm (W) x 1100mm (H) 1620mm ( L) x 950mm (W) x 1100mm (H)

|

Compliance | - CE Certified

- NRTL (UL61010) or CSA certification is available upon request at extra cost.

|

Warranty | - One Year limited warranty with lifetime support

- Rusting and damage due to improper storage condition or maintenance are not covered by warranty

|

| Operation Manual & Video |     |

| Application Notes | - Please use Acetone to clean and dry the doctor blade, slurry feeder, and roller to avoid rusting

- Please contact us for compatibility of slurry solvent and rubber roller of the coater.

- Customers are welcome to visit our facility to receive technical training before shipping of equipment (Please schedule an appointment with us in advance)

- On-site Training is available for customers at extra cost.

- Test the flexibility of the coated electrode with EQ-MBT-12-LD mandrel bending tester. ( Click pic.1 below for detail.)

- PET Film with single side Si Coating is available for Roll-to-Roll tape /slot die/ Micro Gravour casting of Li- ion battery electrode slurry, ceramic, functional resin, ink, and others. Please click the Pic.2 in below to view the product.

Pic.1 Pic.2 |

| Net Weight | 1000 kg (2200 lbs) |

| Shipping Dimension | 70" x 45" x 55" |