|

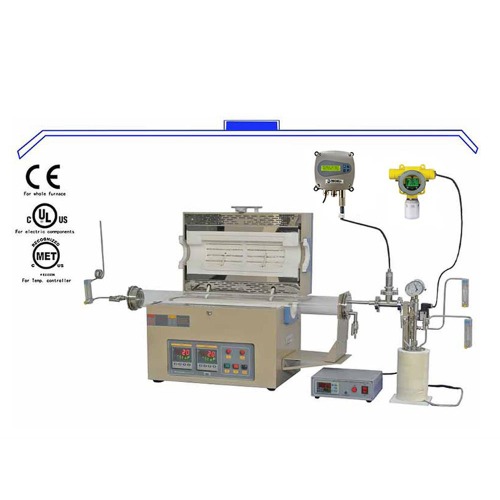

• Double shell casing with cooling fans

- • High purity alumina fibrous insulation for max.

energy saving

- • Split cover enables faster cooling and easy operation

- • Hydrogen detector and solenoid valve are included

for safety measures

- • The liquid evaporator is heatable with a precision

temperature controller to produce a mixing of

hydrogen and liquid vapor.

- • The hydrogen gas furnace must be placed under a

fume hood which is not included.

|

Power | 4 KW Max |

Input Voltage | AC 208 - 240V single phase (30A air breaker is required) |

Heating Elements | FeCr27Al7MO2 |

Heating Zone Length |

• Two heating zones: 8" (200 mm) length of each

zone, 16" (400 mm) total

• Constant temperature zone: 150 mm within +/- 1oC

when two zones are set at same temperature

|

Temperature Uniformity | +/- 1°C in heating Zone |

Continuous Working Temperature | 1100°C |

Recommended Heating Rate | 10°C /min |

Processing Tube and Flanges |

• High purity quartz tube: Φ80 (OD)×Φ74 (ID) ×

1000 L, mm

- • Vacuum flange: SS304 flanges are included to

achieve vacuum up to 10^ - 5 torr by turbopump.

|

Temperature Controllers

|

• Two MET certified digital temperature controllers

with 30 programmable segments for precise control

of heating rate, cooling rate and dwell time.

- • Built in PID Auto-Tune function with overheating &

broken thermocouple protection.

- • Over temperature protection and alarm allows for

operation without attendant(s).

- • +/- 1 ºC temperature accuracy.

- • RS485 port is installed in front of panel for PC

connection

- • PC control module and software is included

forcomputerized temperature control.

Click here to review detailed information.

|

Float Flow Meter

|

• Two flowmeters 50-500ml/min are built on the gas

inlets.

- • One flowmeter is for Hydrogen delivery while the

other is mainly for CVD gas with liquid vapor

- • The extra flowmeter is available upon request at

extra cost.

- • You may consider using our MFC gas delivery

station 1 - 9 channel for more accurate gas control

|

Bubbler/ Liquid Evaporator

|

• Such a liquid evaporator is suitable for liquid sources

and chemical precursors delivery in CVD processes.

- • One stainless steel container is included with

capacity of 600 ml ( 80OD x 200H, mm)

- • The container is inserted into a small cylindrical

heater with thermal insulation

- • The container can be heated up to 250°C and

controlled by a precision programmable temperature

controller.

- • Two SS needle valves and one pressure gauge are

built on the container (click picture below to see

details)

|

Humidity Monitor

( included) |

• One precision humidity monitor is connected to the

processing tube flange with KF25 adaptor

- • Measurement range : 0 - 100% RH with 1.5%FS

accuracy, or -60º ~ +60º DP with +/-0.3º accuracy.

- • Tips: You may adjust the evaporator's (water inside)

temperature and H2 gas flow rate to achieve desired

humidity level.

|

Hydrogen Detector System

(included) (included)

|

• Working Temperature Range: 40ºF to +149ºF

(-40ºC to +65ºC)

- • Alarm Point: H2 Limited Explosive Line 10% (10%

LEL). Once detecting H2 gas beyond the point, it will

shut off the inlet valve to the H2 automatically.

|

Options for upgrading | |

| Warranty |

One-year limited warranty (Consumable parts such as processing tubes, o-rings, and heating elements are not covered by the warranty).

|

| Compliance |

• CE Certified

- • All electric components ( >24V) of the furnace are

UL / MET / CSA certified, not including other

accessories like liquid evaporator and hydrogen

detector

- • The furnace is ready to pass TUV(UL61010) or CSA

certification at extra cost.

( please click marks below to learn details)

|

Furnace Dimensions | 1400×600×1200mm |

Product Net Weight | 100Kg

|

Operation Instructions | |

Warning

Click here to learn the installation of a gas regulator

|

• Tube furnaces with alumina tubes are designed for

using under vacuum and low pressure < 0.12 atm

(absolute pressure)

- • The flow rate for gasses should be limited to < 200

SCCM (or 200 ml/min) for reducing thermal shocks

to the tube

- • Attention: A two-stage pressure regulator must

be installed on the gas cylinder to limit the

pressure to below 3 PSI for safe operation.

Click here to learn the installation of a gas regulator.

- • Vacuum limit definition for all quartz tube furnaces:

* Vacuum pressures may only be safely used up to

1000°C

|